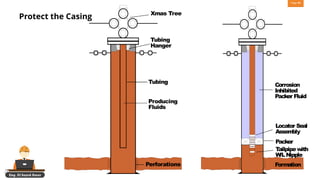

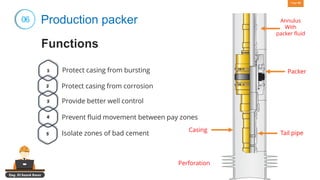

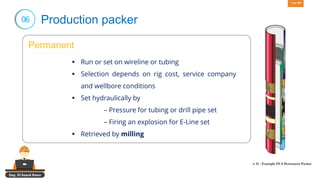

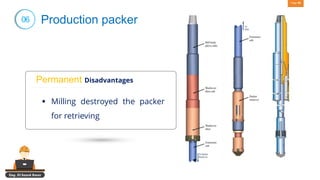

This document contains information about Eng. El Sayed Amer, a petroleum engineer who has worked for Weatherford Drilling International and as a process and production engineer for SUCO and RWE DEA. It discusses production packers, which are subsurface tools used to provide a seal between the tubing and casing. Production packers can protect the casing from corrosion, provide better well control, isolate pay zones, and prevent fluid movement between zones. They are classified as either permanent or retrievable based on whether they can be removed from the well without destruction. The document focuses on the characteristics and advantages and disadvantages of permanent and retrievable production packers.