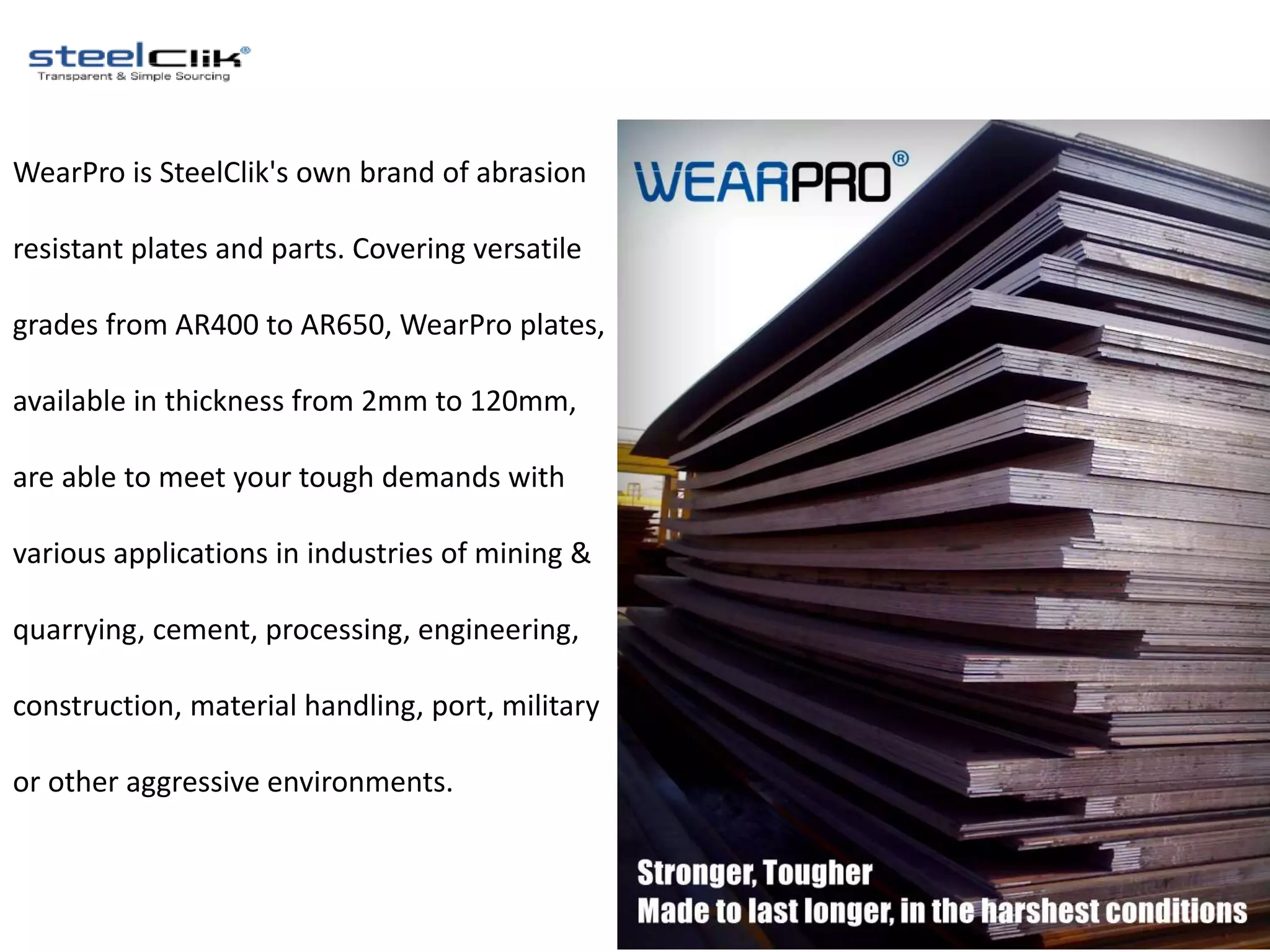

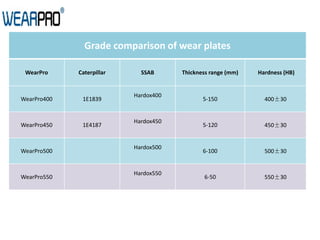

WearPro is SteelClik's brand of abrasion resistant steel plates available in thicknesses from 2mm to 120mm and grades from AR400 to AR650. These plates are suitable for applications in industries like mining, construction, and material handling due to their ability to withstand tough conditions without deforming or cracking. WearPro plates offer extended service life through their unique hardness and toughness. Their weldability and bendability also allow for innovative steel structure and component designs that improve payload and efficiency while lowering costs. SteelClik ensures consistent properties and quality in WearPro plates through careful material selection and heat treatment processes.