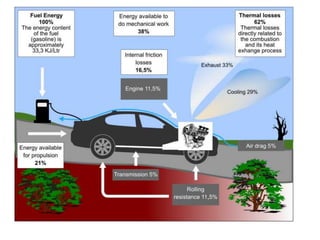

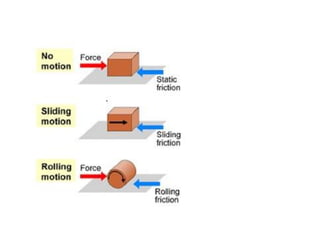

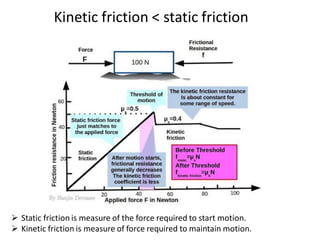

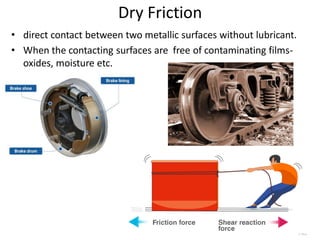

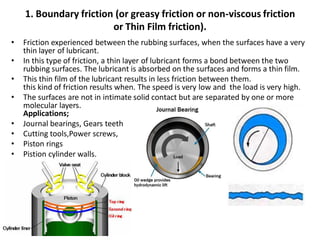

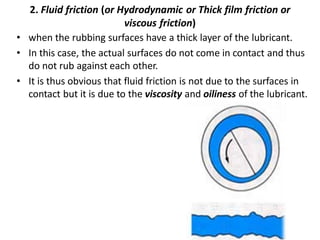

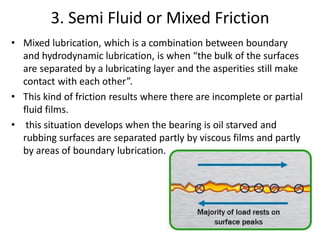

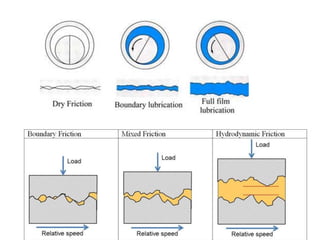

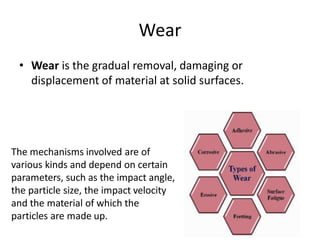

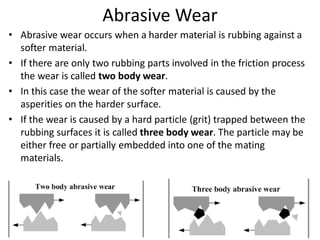

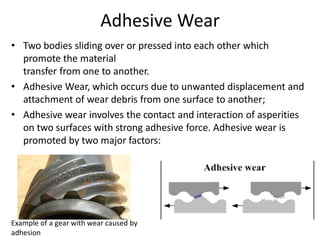

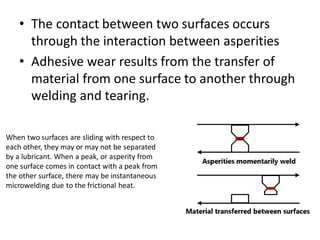

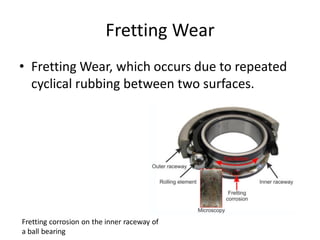

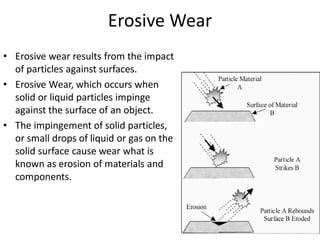

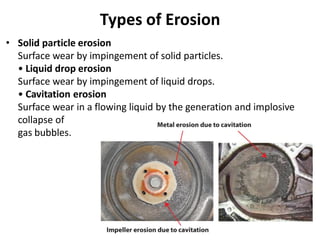

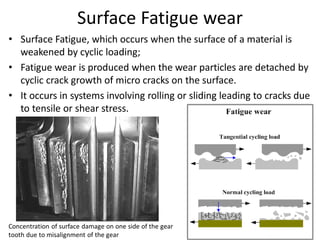

The document discusses the significant impact of friction on energy consumption in mechanical systems, highlighting types of friction such as static, dynamic, sliding, and rolling friction. It distinguishes between unlubricated and lubricated friction, exploring the effects of boundary, fluid, and mixed lubrication. Additionally, the document outlines various wear mechanisms including abrasive, adhesive, fretting, erosive, surface fatigue, and corrosive wear, emphasizing their causes and consequences in machinery.