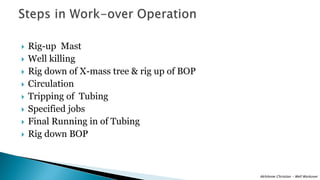

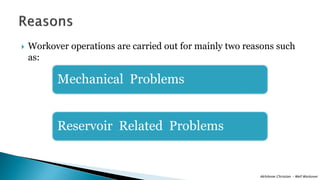

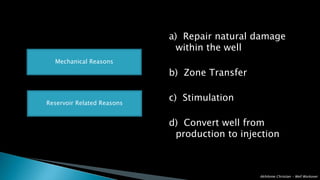

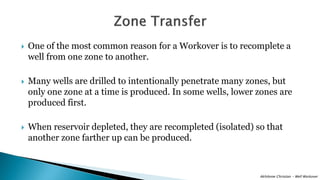

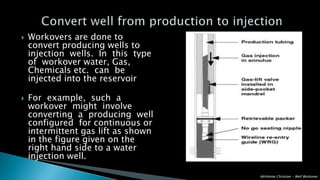

The document discusses workover operations in oil and gas wells, which are conducted to enhance well performance through various interventions such as well killing, recompletion, and installation of down-hole production equipment. It highlights the reasons for workovers, including mechanical and reservoir-related issues, as well as the importance of maintaining the well to optimize its profitability and output. Techniques like stimulation and artificial lift are also mentioned as part of the overall workover process.