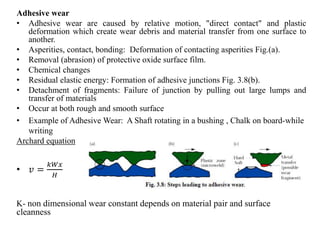

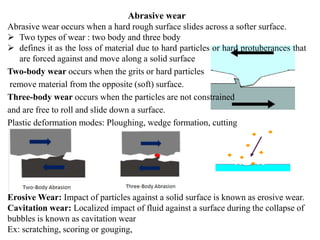

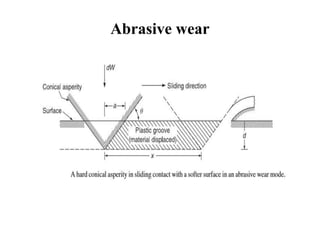

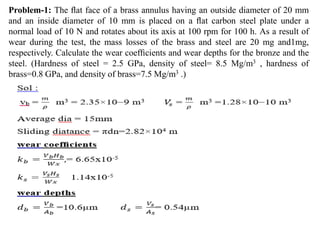

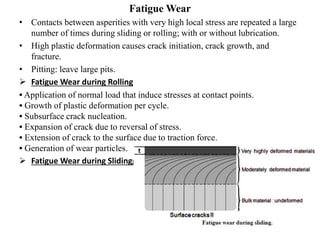

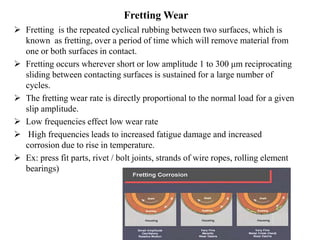

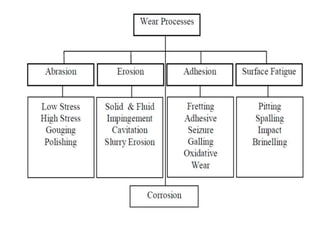

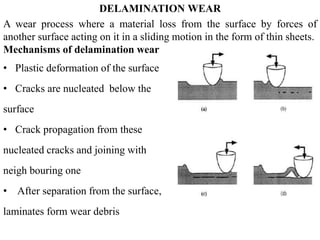

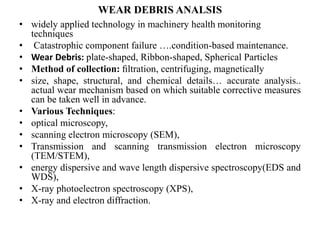

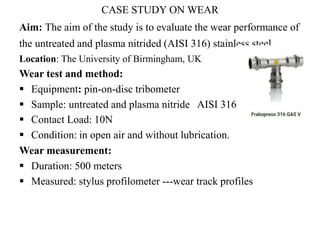

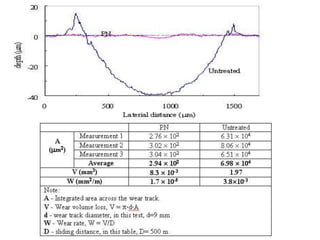

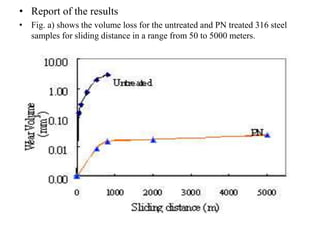

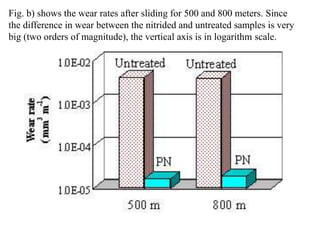

Wear occurs due to the surface damage or removal of material from two solid surfaces in relative motion. It can occur through various mechanisms including abrasive, adhesive, corrosive, fatigue, and fretting wear. A case study evaluated the wear performance of untreated and plasma nitrided AISI 316 stainless steel using a pin-on-disc tribometer under a 10N load in open air. The plasma nitriding reduced the wear rate by over 200 times due to a change in wear mechanism from abrasive to oxidative wear. Analysis of wear debris and tracks provides insights into the wear mechanisms and failure modes occurring.