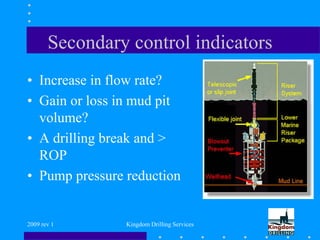

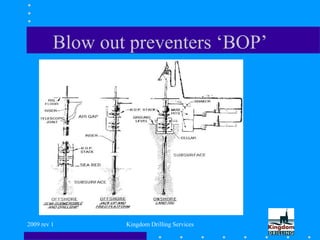

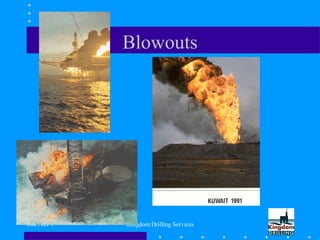

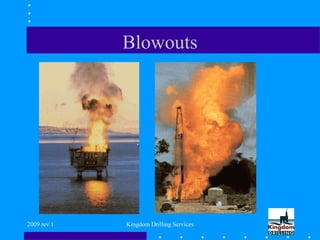

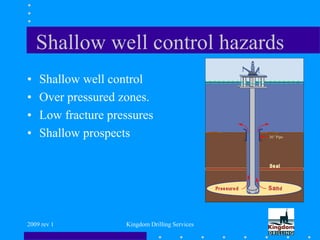

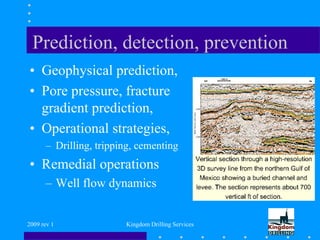

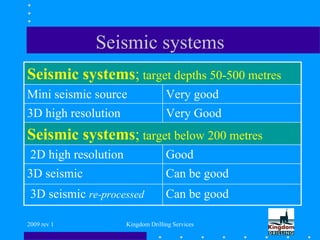

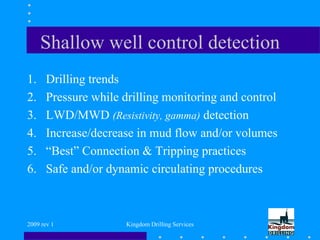

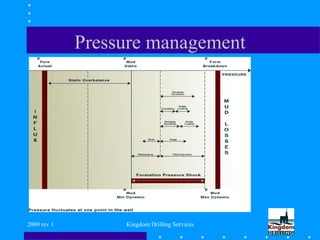

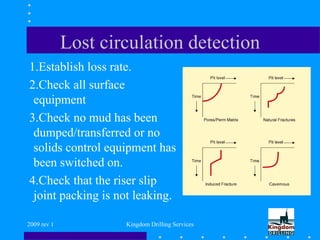

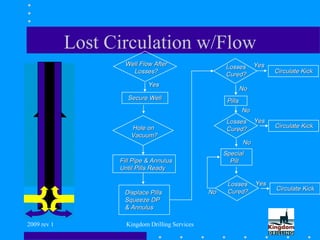

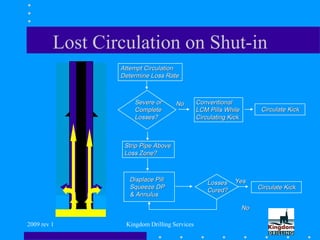

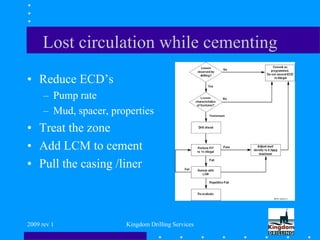

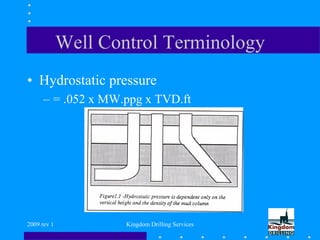

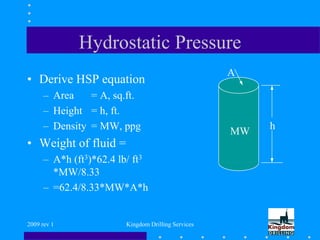

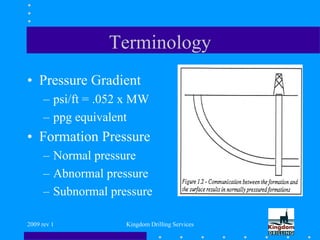

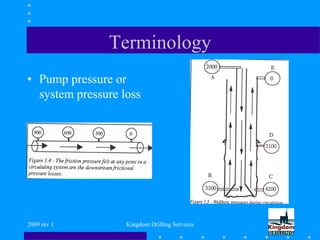

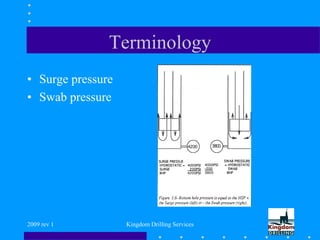

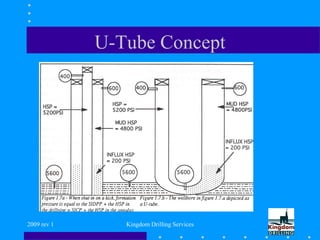

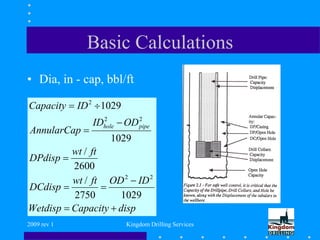

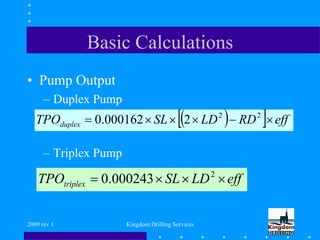

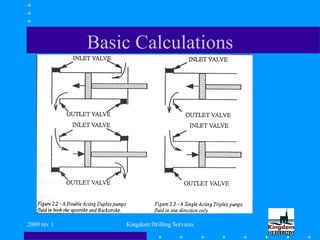

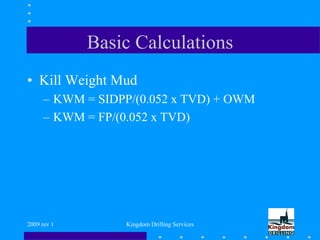

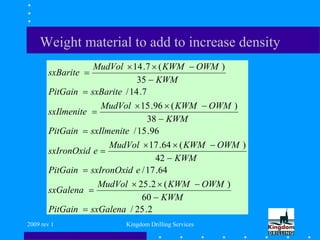

This document provides an introduction to well control from Kingdom Drilling Services. It discusses primary and secondary well control, including maintaining pressure and monitoring flows. Loss of primary control can occur through pressure changes or lost circulation. Secondary control indicators include increased flow rates or mud pit volume changes. Methods for controlling kicks include circulating or bullheading. The document also covers well control terms, blowout prevention, shallow well hazards, and lost circulation detection and remedies.