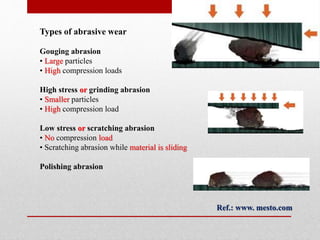

Wear is the process of material removal from solid surfaces that are in contact with each other due to sliding or rolling motion. It occurs on the surface of a component as a result of its motion relative to an adjacent working part and depends on factors like surface geometry, applied load, velocities, environment, and material properties. The main types of wear processes are abrasive wear, adhesive wear, surface fatigue, and erosive wear. Abrasive wear occurs when a harder surface rubs against a softer one.