This document provides an overview of mud weight planning and drilling hydraulics. It discusses selecting the appropriate mud weight to maintain an in-gauge wellbore without issues like collapse, losses, or sticking. An optimal mud weight program aims for consistency while keeping equivalent circulation density and surge/swab pressures within limits. Both underbalanced and overbalanced mud weights are addressed, with the median line concept recommending a mud weight midway between fracture and pore pressures. Proper drilling hydraulics are also important for efficient hole cleaning and preventing problems.

![Mud weight vs. penetration rate

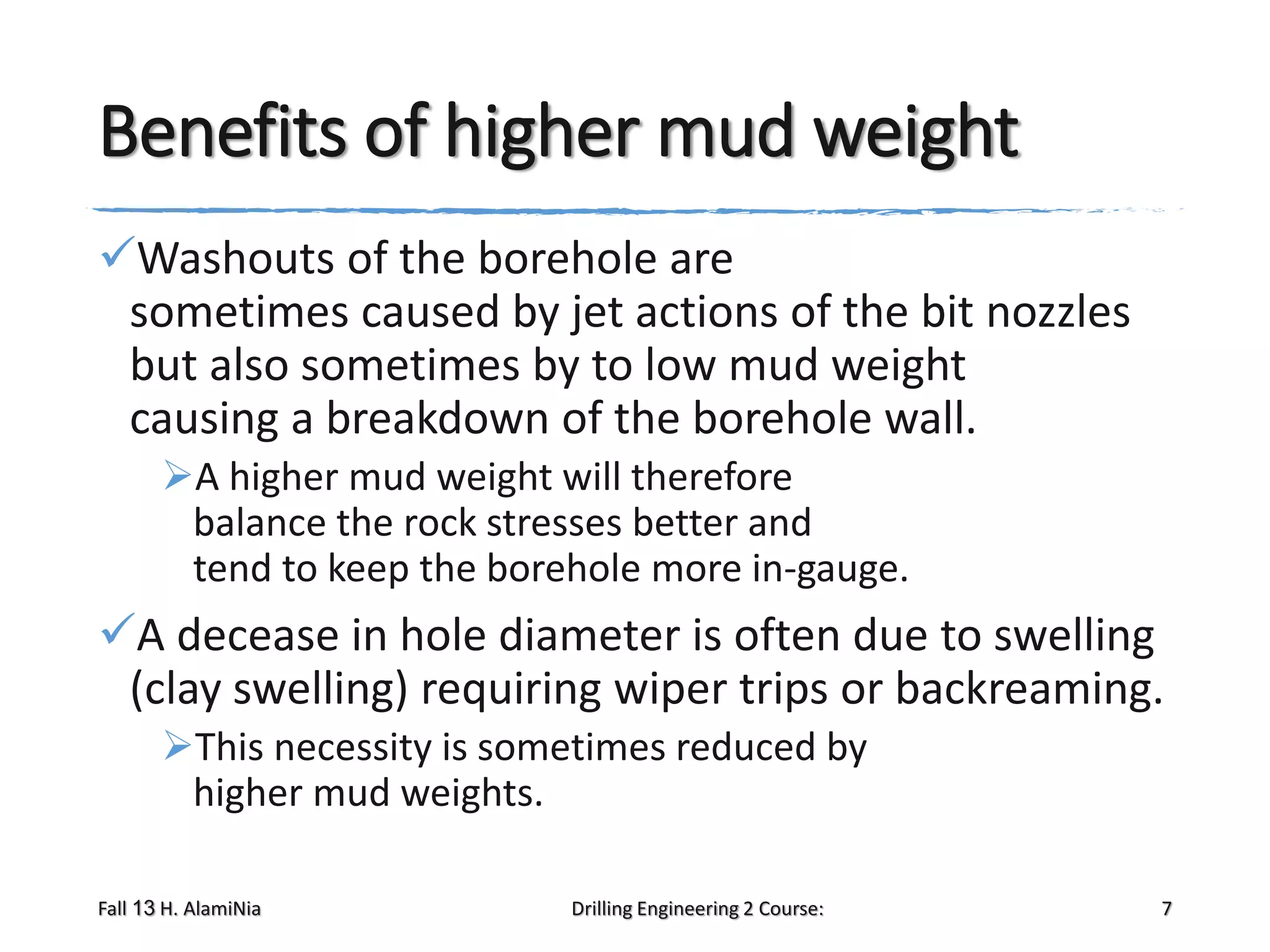

It is often argued that to have

a as high as possible rate of penetration,

the mud weight shall be kept as close as possible

to the formation pressure gradient

plus a safety margin of around 100 [psi].

Although it is true that a small reduction in mud weight

increases the penetration rate,

but this increases has to be weighted against the possible

induction of hole problems and additional lost time.

A higher mud weight requires the use of more mud

additives which makes the well more expensive,

but it was found that

these extra costs are usually neglectable.

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

11](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-11-2048.jpg)

![average horizontal in-situ stress

Mentioned principle is

mathematically found

with following

equation:

𝜎 𝑎 =

𝑃 𝑤𝑓 +𝑃 𝑜

2

𝜎 𝑎 [psi] average

horizontal in-situ stress,

Pwf [psi] fracture stress,

Po [psi] pore pressure

Pressure gradients for a well

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

15](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-15-2048.jpg)

![Changing mud weight

Experience had shown that

new drilling fluid exacerbates fracturing/lost circulation

and

leakoff tests applying used drilling muds give higher

leak-off values than when carried out with new ones.

Therefore it is a good practice that,

when the mud weight has to be changed

after setting casing,

drilling is usually started with a lower mud weight.

After drilling about 100 [m] below the casing shoe,

the mud weight is then gradually increased

to the desired value.

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

16](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-16-2048.jpg)

![Changing mud weight (Cont.)

Furthermore it should be noticed that

within an open-hole section,

the mud weight shall only be increased and

not decreased since tight hole may result.

An increase of mud weight in steps of 0.05 [g/cm3]

is good practice and in convenience of the mud

engineer.

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

17](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-17-2048.jpg)

![Hydrostatic Pressure

Inside the Wellbore

Hydrostatic definition:

relating to or denoting the equilibrium of liquids and

the pressure exerted by liquid at rest.

For oil well applications, the fluid may be

mud, foam, mist, air or natural gas.

For a complex fluid column consisting of multiple

fluids, the hydrostatic pressure is given in field units

by:

𝜌

𝑚𝑖

Fall 13 H. AlamiNia

[ppg] mud weight of the ith fluid column

Drilling Engineering 2 Course:

22](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-22-2048.jpg)

![barometric formula

When gas is present in the well, the hydrostatic

pressure developed by the gas column is calculated

with:

z [1] ... real gas deviation factor

po [psi] ... surface pressure

D [ft] ... total depth (TVD)

Tf [F] ... bottom hole temperature of the formation

The molecular weight M of the gas is found as:

• where:

o 𝜌 𝑔 [ppg] ... density of the gas

o T [F] ... average gas density

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

23](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-23-2048.jpg)

![equivalent mud weight

For practical purposes, the hydrostatics due to a

complex fluid column are converted to an

equivalent single-fluid hydrostatic pressure.

To do this,

all individual hydrostatic pressures are summed up for a

specific depth pd and

then converted to an equivalent mud weight 𝜌 𝑒 [ppg]

that would cause the same hydrostatic pressure.

Therefore the equivalent mud weight

has to be always referenced to a specific depth.

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

24](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-24-2048.jpg)

![average mud weight

As the mud is used to transport the cuttings from

the bottom of the hole to the surface and

penetrated formations often contain a certain

amount of formation gas, the mud column at the

annulus is usually mixed with solids and gas.

This alters the weight of the mud at the annulus.

The new average mud weight m of a mixture containing

mud and solids can be calculated as:

mi [lbm] mass of component i

Vi [gal] volume of component i

𝜌 𝑖 [ppg] density of component i

fi [1] volume fraction of component i

Fall 13 H. AlamiNia

Drilling Engineering 2 Course:

25](https://image.slidesharecdn.com/q921-de2-20lec3-20v1-131107195152-phpapp01/75/Q921-de2-lec3-v1-25-2048.jpg)