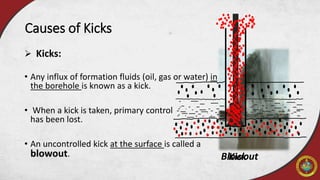

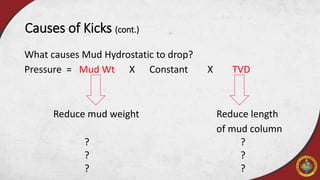

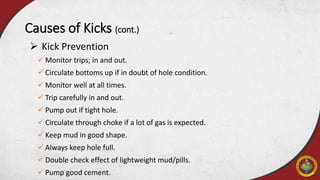

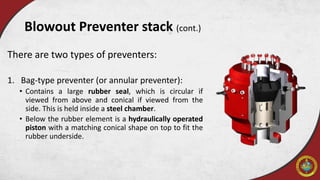

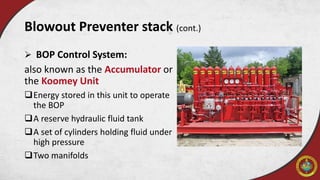

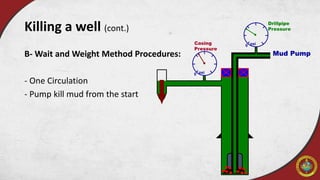

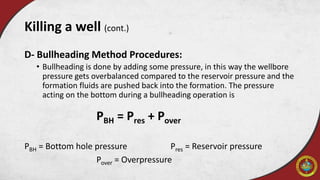

This document provides an overview of well control procedures. It discusses causes of kicks such as swabbing or pumping light mud that can lead to underbalance. Primary well control relies on mud hydrostatic pressure, while secondary control uses a blowout preventer. Tertiary control involves pumping substances to stop downhole flow. Methods for killing a well are also presented, including the driller's method, wait and weight, volumetric, and bullheading. Kick detection equipment like the pit volume totalizer and flow indicator are also outlined.