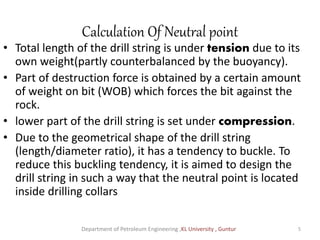

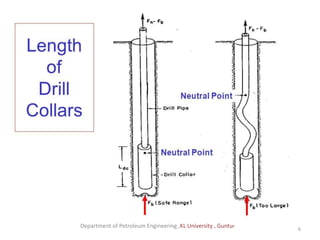

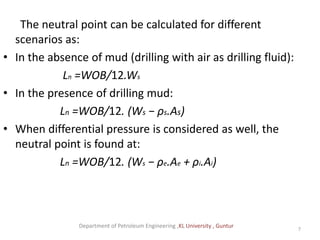

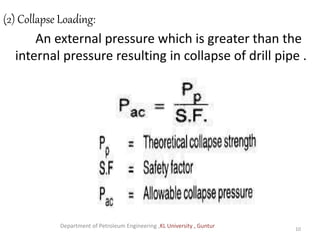

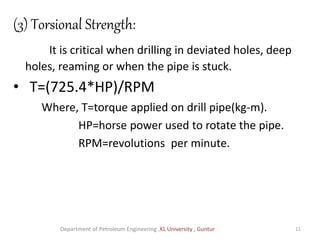

The document discusses the components and functions of a drill string. It describes the main components as the kelly, drill pipe, drill collars, and drilling bit. It explains the drill string provides functions like imposing weight on the bit, transmitting rotation, providing a fluid conduit, and allowing tools to be run in the hole. It also discusses calculating the neutral point where there is no compression or tension in the pipe, using factors like weight on bit, pipe weight, mud density, and differential pressure. The document concludes by covering selection considerations for drill pipes based on tension loading, collapse resistance, and torsional strength needed for deviated holes.