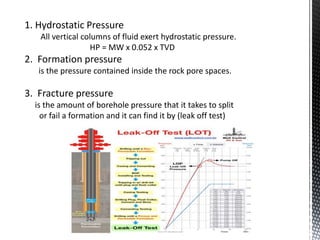

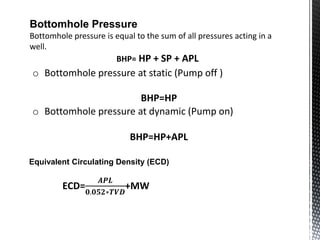

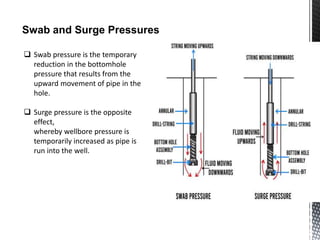

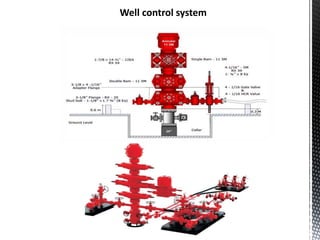

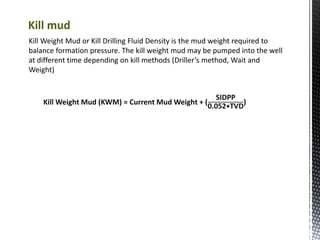

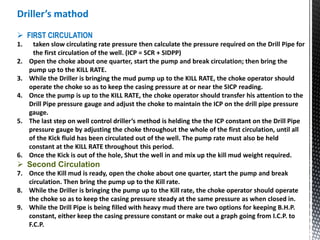

Well control refers to methods used to prevent and manage uncontrolled well flow or kicks during drilling operations. It involves understanding various pressures in the well, responding to warning signs of kicks, and executing shut-in procedures effectively. Proper management, including calculations for kill weight mud and circulation methods, is crucial for maintaining safety and minimizing influxes of formation fluids.