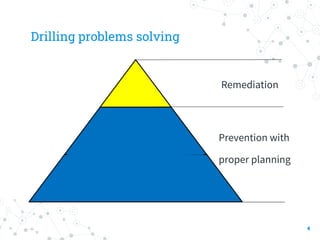

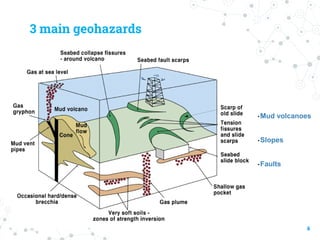

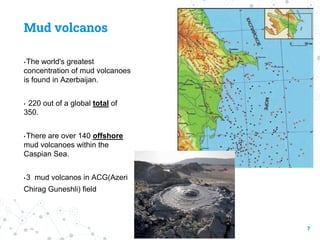

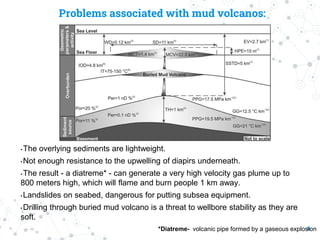

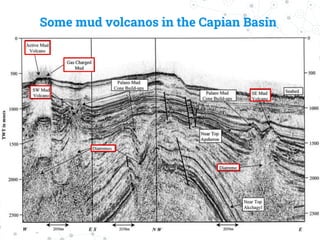

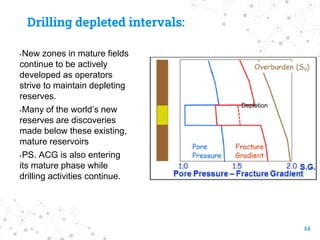

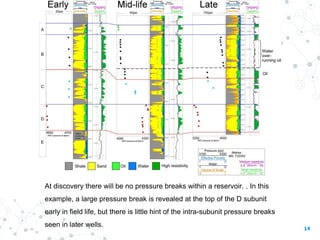

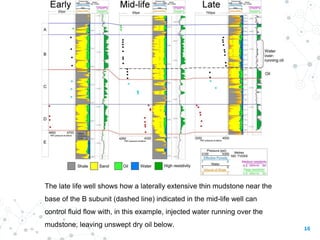

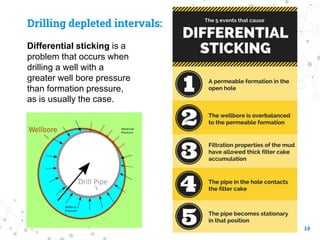

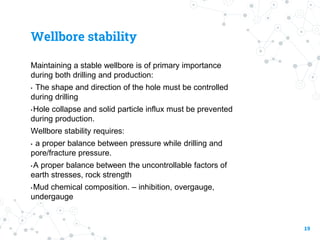

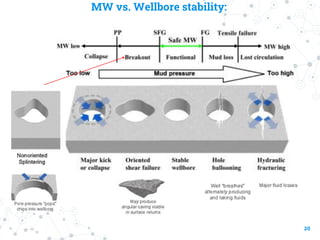

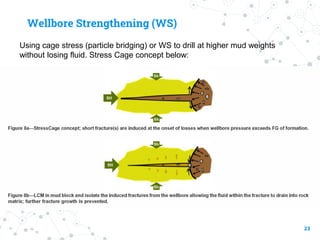

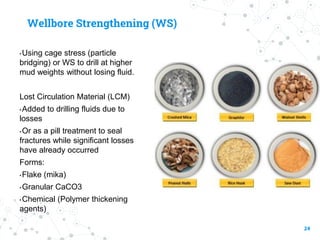

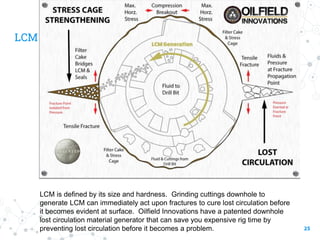

Drilling operations can encounter various problems related to geological uncertainties, wellbore stability issues, and depletion effects. Some key risks include uncertainties in pore pressure-fracture gradient measurements, mud volcanoes causing landslides or weak formations, fault zones providing pathways for fluid flow, and maintaining wellbore integrity in low-pressure depleted zones. Operators address these challenges through careful planning, identifying potential hazard areas using seismic data, selecting appropriate drilling fluid properties, and employing wellbore strengthening techniques and lost circulation materials when needed to prevent fluid losses and wellbore collapse.