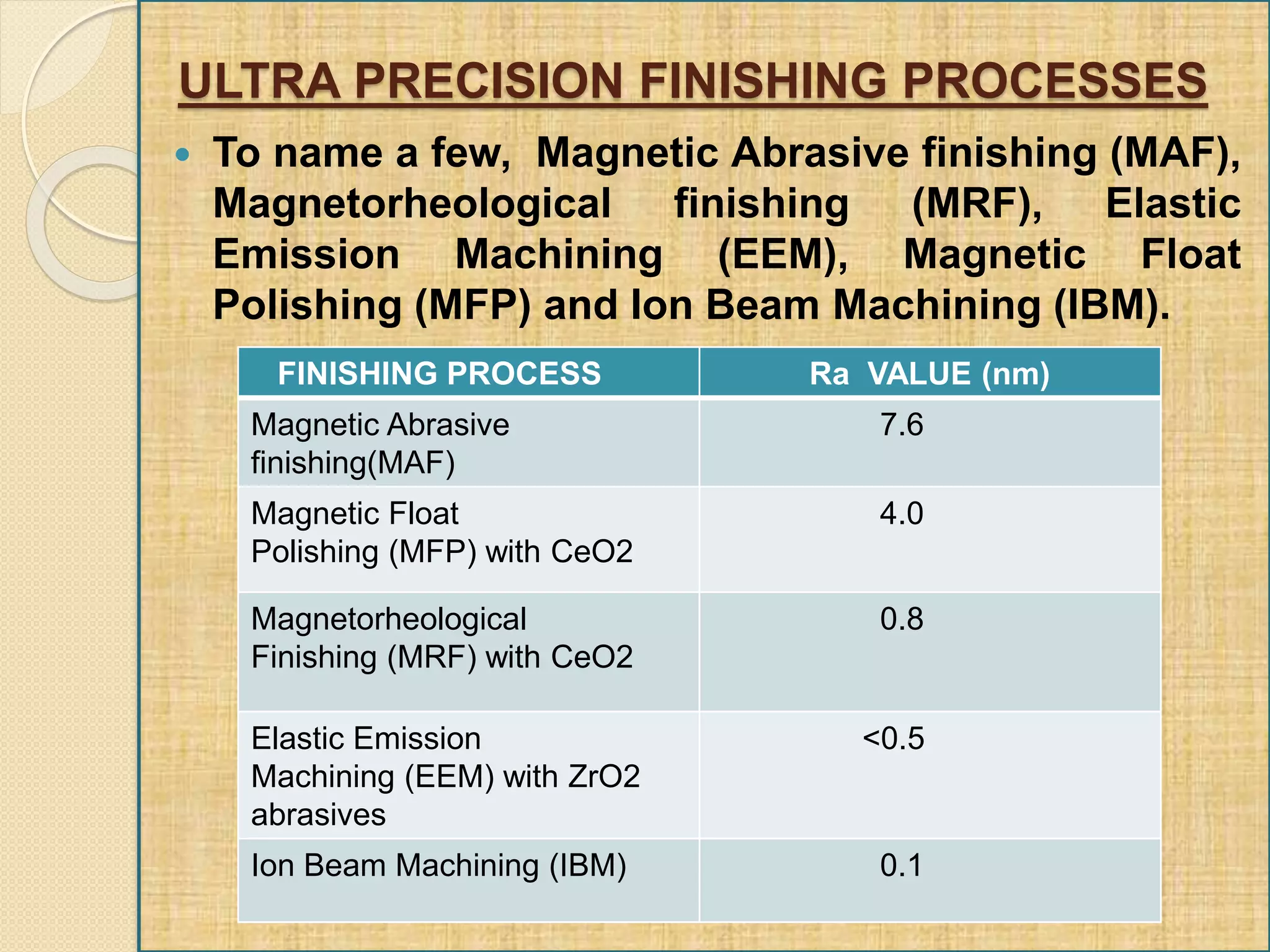

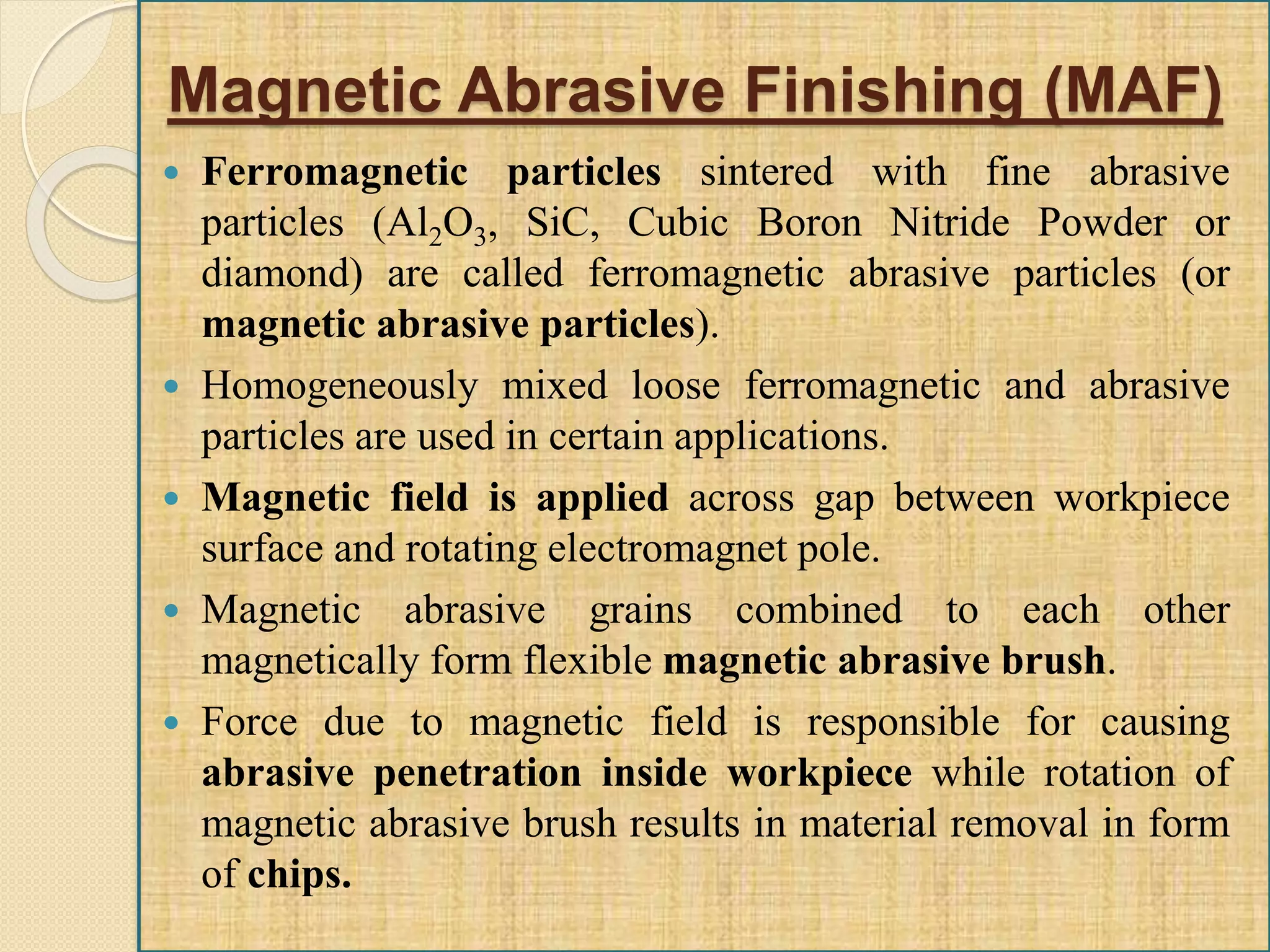

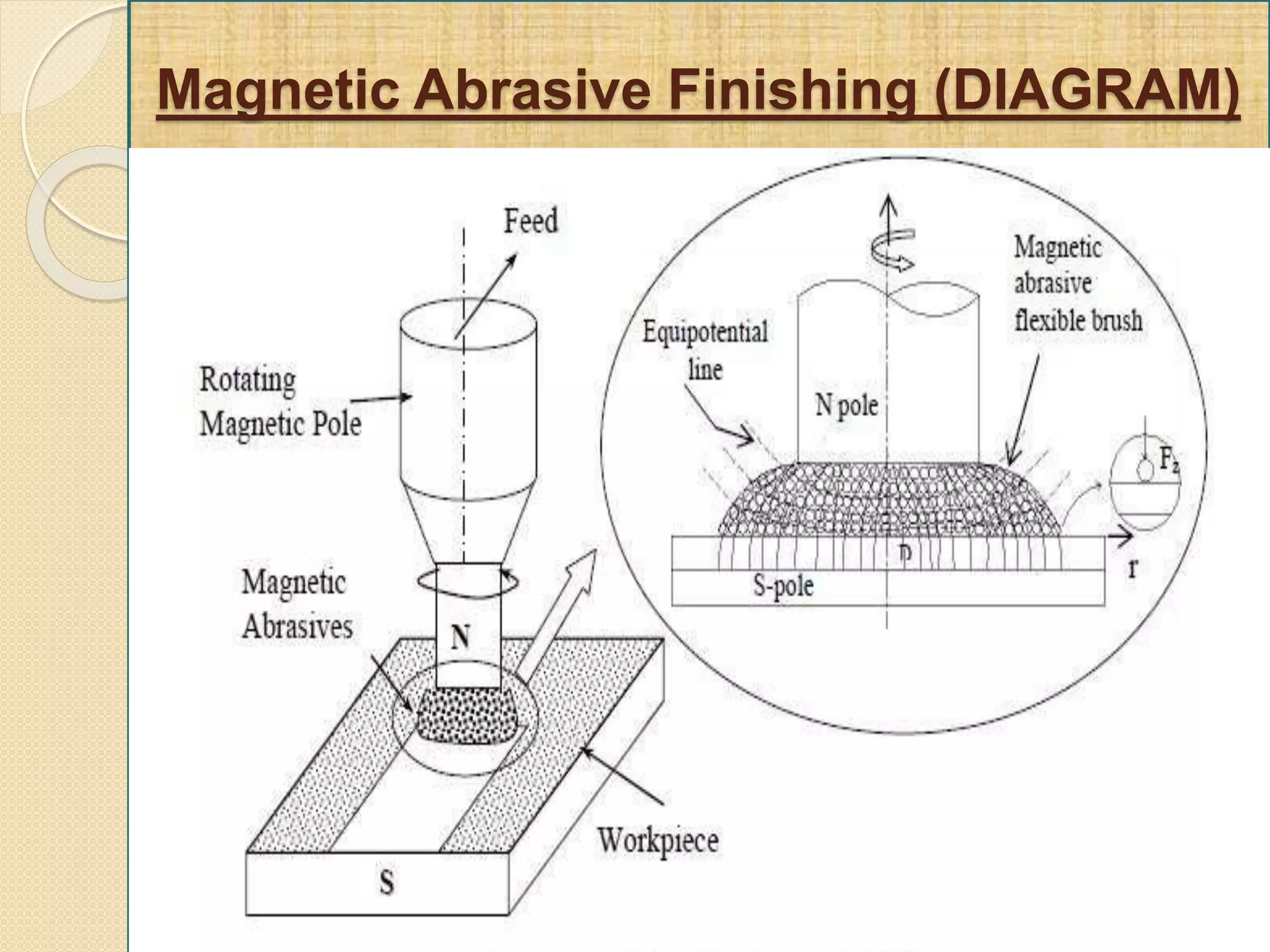

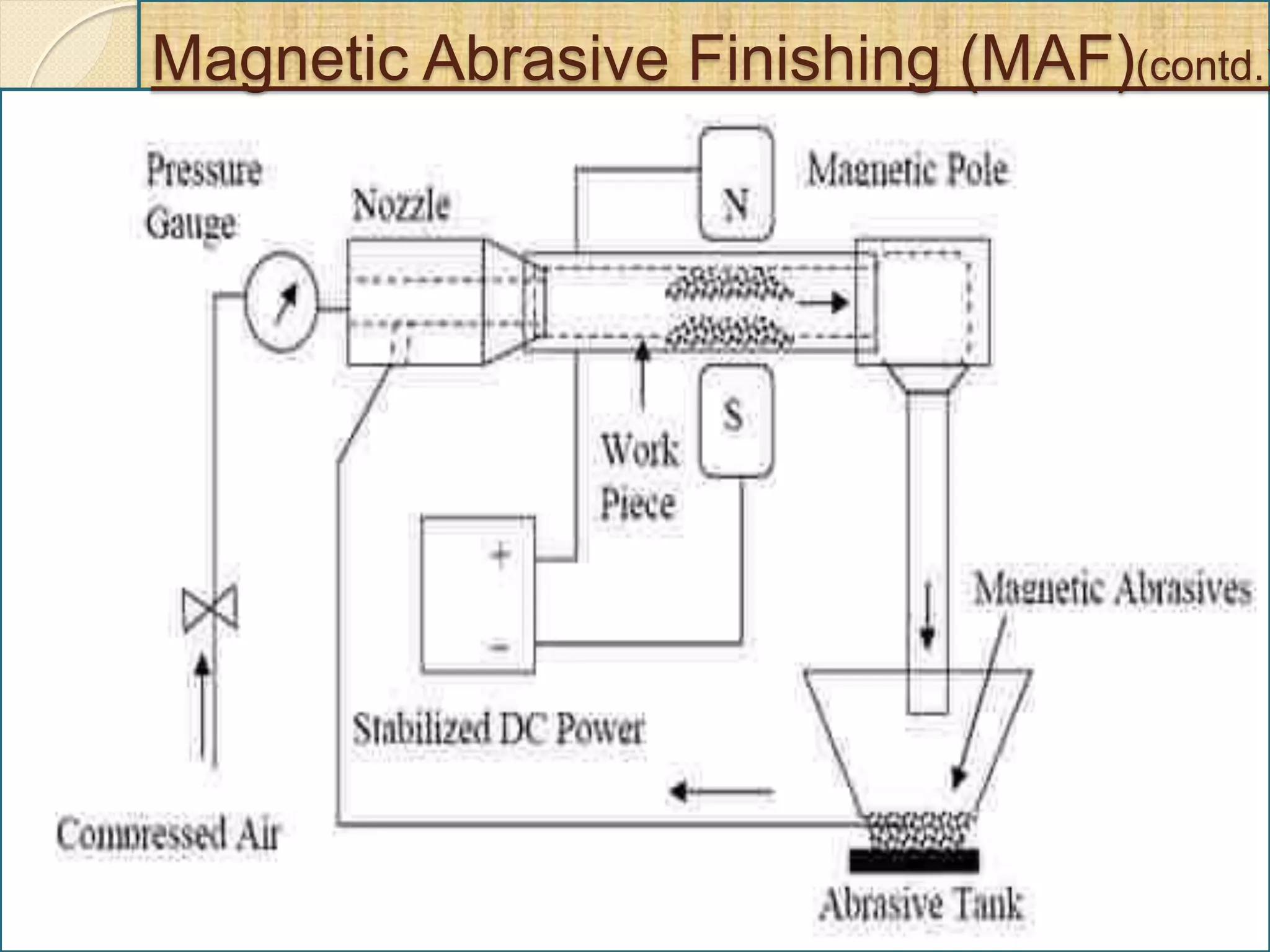

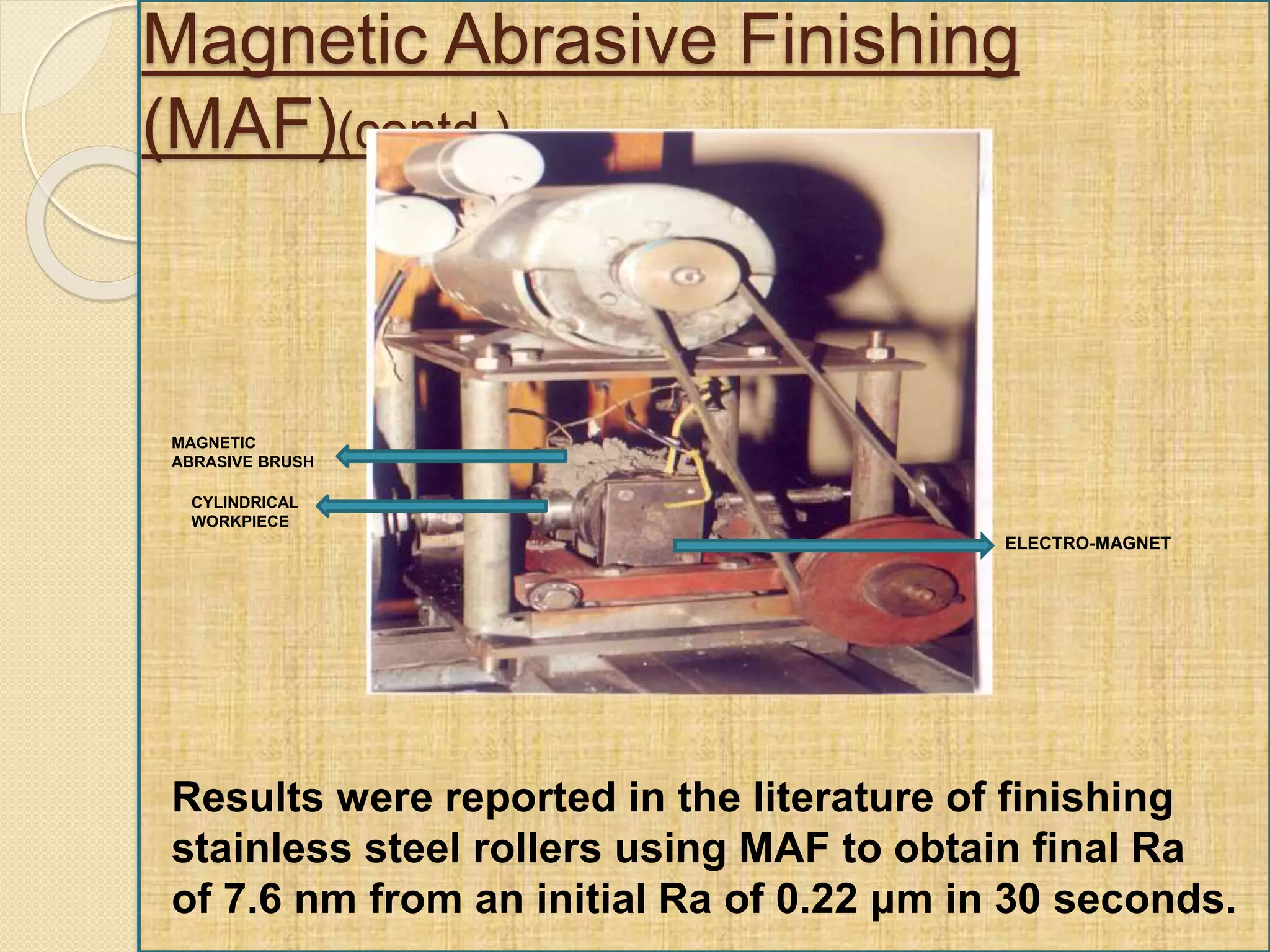

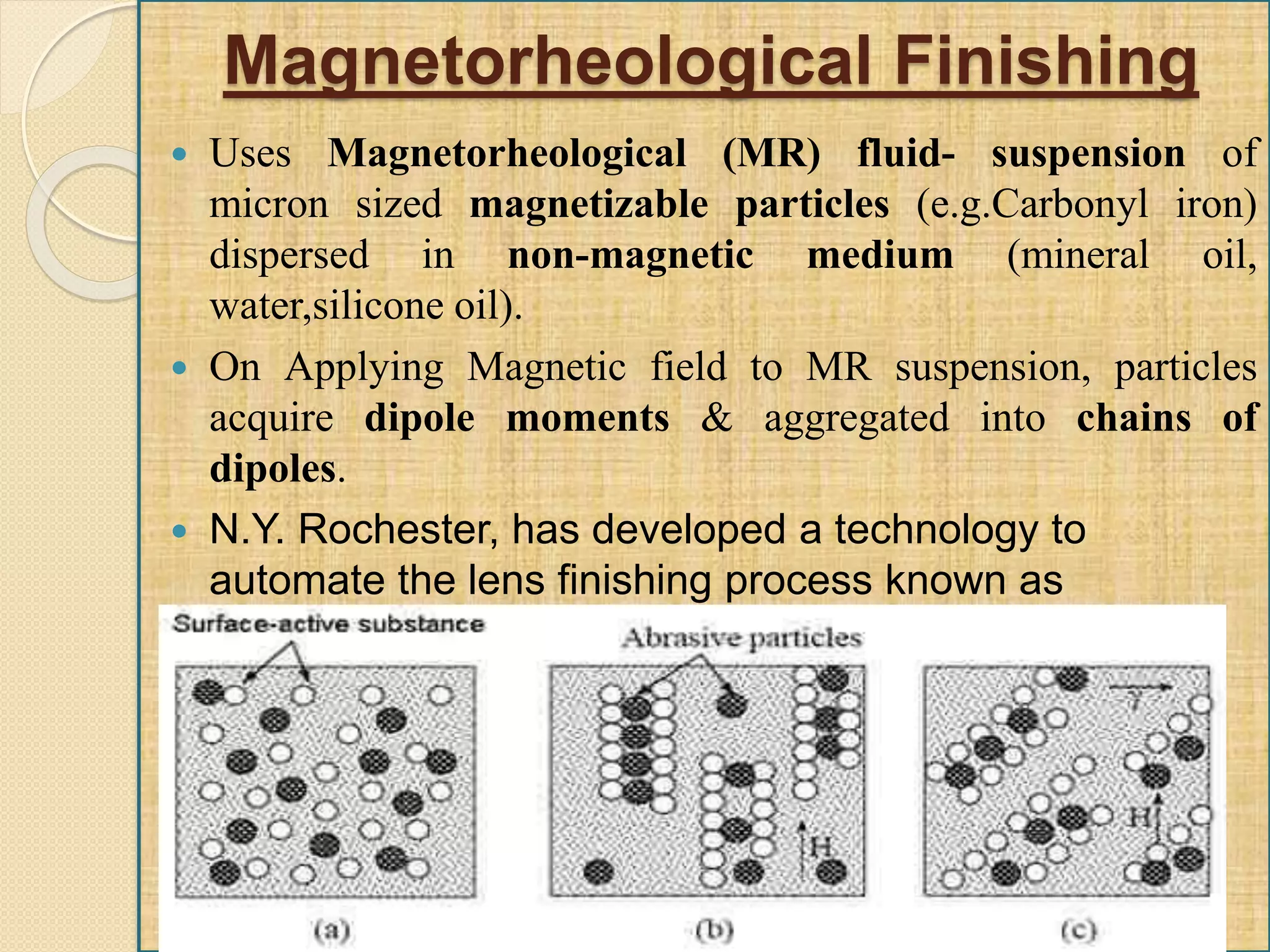

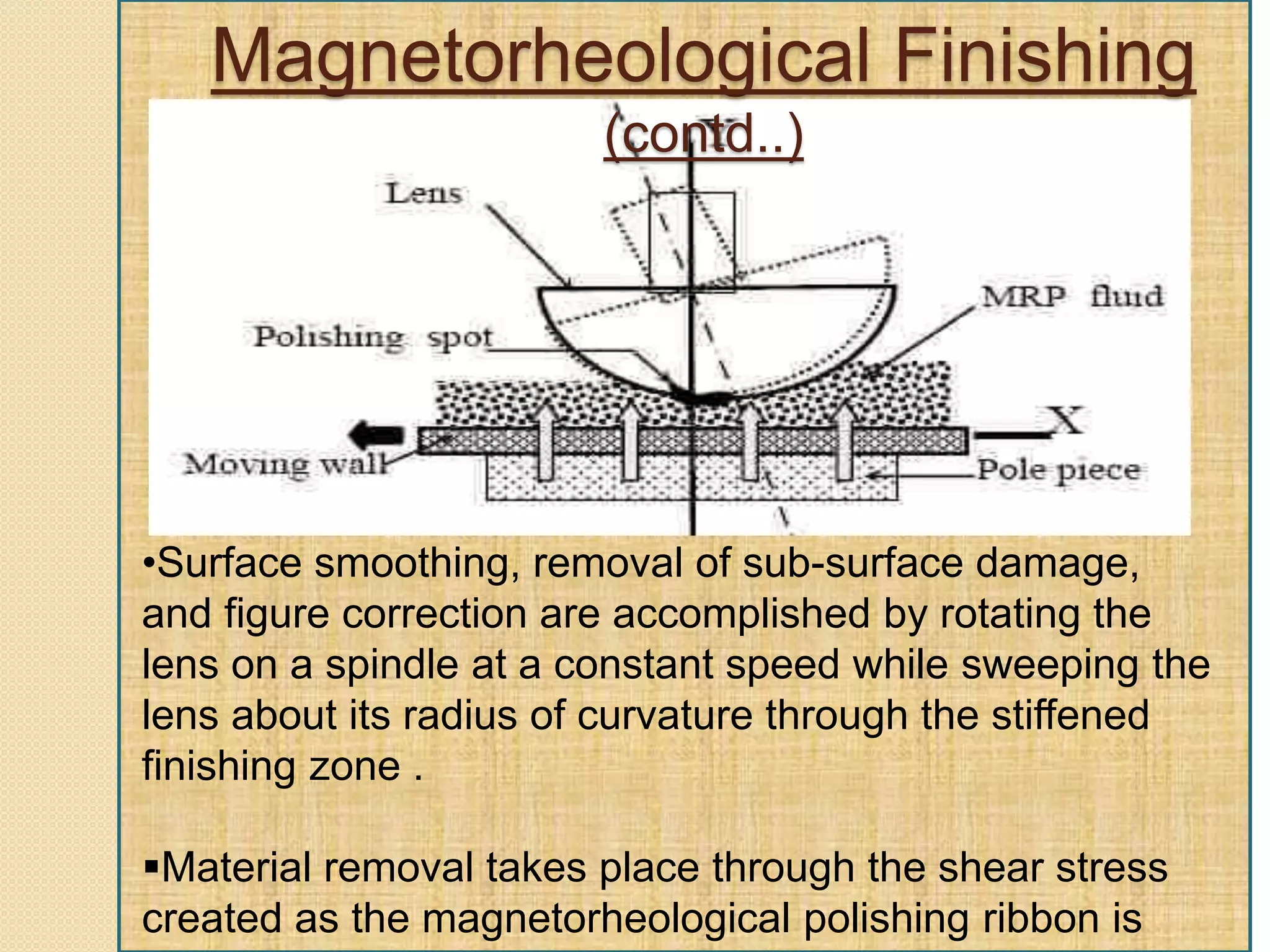

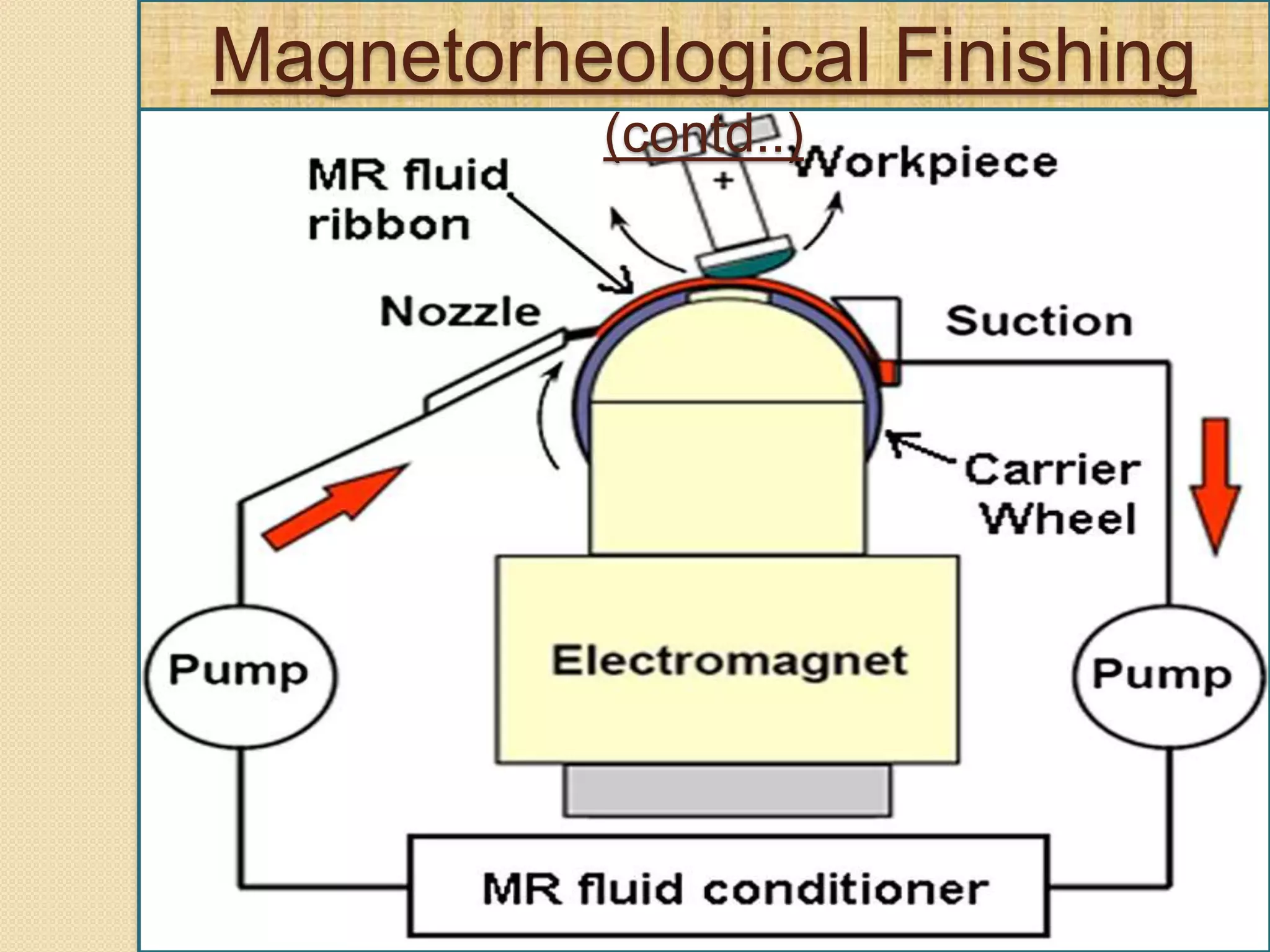

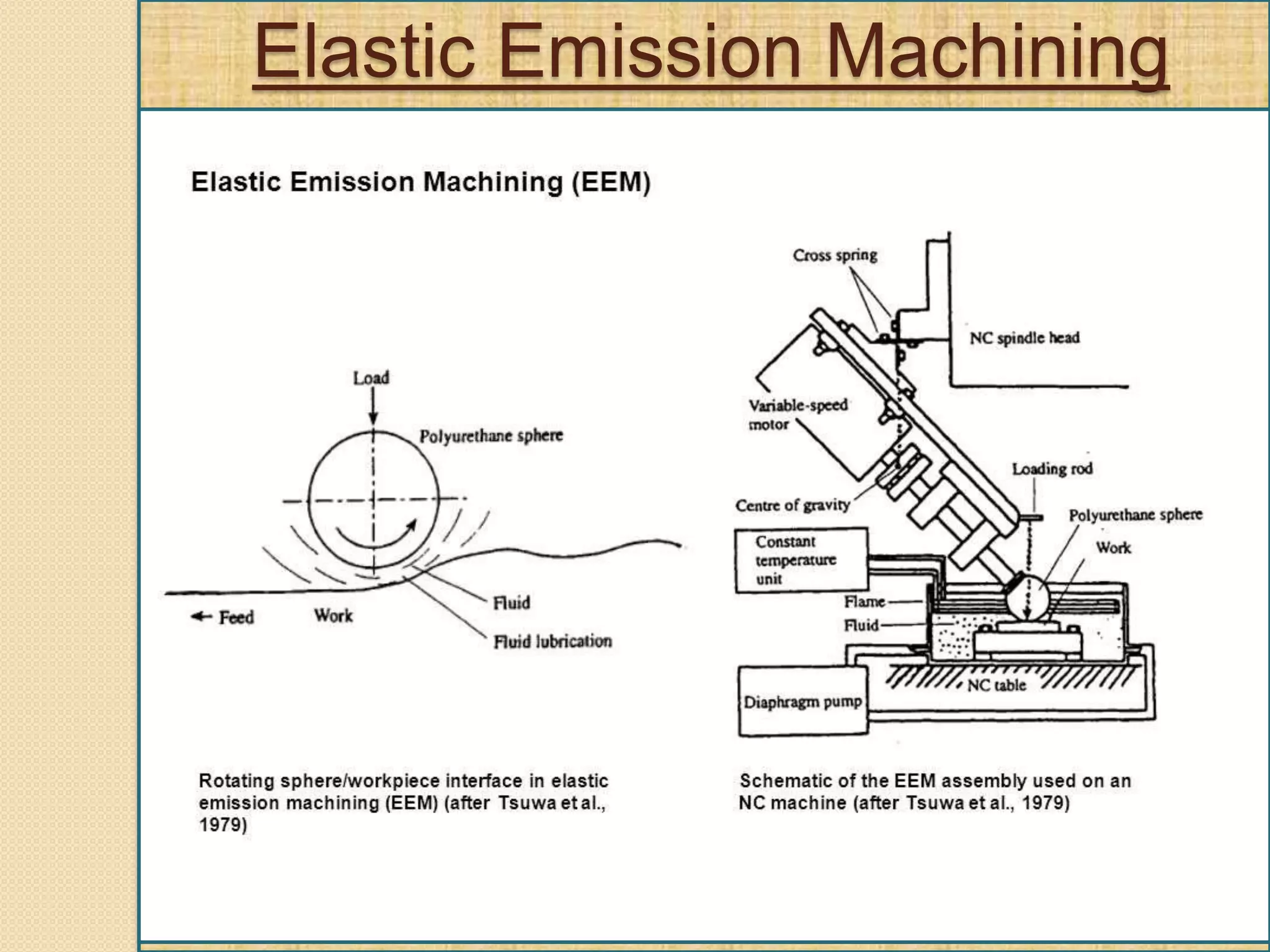

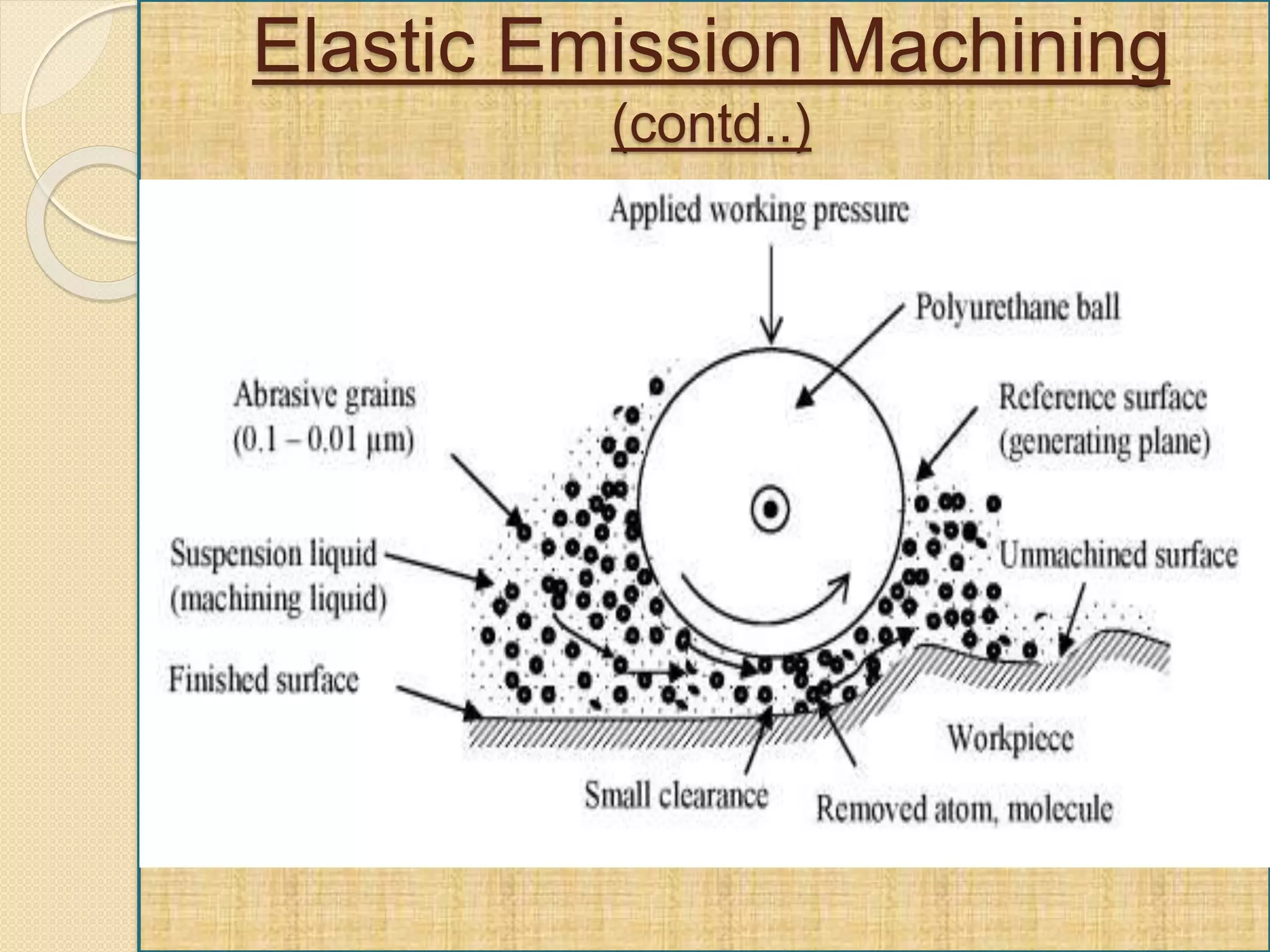

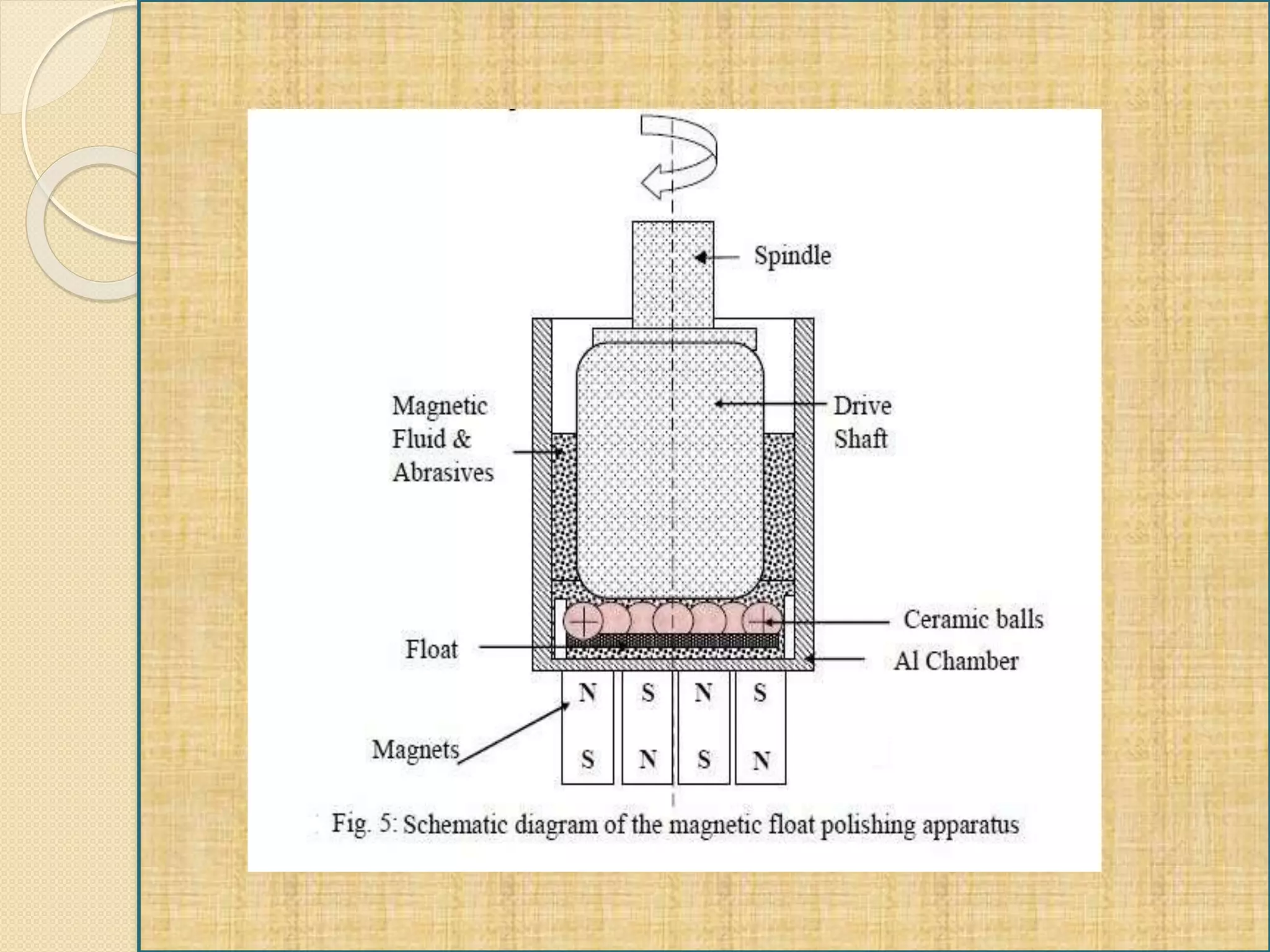

Nanofinishing techniques have been developed to achieve surface finishes on the nanometer scale for applications in electronics, optics, and other industries. Some key nanofinishing processes include magnetic abrasive finishing, magnetorheological finishing, elastic emission machining, magnetic float polishing, and ion beam machining. These processes use techniques such as magnetic fields, abrasives, and ion bombardment to remove material from surfaces at the atomic level and achieve roughness in the range of 0.1 to 7.6 nm. Nanofinishing enables high-precision machining for applications such as medical devices and computer components.