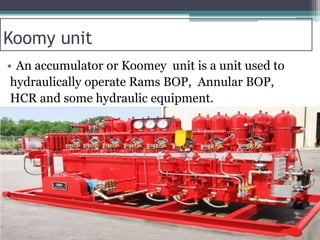

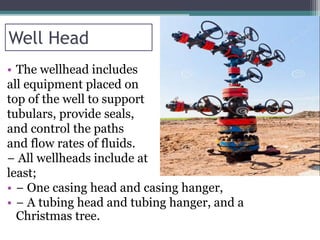

This document discusses well control equipment used in drilling operations. It describes blowout preventers (BOPs) which are used to close the well and control kicks before they become blowouts. There are different types of BOPs including annular preventers, ram preventers, and rotational preventers. Other important well control equipment includes an accumulator unit to operate BOPs hydraulically, inside BOPs, choke and kill lines, and a wellhead with casing heads to support tubulars and control fluid flow. Components should be function tested at least weekly to verify operations and actuation times should be recorded.