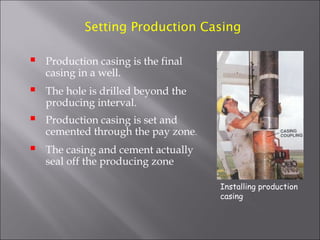

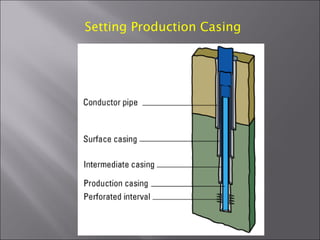

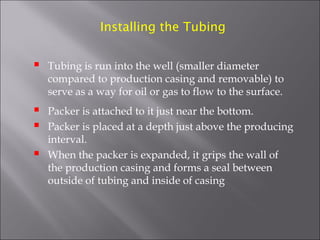

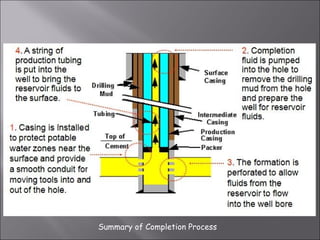

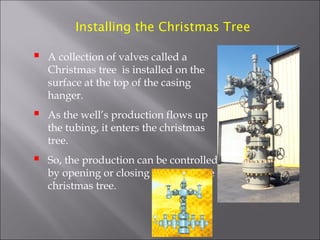

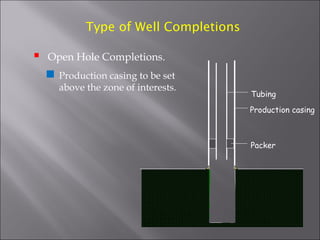

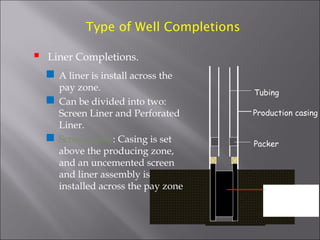

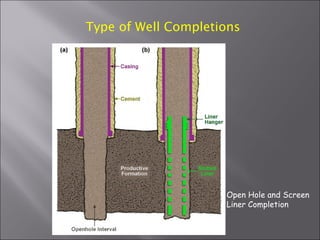

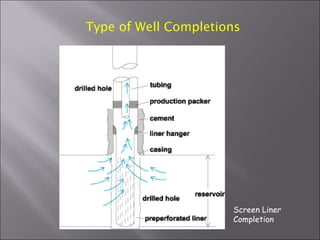

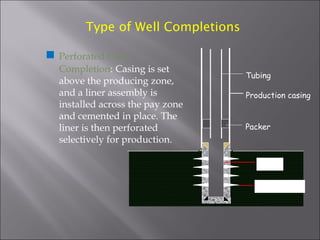

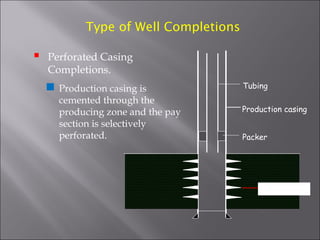

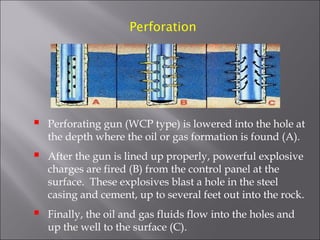

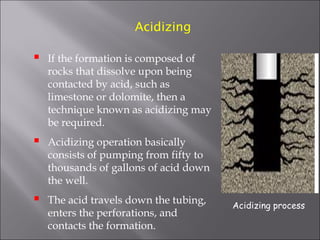

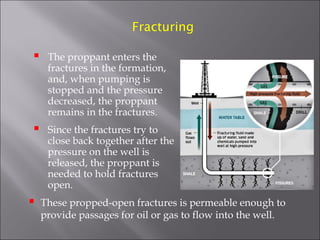

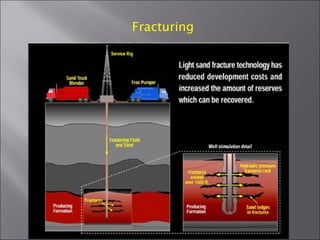

After drilling is completed, wells undergo completion procedures to prepare them for production. This involves setting production casing and cementing it through the target zone. Tubing is run inside the casing with a packer to isolate the production zone. A Christmas tree is installed to control flow. Completion types include open hole, liners, and perforated casing. Perforating creates holes through casing into the formation. Some formations require stimulation like acidizing to improve permeability or fracturing to create conductive fractures held open by proppant. This increases flow into the wellbore.