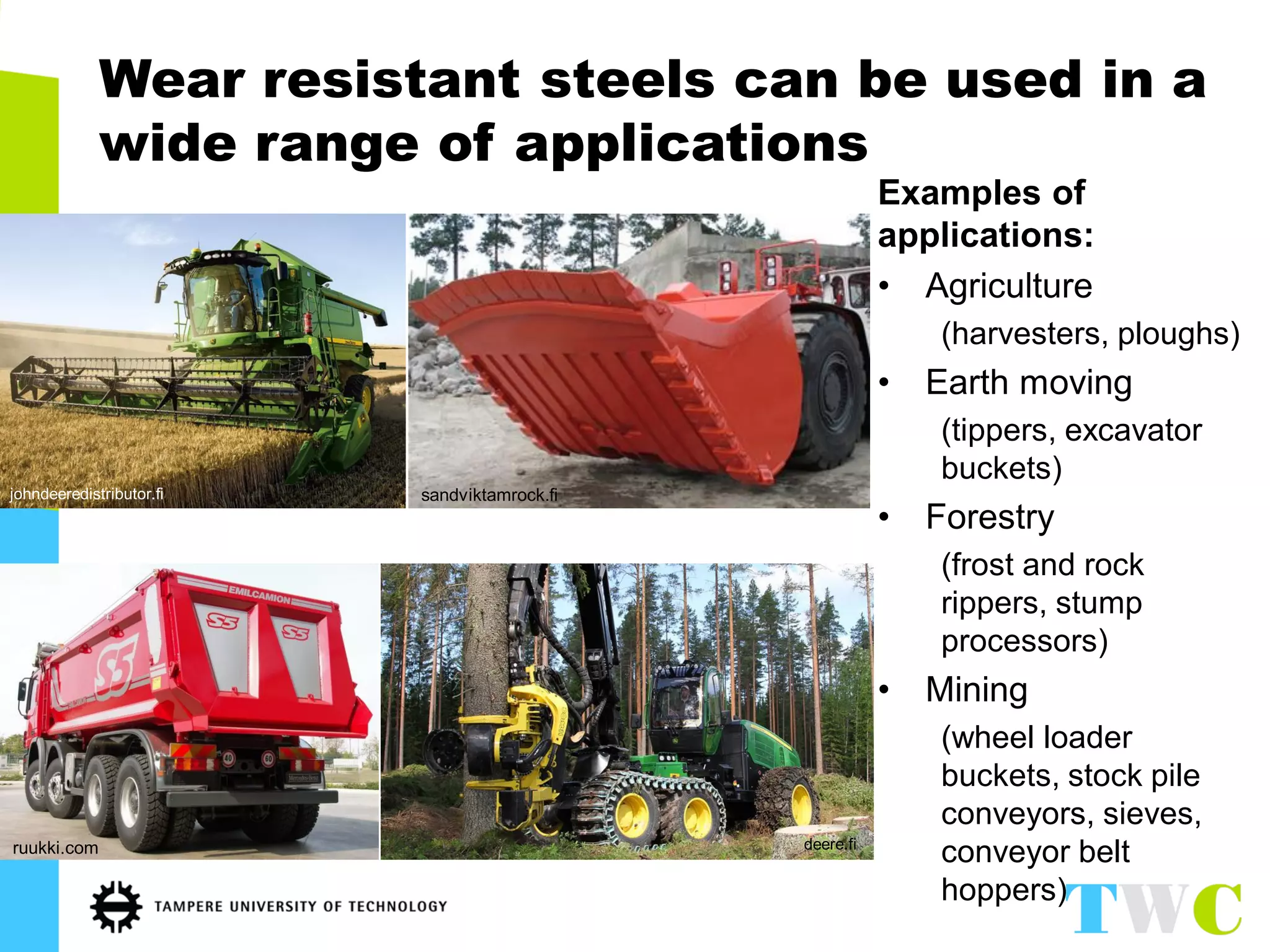

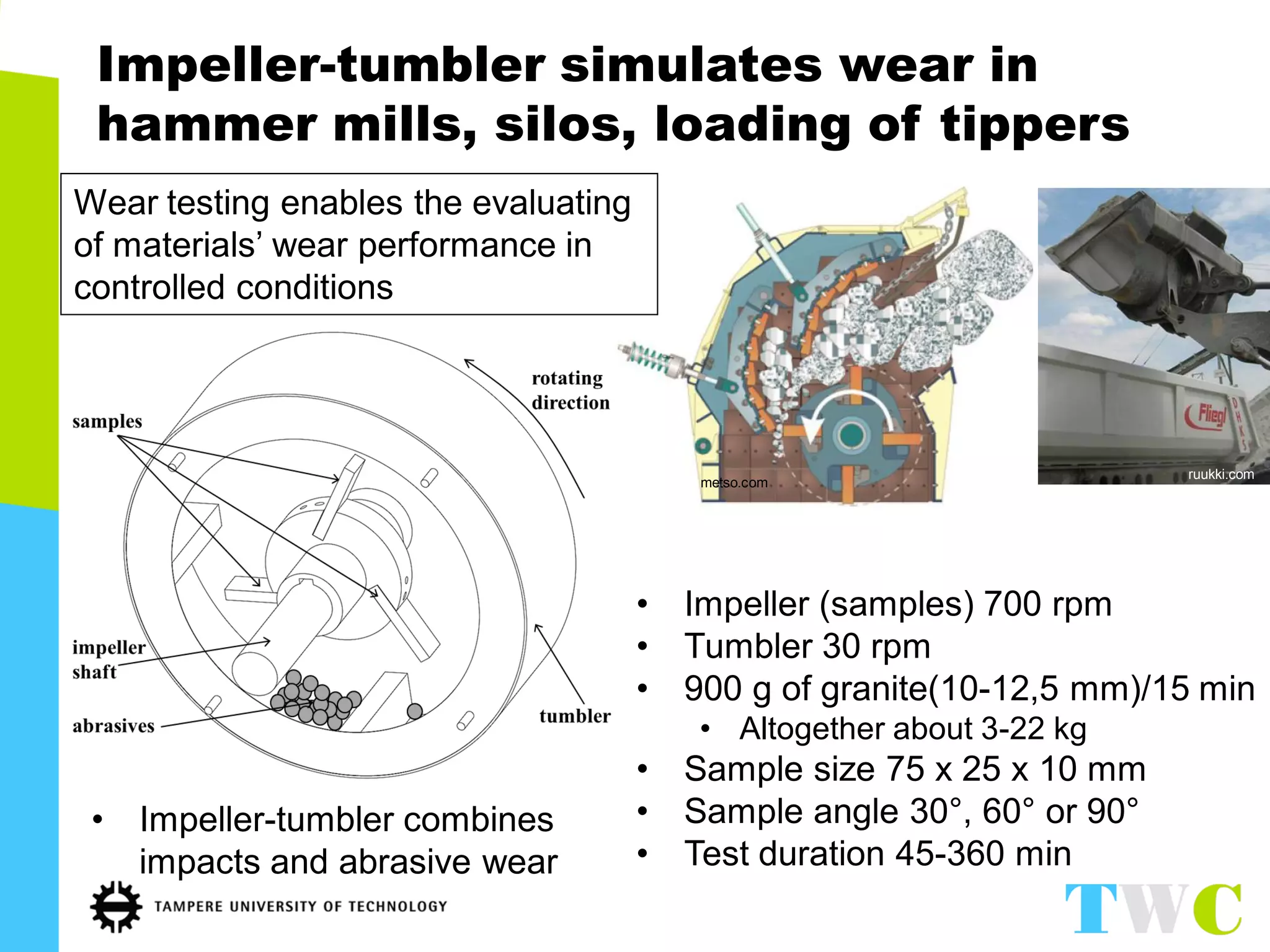

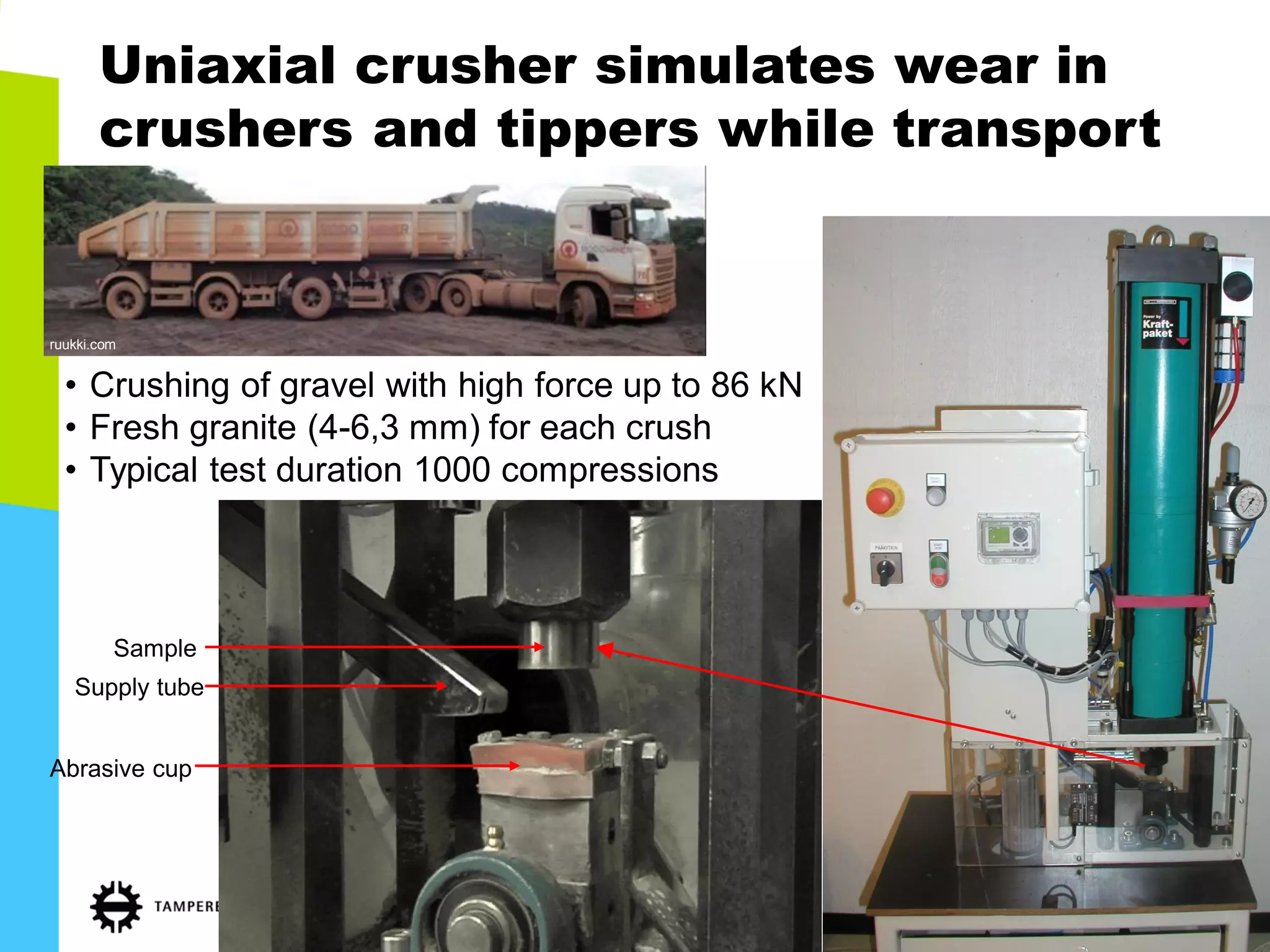

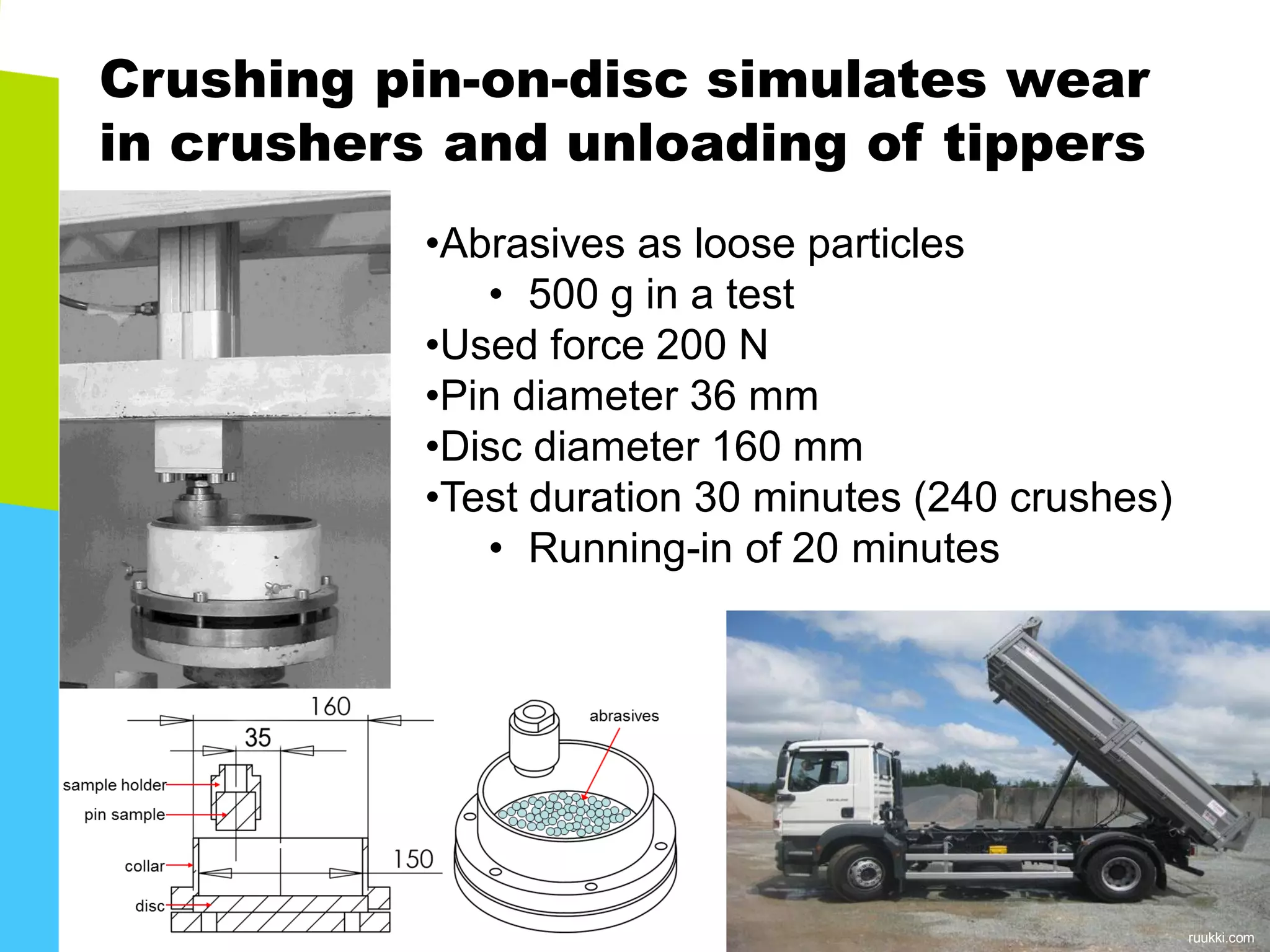

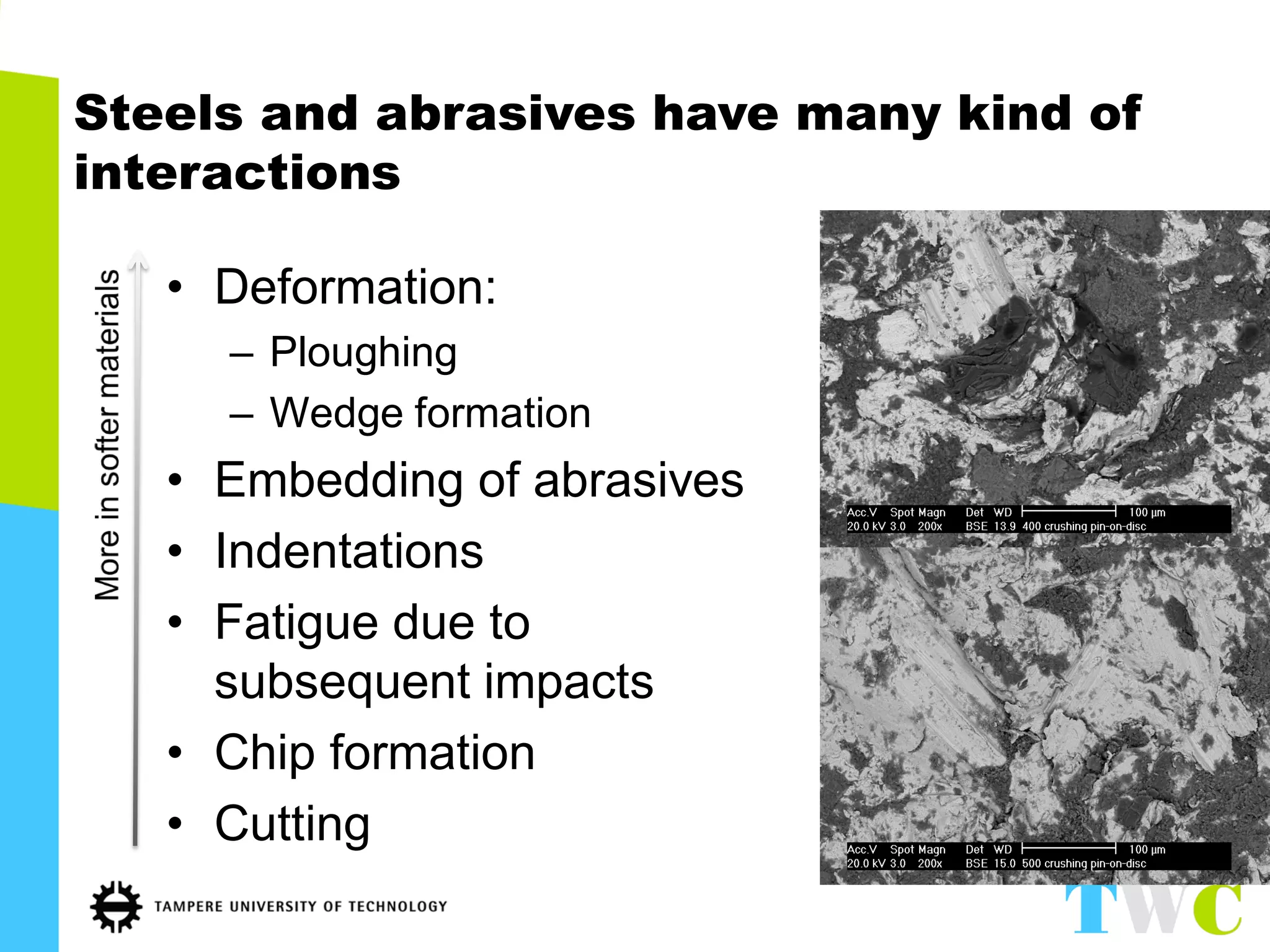

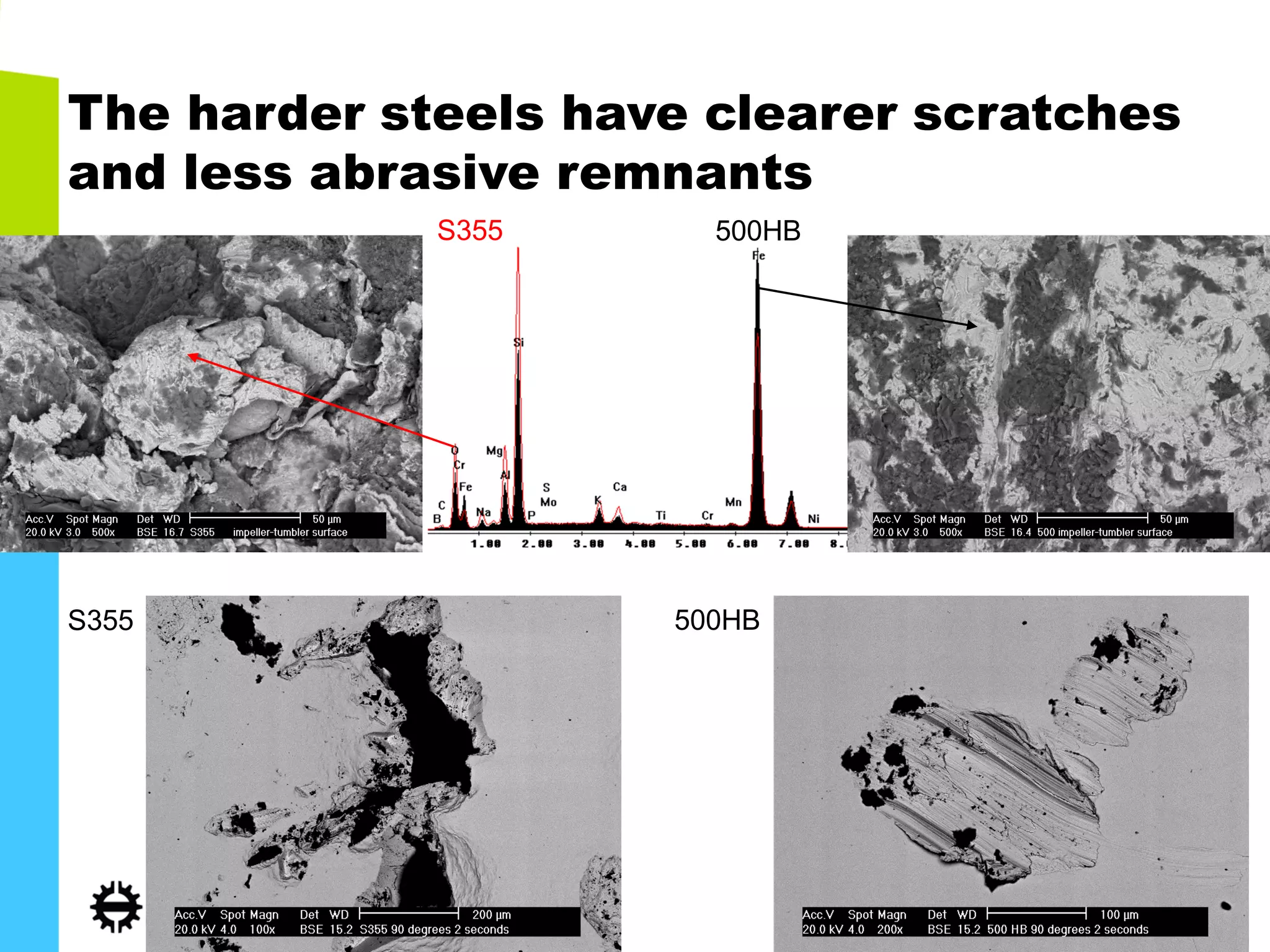

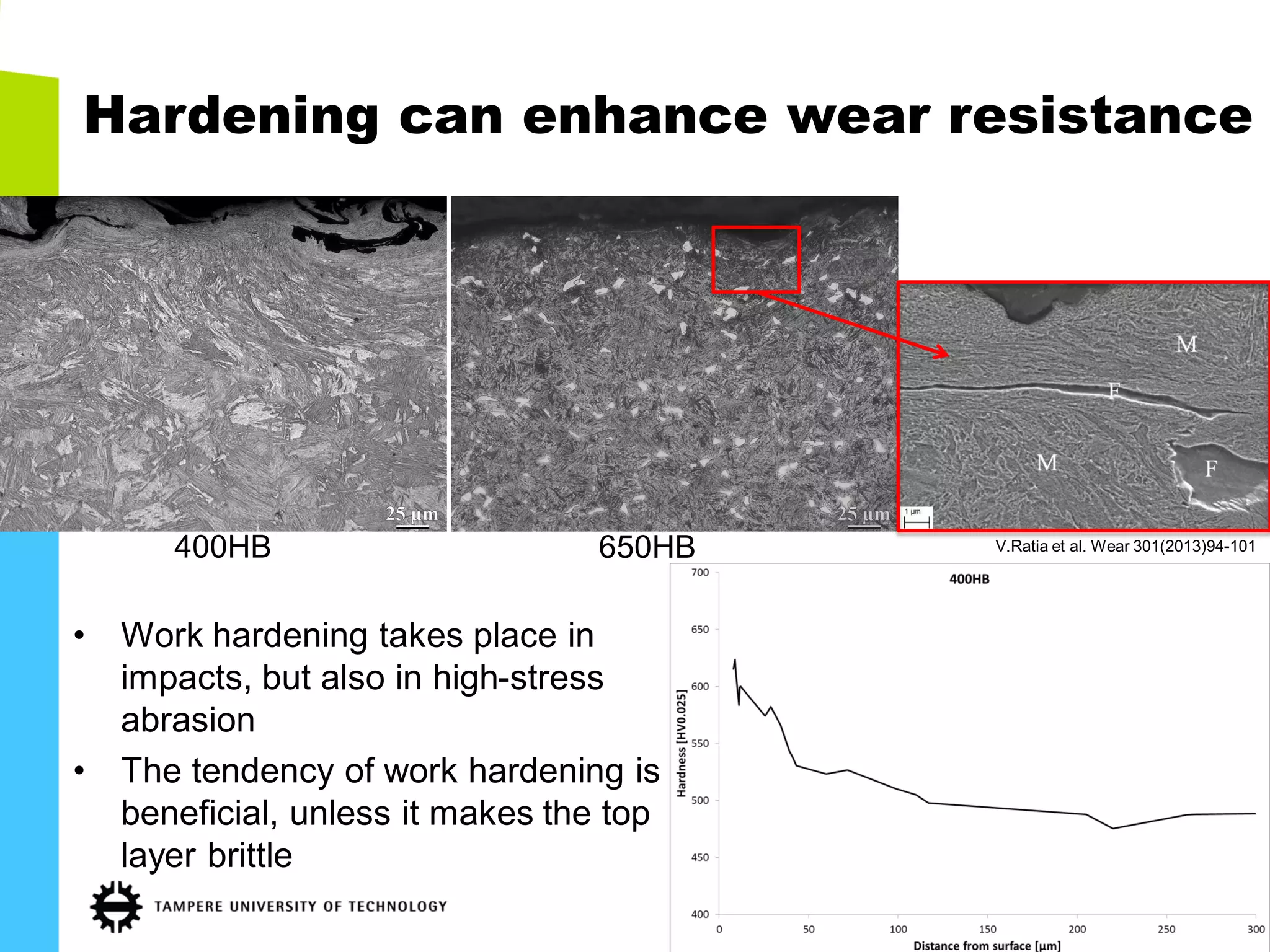

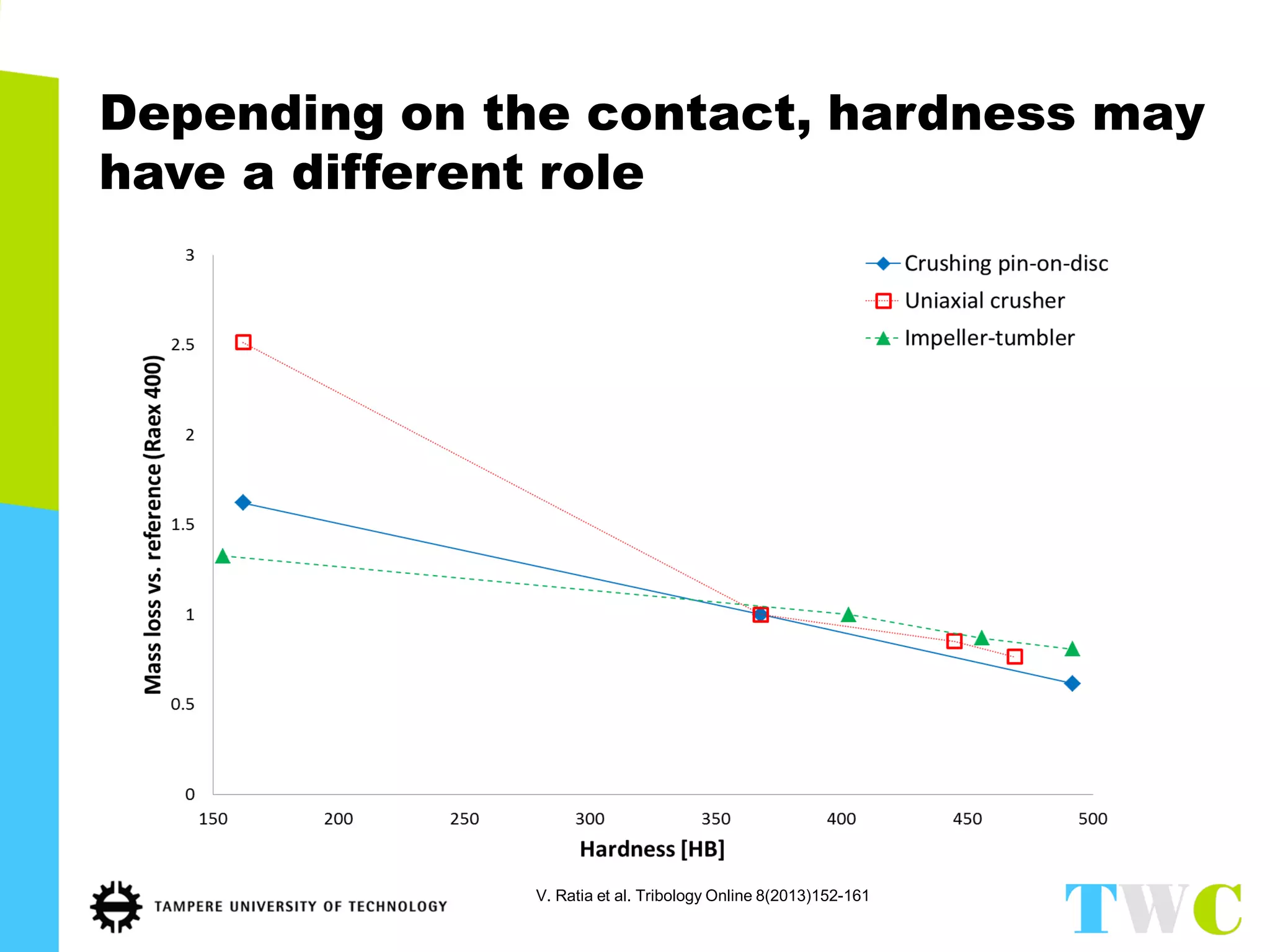

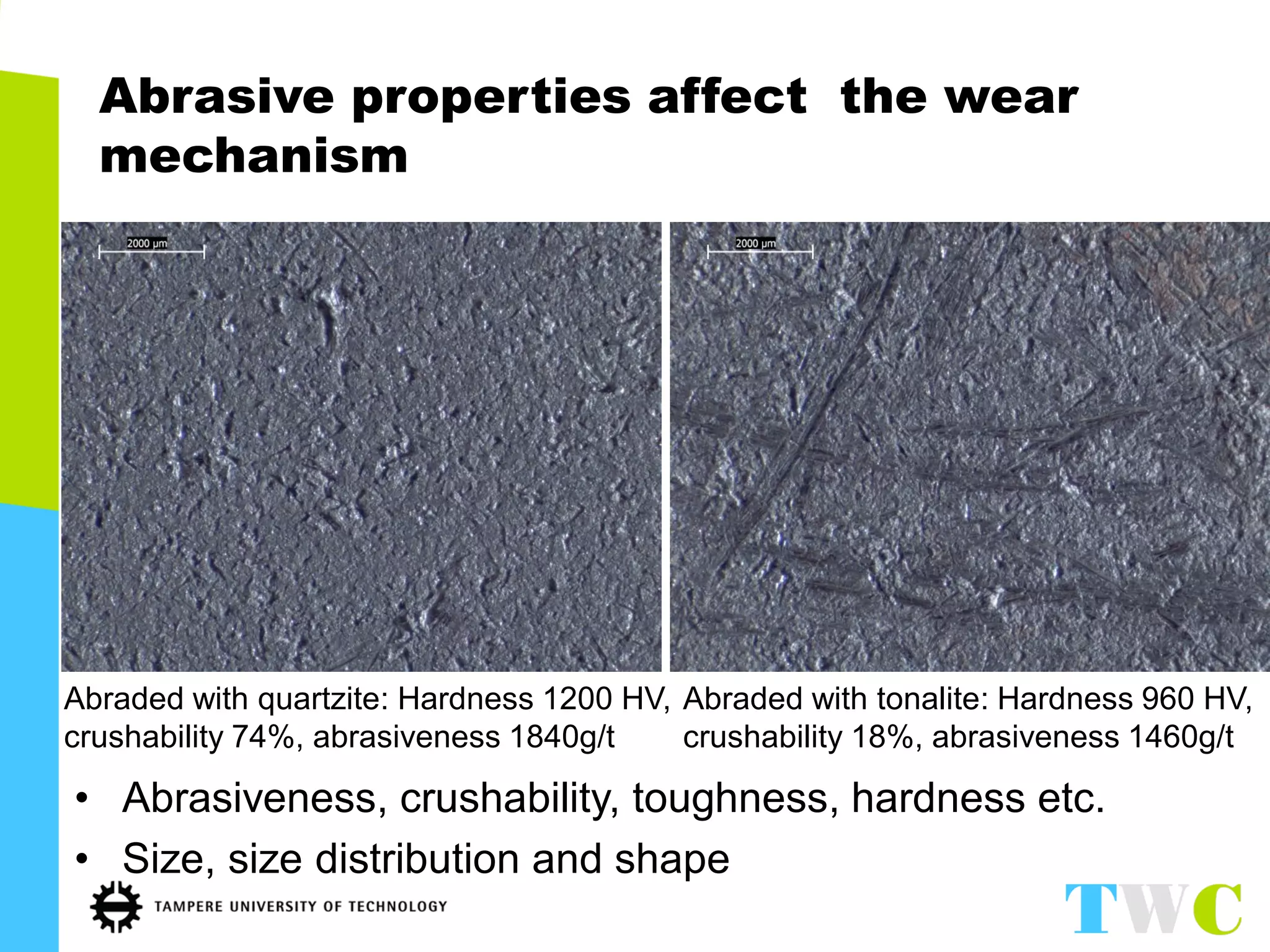

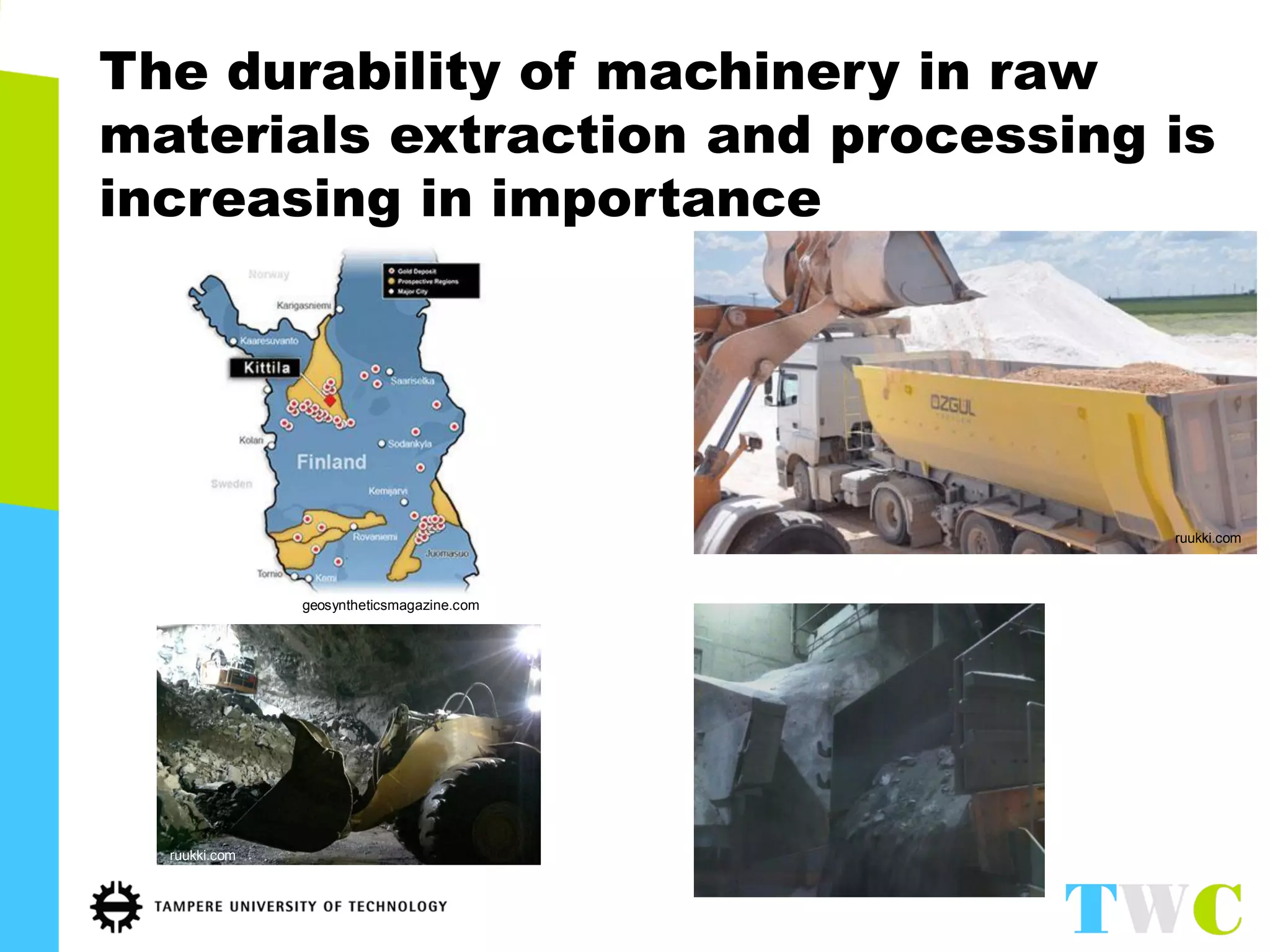

The document discusses abrasive and impact-abrasive wear testing of wear-resistant steels used in mining and mineral processing. It details the properties of these steels, such as higher strength and hardness compared to conventional steels, and highlights various applications in industries like agriculture and forestry. The wear testing methodologies described include an impeller-tumbler and uniaxial crusher to evaluate material performance under controlled conditions.

![0.142

0.158

0.163

0.165

0.172

0.173

0.176

0.180

0.186

0.189

0.192

0.199

0.202

0.208

0.216

0

100

200

300

400

500

600

700

800

900

1000

0.000

0.050

0.100

0.150

0.200

0.250

0 2 15 4 14 3 10 11 5 24 18 17 6 16 1

Surface hardness [HV5]

Mass loss [g]

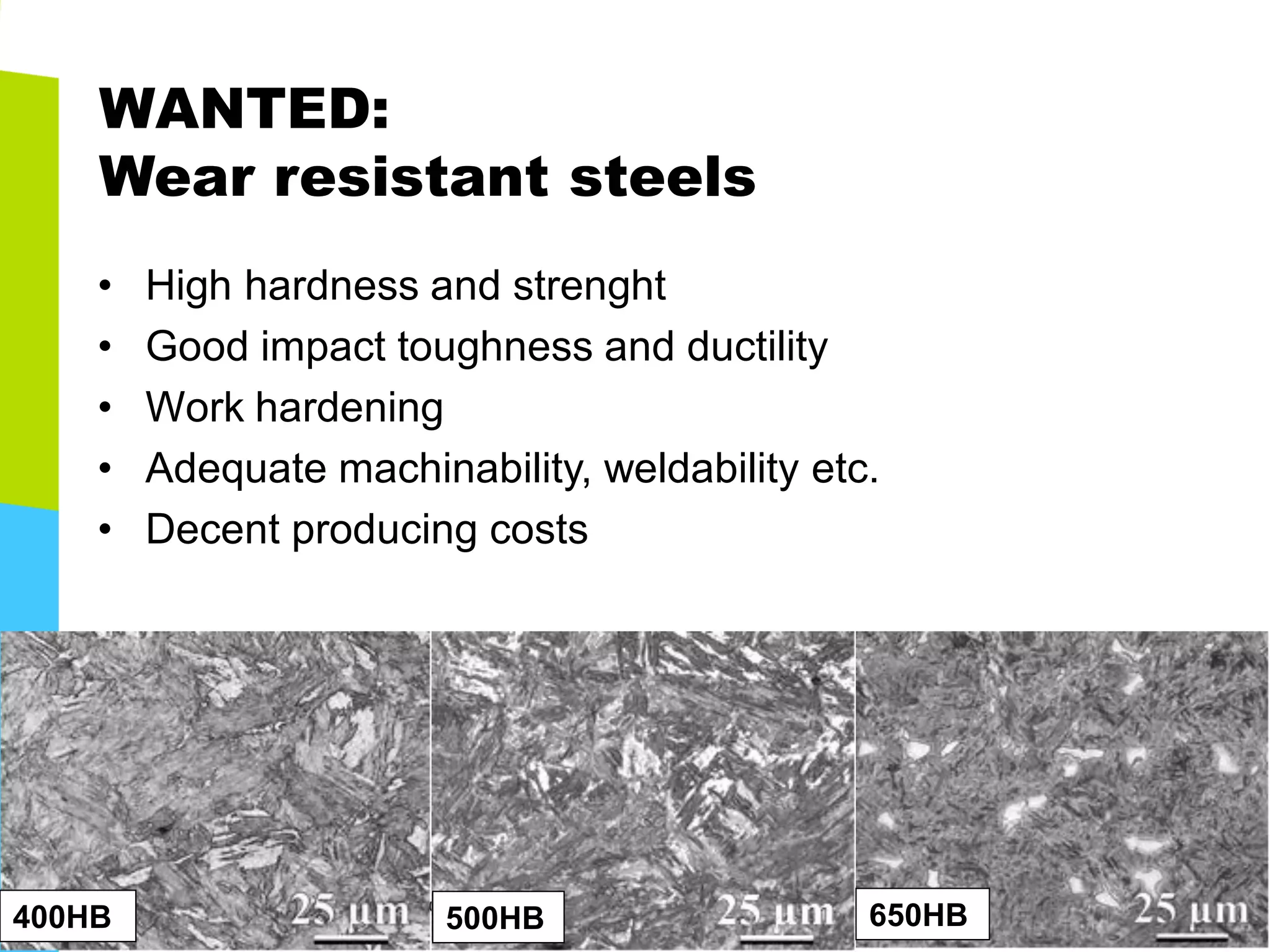

Wear resistant steels have higher

strength and hardness than

conventional structural steels

• Commonly graded

according to hardness

in Brinell scale:

400HB, 500HB, 600HB

• Tensile strength

typically 1200-1600

MPa

• Notch impact energy at

-40C typically 30 J/cm2

• Microstructure often

martensitic, but bainite,

ferrite, pearlite and

austenite are also

possible

ruukki.com

N. Ojala et al. WTC 2013 & Wear 317(2014)225-232](https://image.slidesharecdn.com/hardrocktribpresentationslideshare-141126083059-conversion-gate01/75/Abrasive-and-impact-abrasive-wear-testing-of-steels-for-mining-transporting-and-minerals-processing-4-2048.jpg)