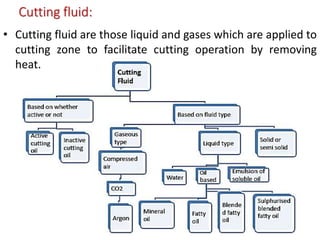

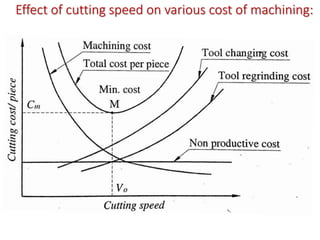

- The document discusses heat generation in machining and its effects, temperature measurement techniques, types and functions of cutting fluids, and economics of metal cutting operations.

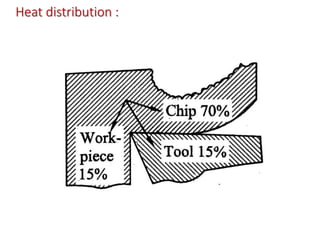

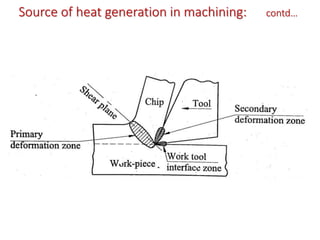

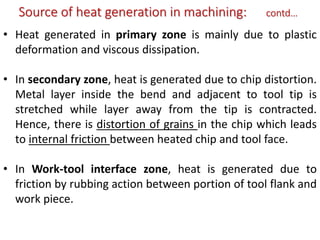

- Heat is generated in three zones during machining: the primary deformation zone, tool-chip interface, and tool-workpiece interface. Heat depends on factors like material properties and cutting parameters.

- High temperatures can damage tools and workpieces. Cutting fluids help reduce temperatures by conduction and convection of heat away from the cutting zone.

- Temperature is commonly measured using tool-workpiece thermocouples, which generate electrical signals related to temperature at the cutting interface.

![Measurement of chip-tool interface temp. contd…

• Tool and work material as two elements of thermocouple.

• The hot junction is contact area at the cutting edge.

• Cold part of tool forms cold junction.

[Tool-work thermocouple]](https://image.slidesharecdn.com/2thermalaspectsinmachining-181227105341/85/Thermal-aspects-in-machining-13-320.jpg)

![Measurement of chip-tool interface temp. contd…

• The thermoelectric emf [electromotive force] generated

between the tool and work piece during metal cutting is

measured using sensitive milli-voltmeter.

• These emf readings are converted in terms of temperature.](https://image.slidesharecdn.com/2thermalaspectsinmachining-181227105341/85/Thermal-aspects-in-machining-14-320.jpg)