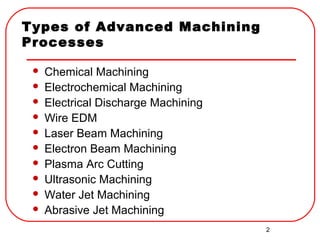

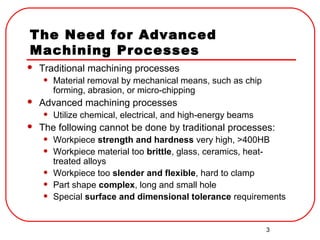

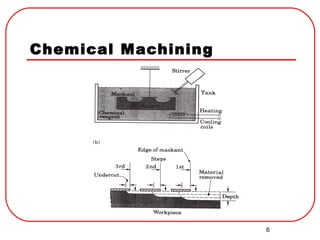

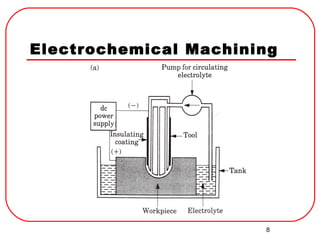

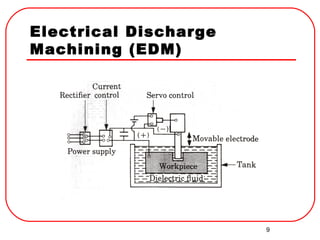

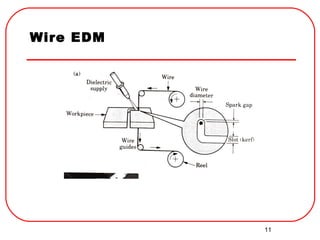

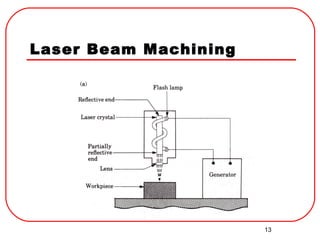

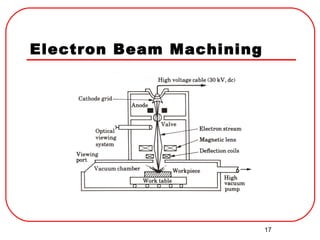

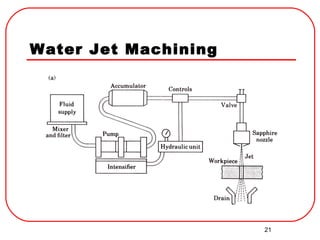

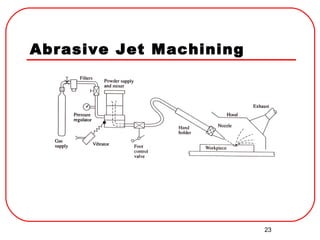

This document discusses advanced machining processes, which utilize chemical, electrical, or high-energy beams to machine materials that cannot be processed through traditional machining methods. It describes 10 common types of advanced machining, including chemical machining, electrochemical machining, electrical discharge machining, laser beam machining, electron beam machining, plasma arc cutting, ultrasonic machining, water jet machining, abrasive jet machining, and nanofabrication methods. The document explains the need for these advanced processes and provides examples of typical parts machined through these methods.