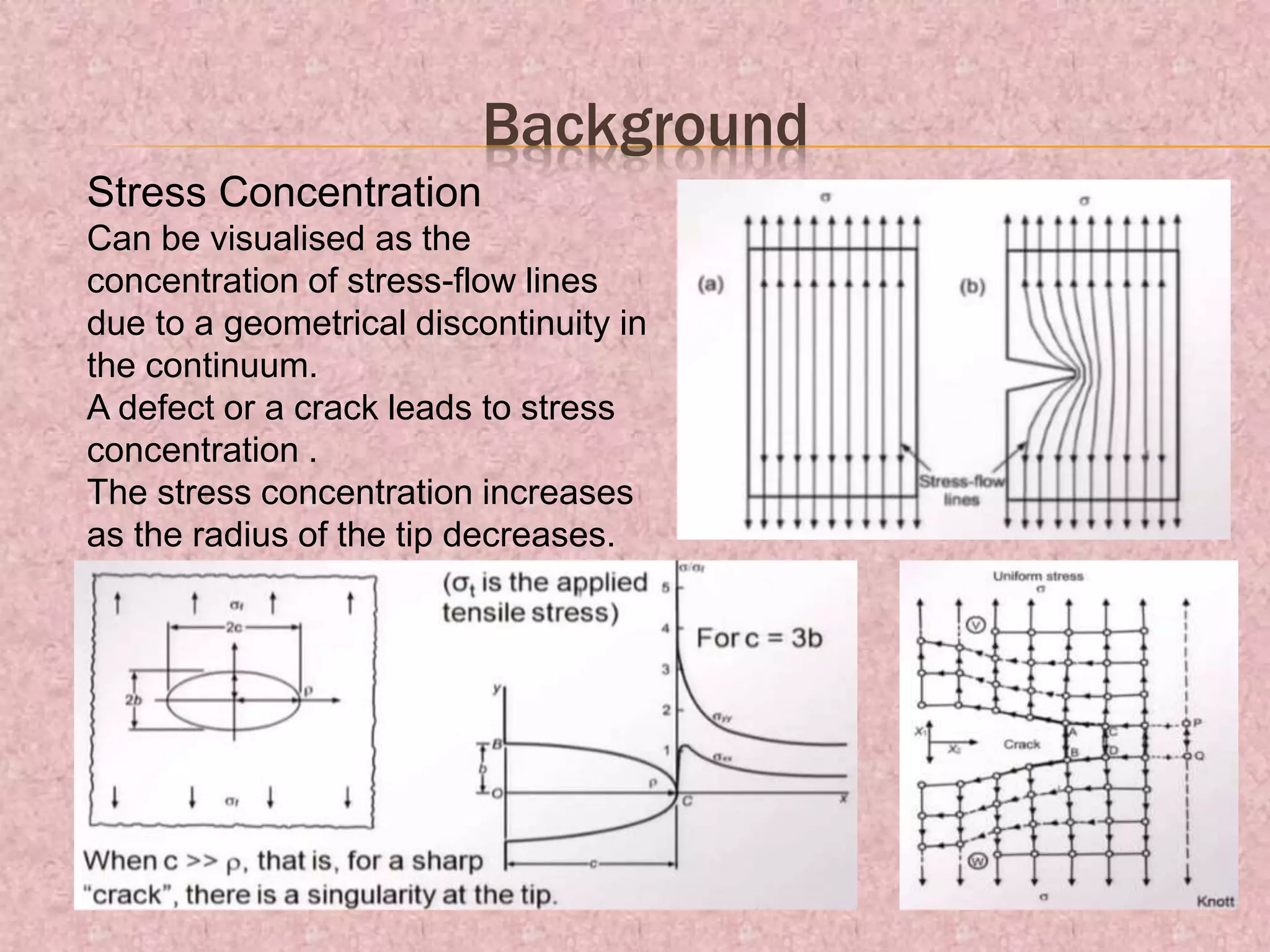

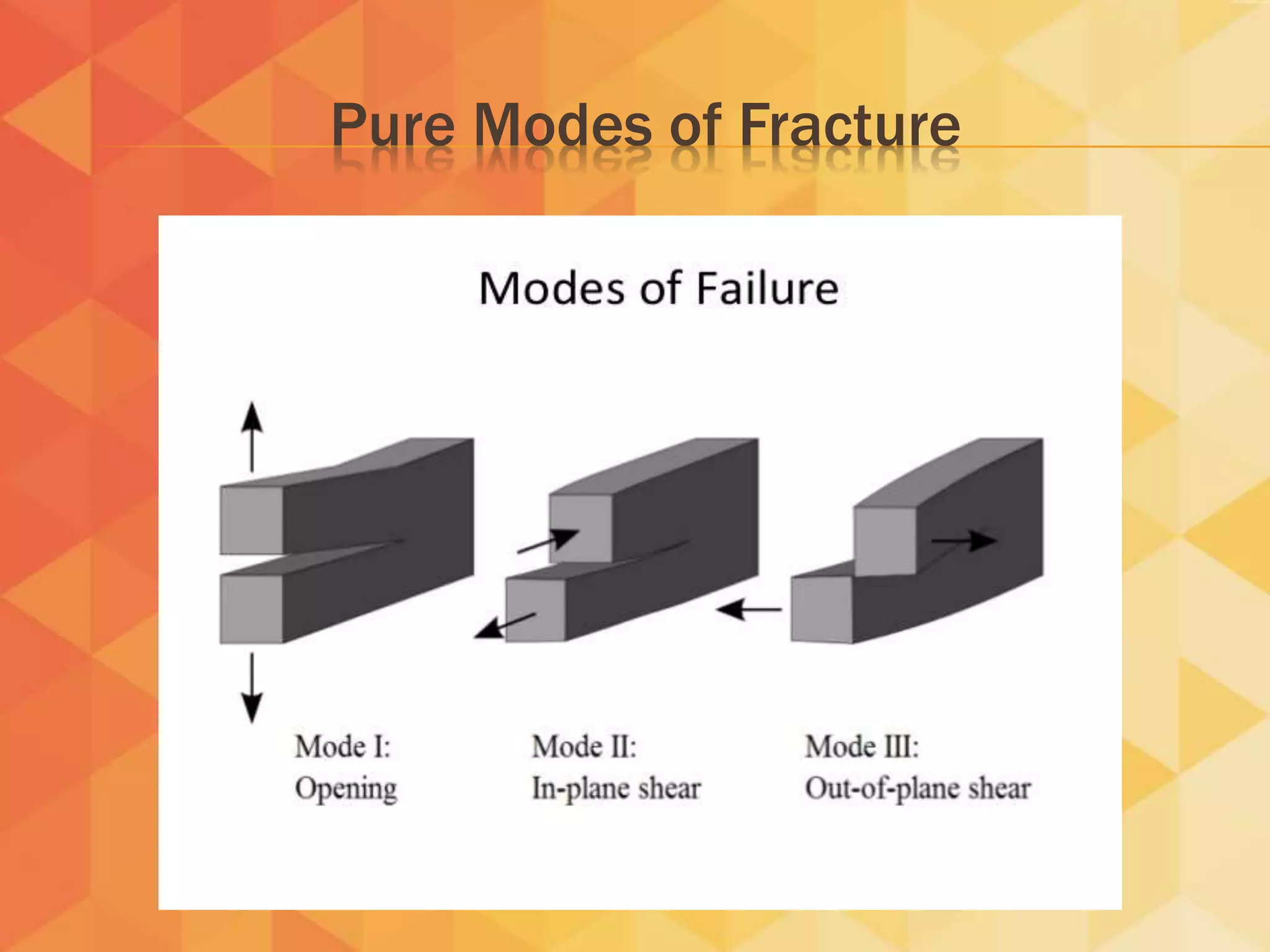

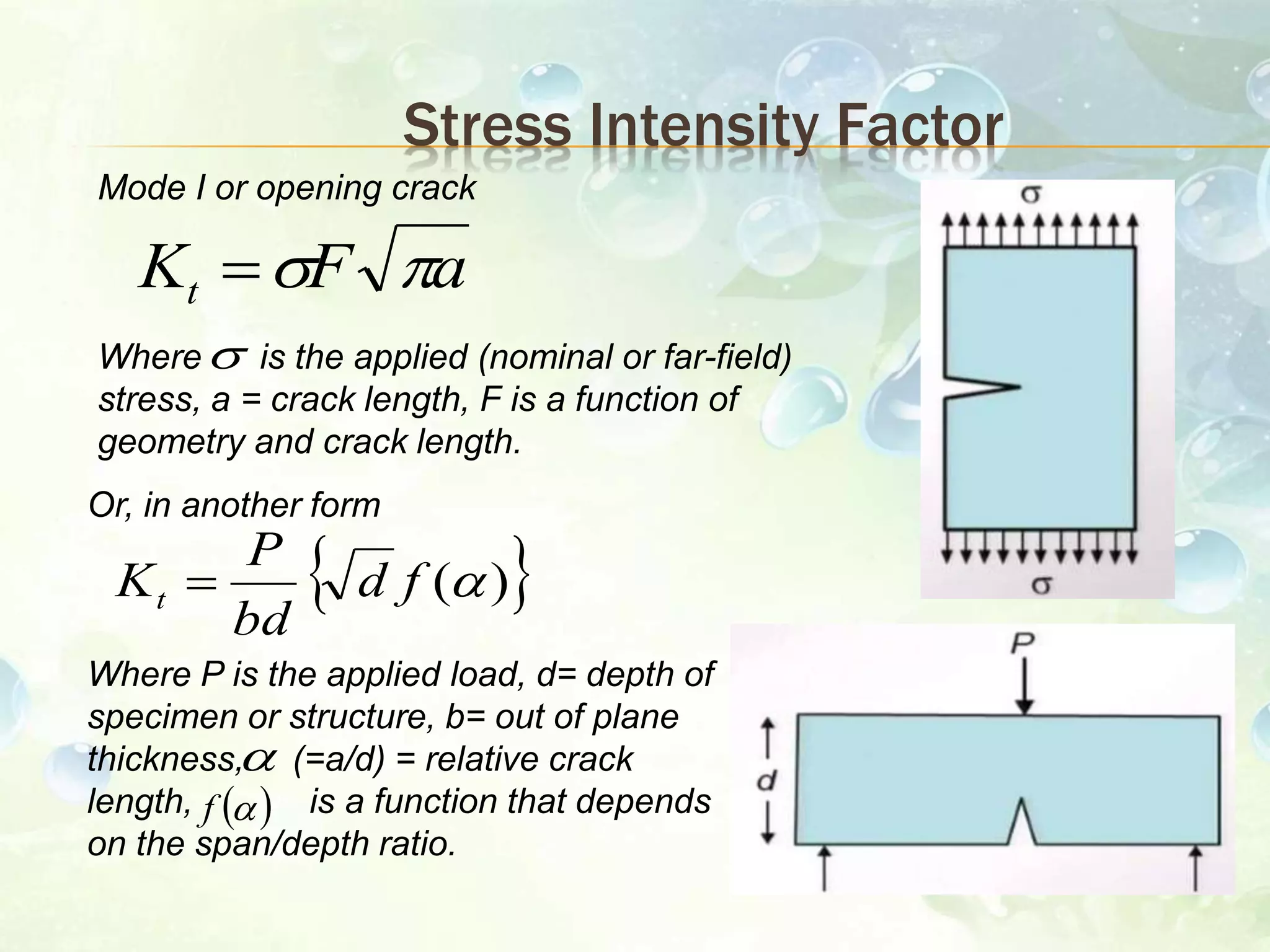

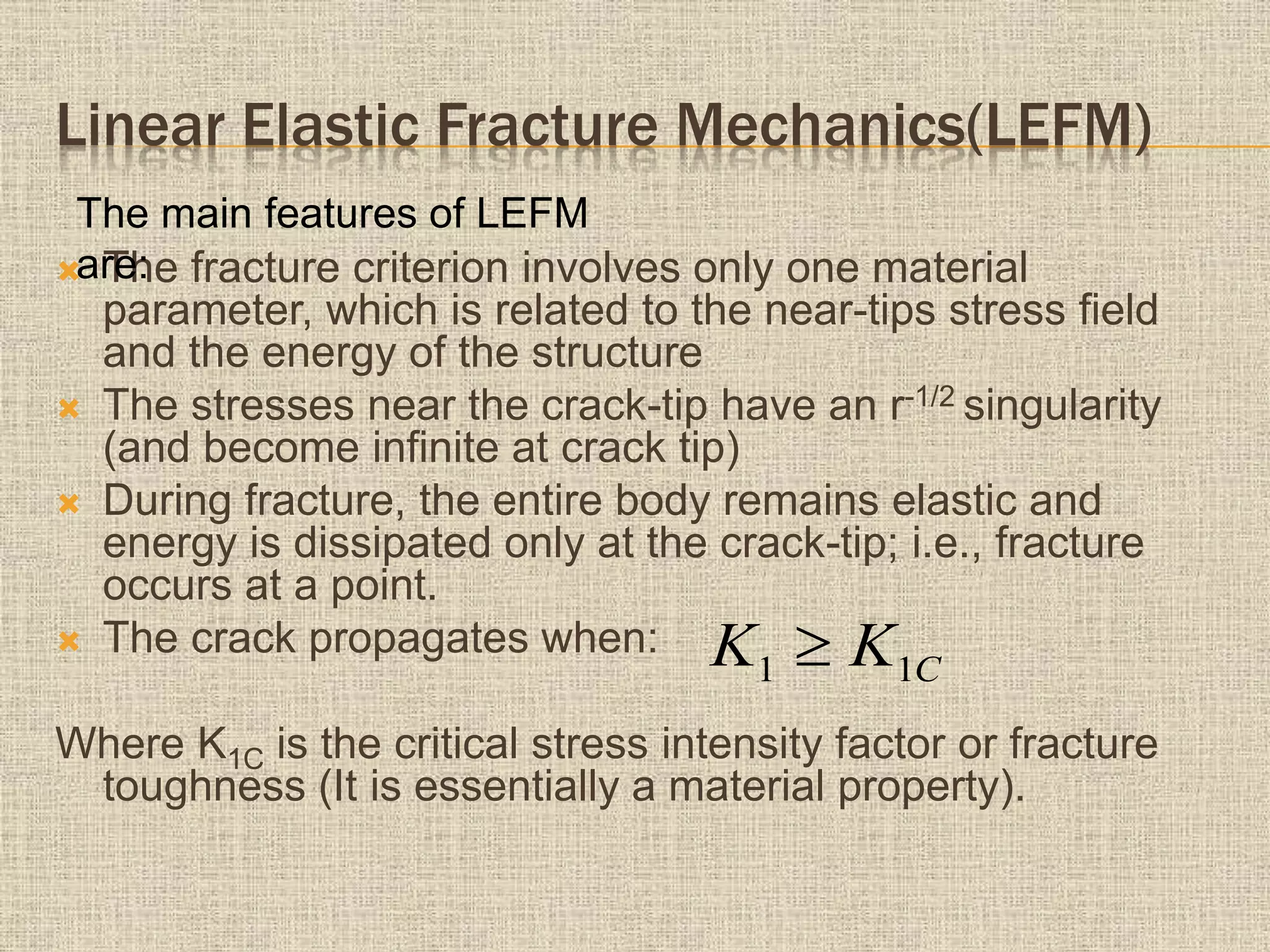

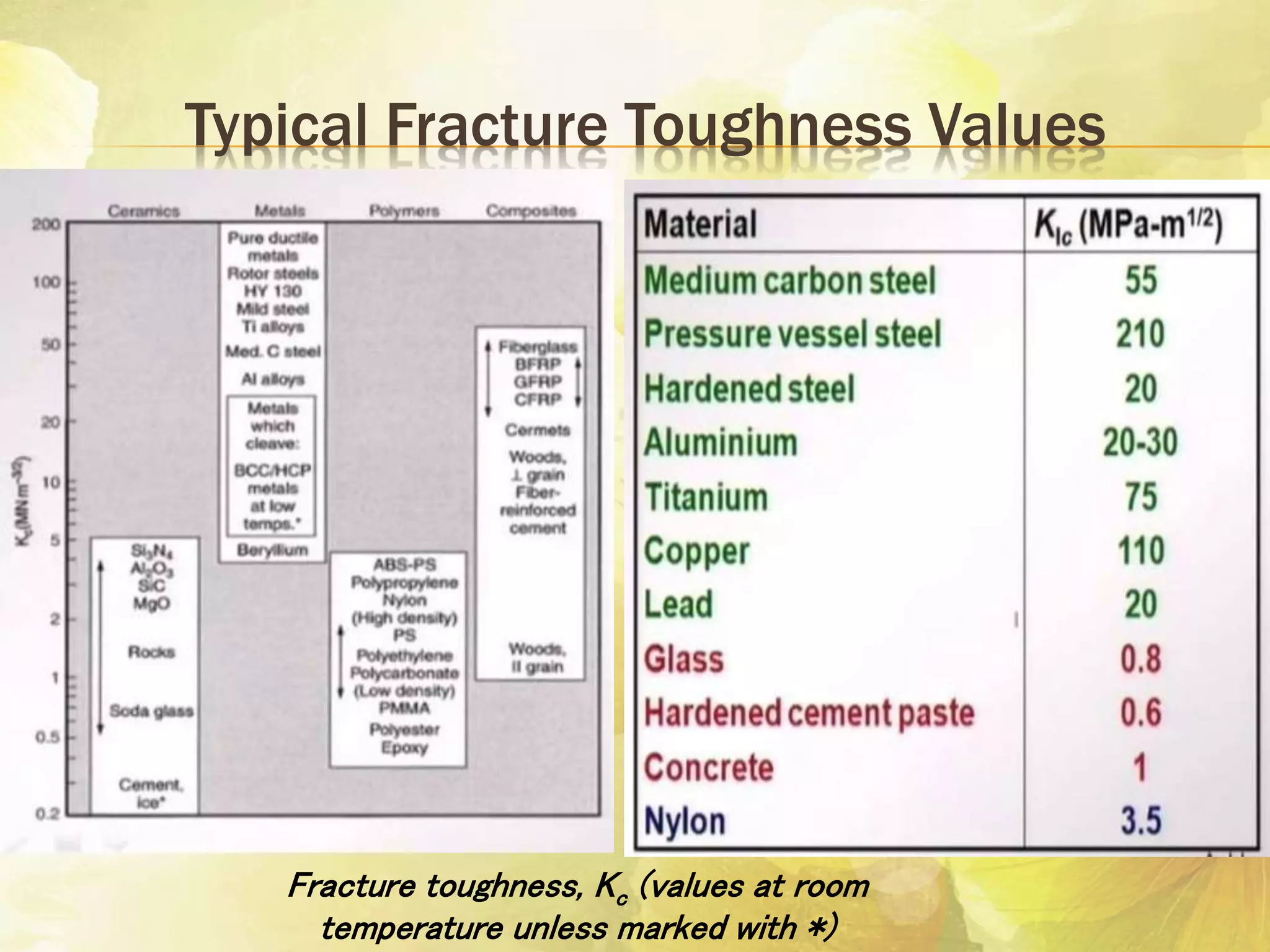

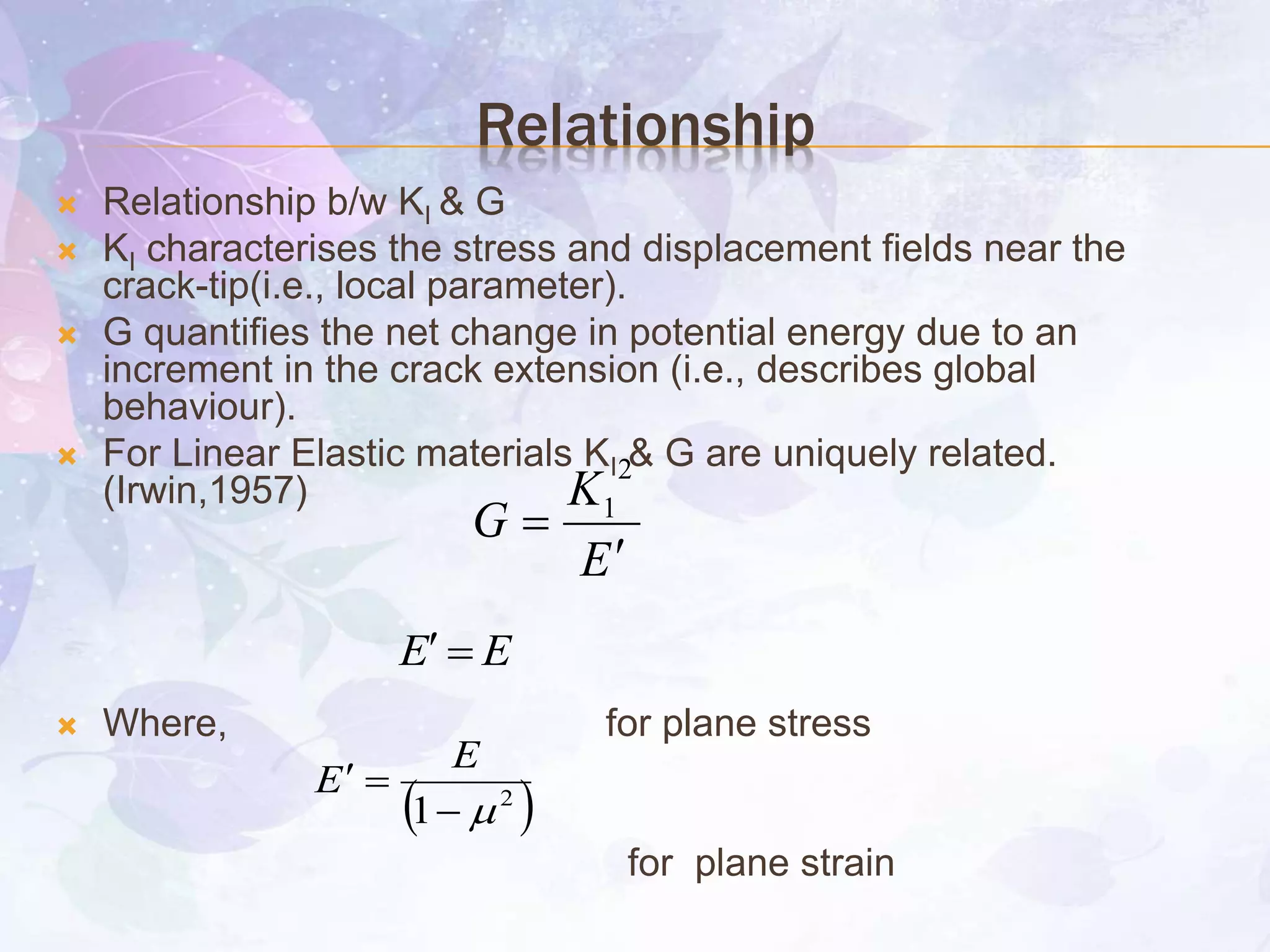

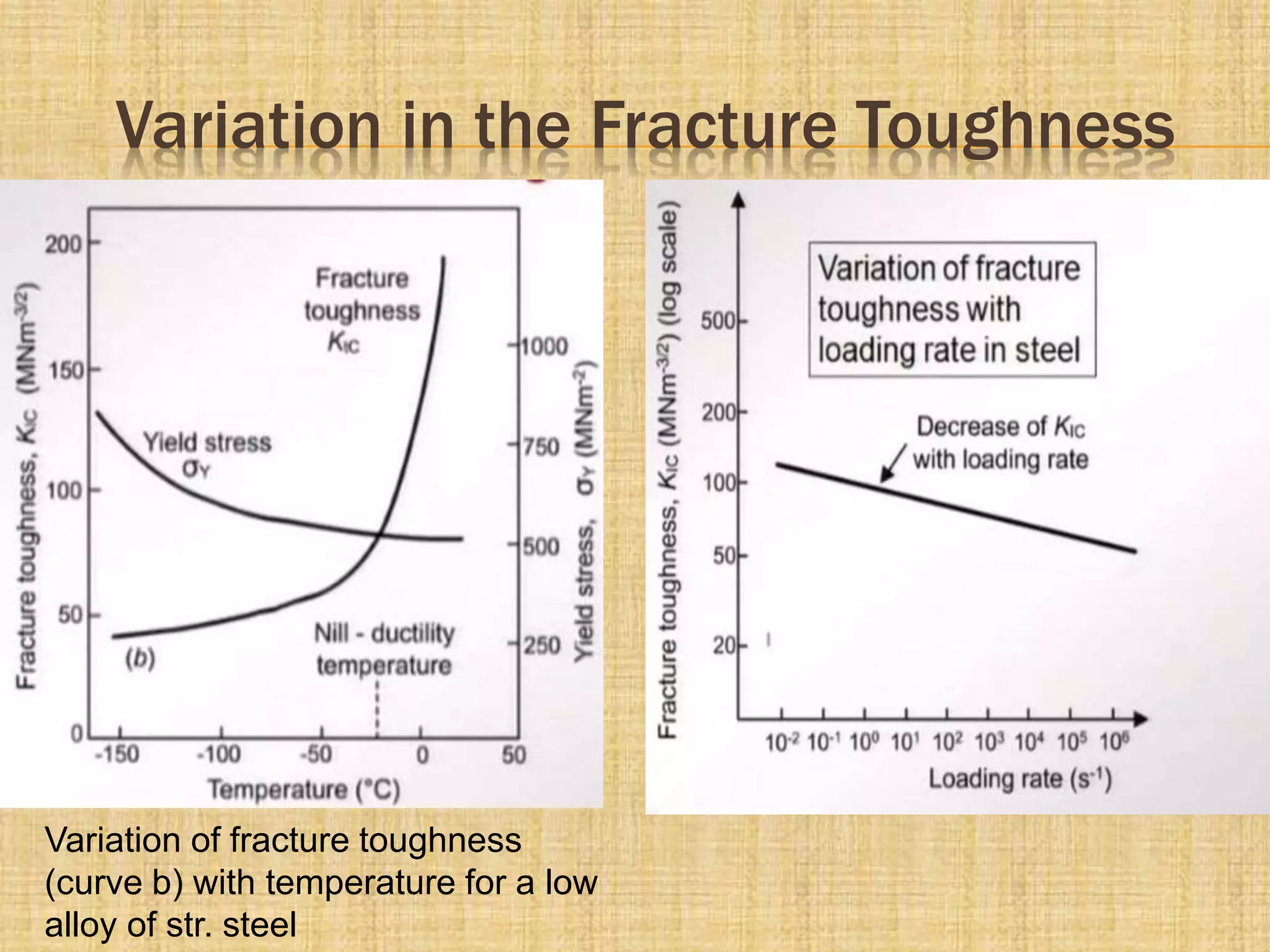

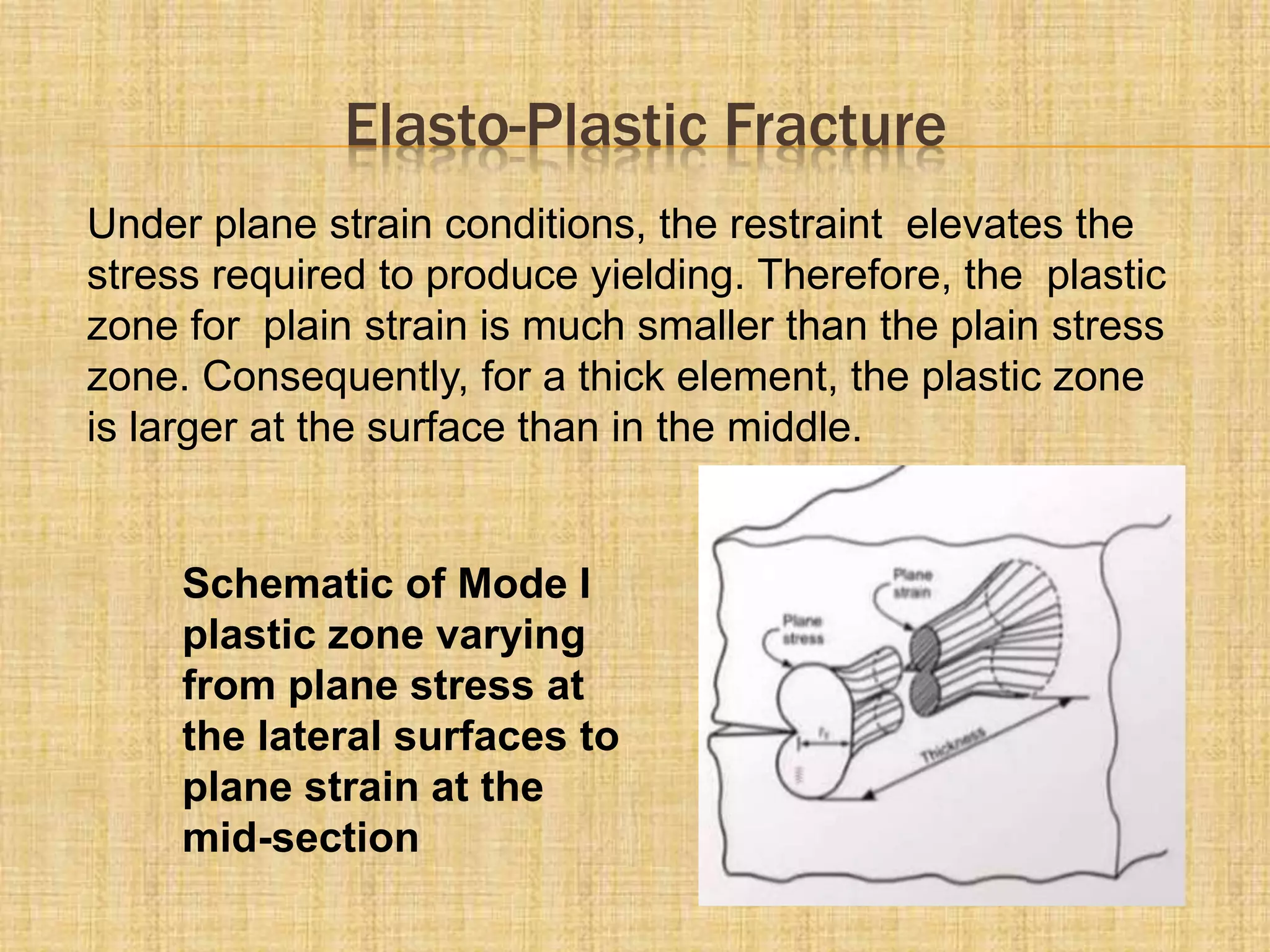

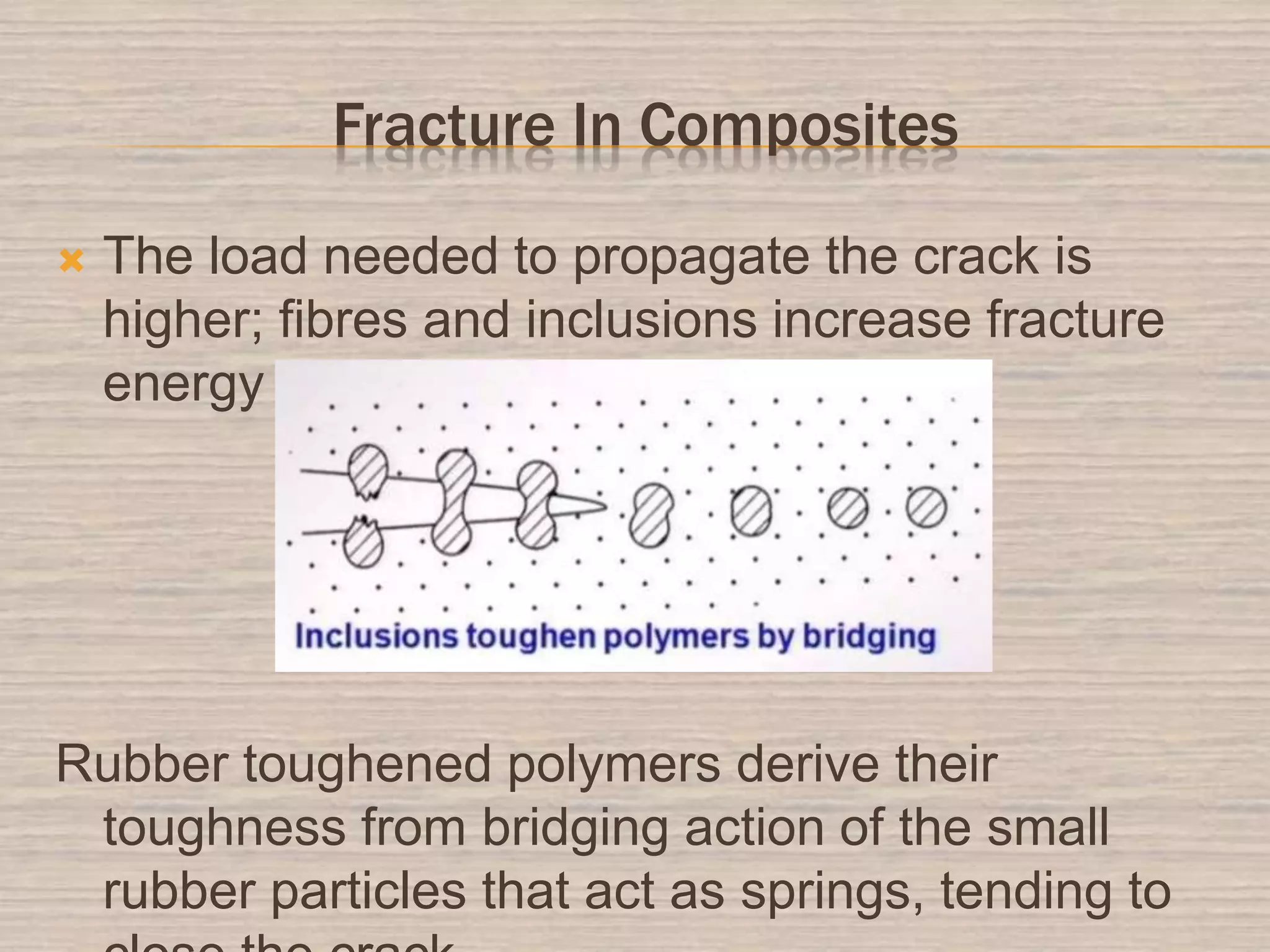

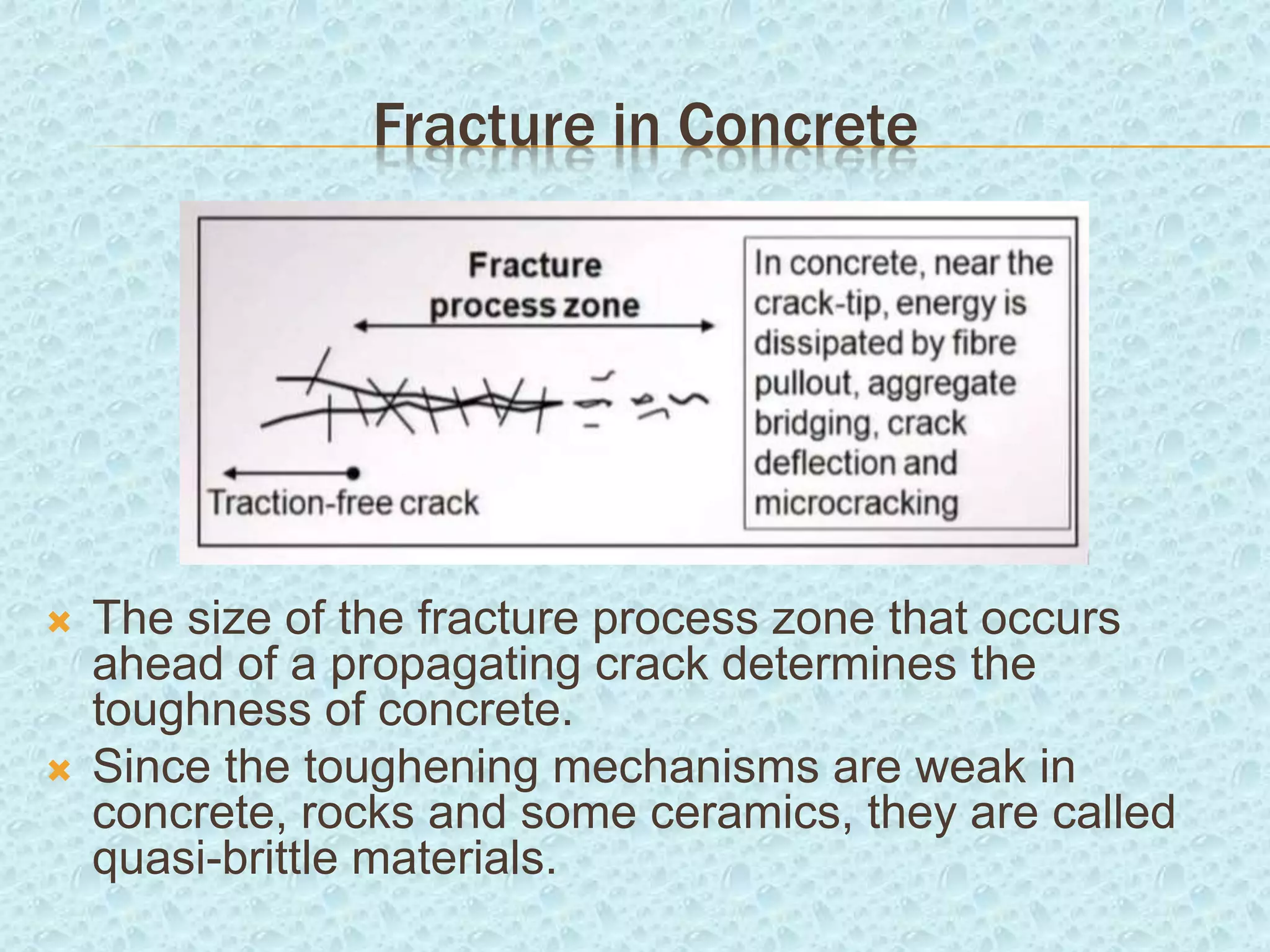

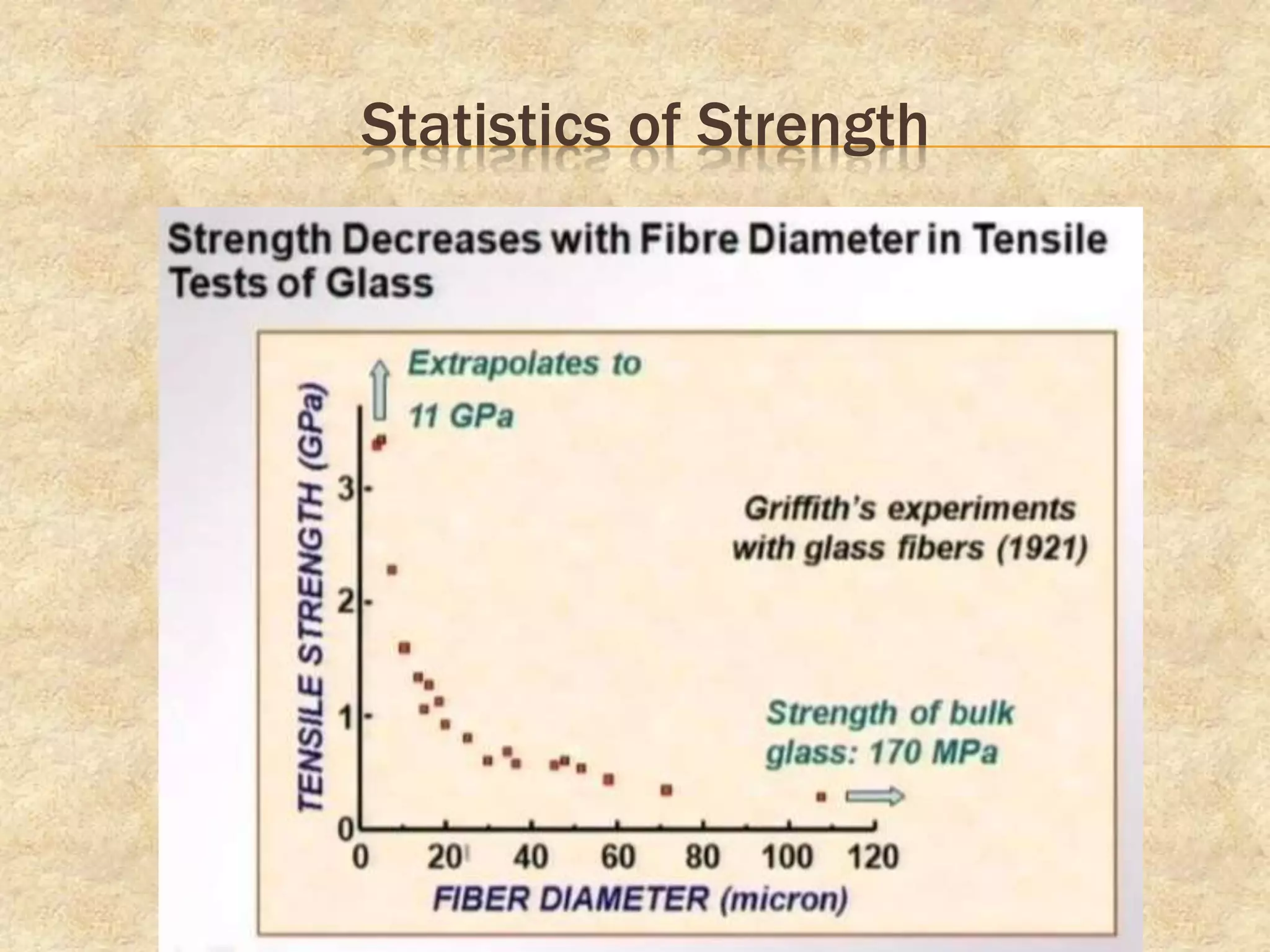

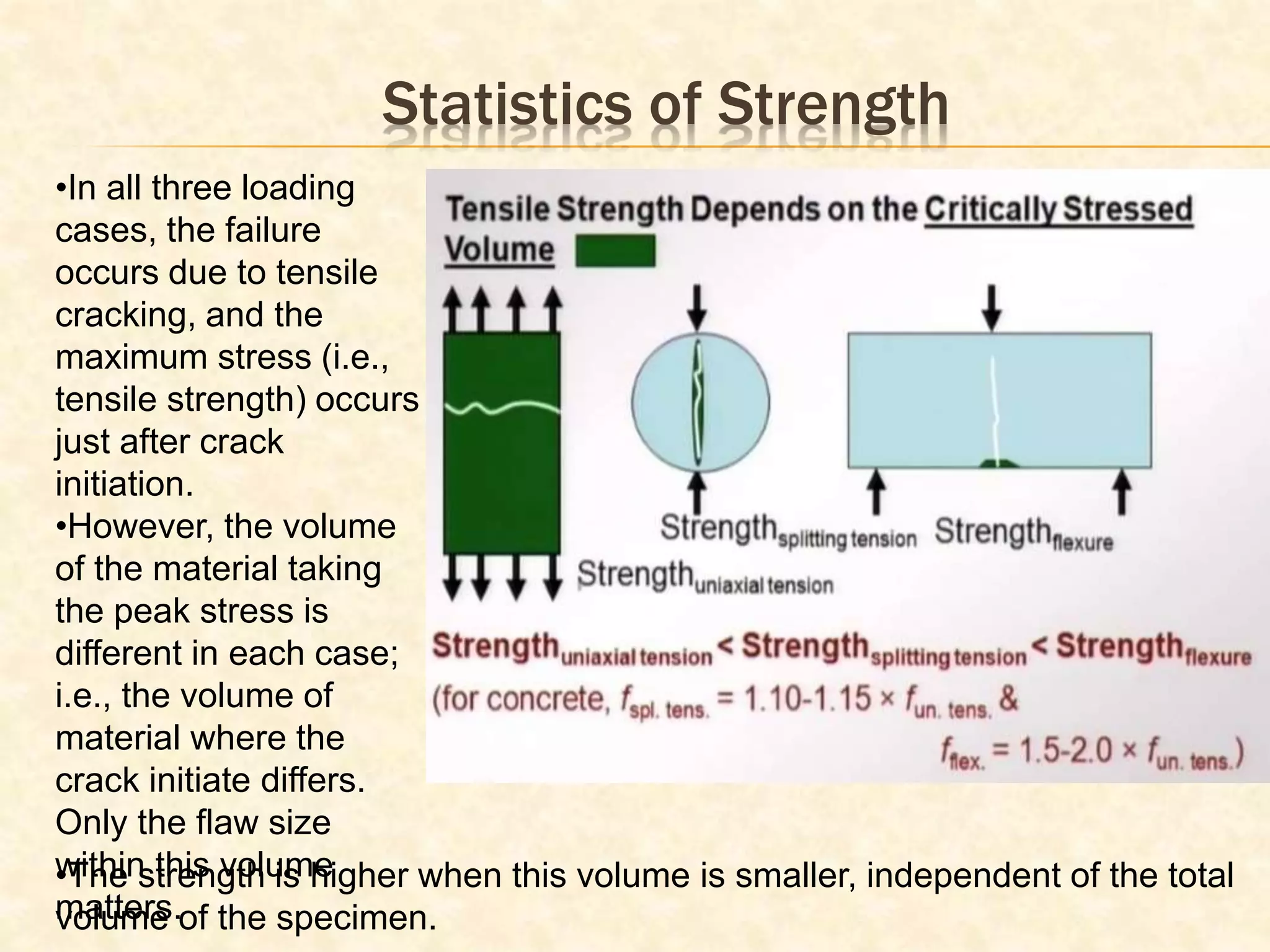

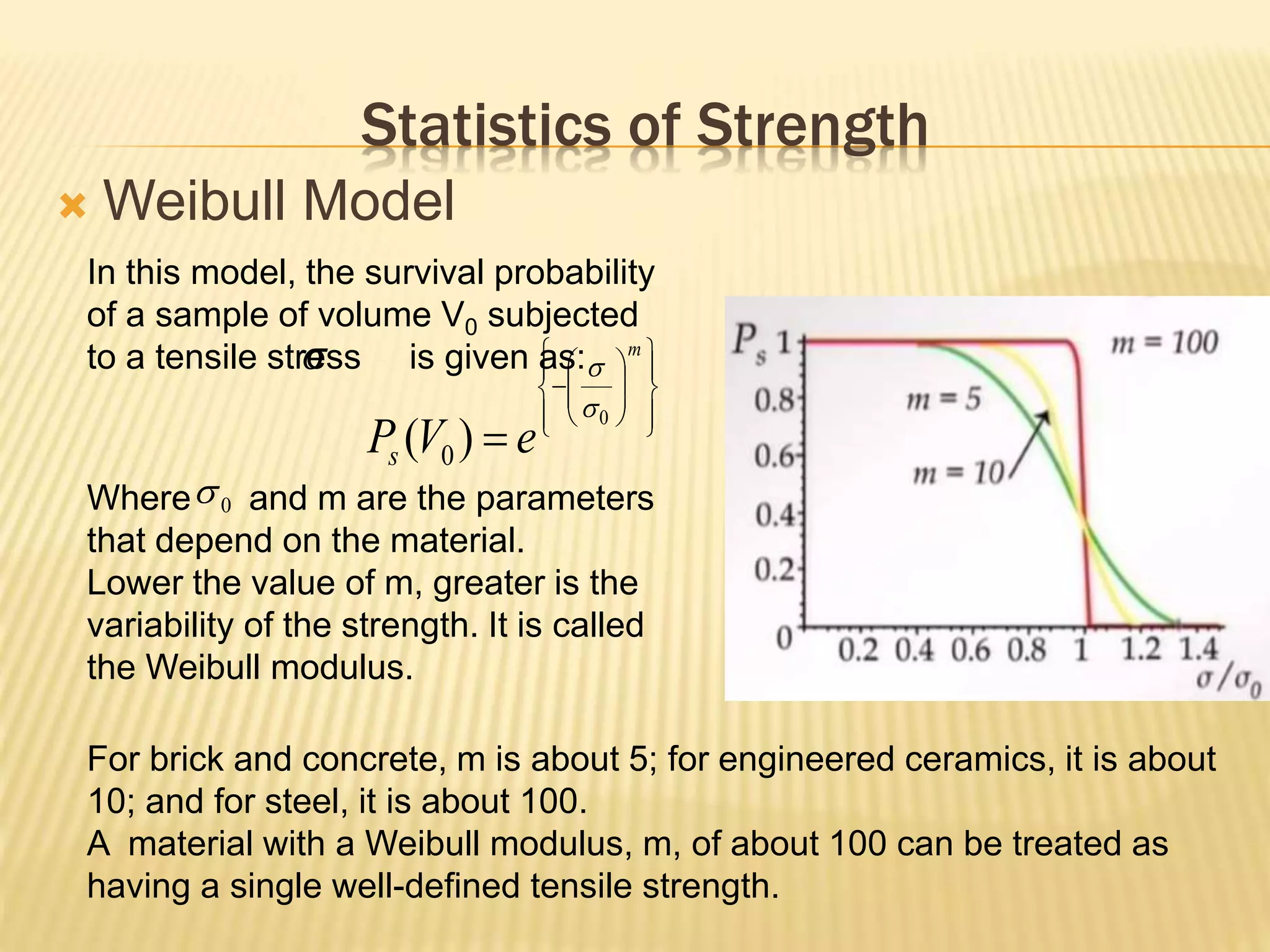

This document discusses fracture mechanics and provides background information on the topic. It introduces key concepts in fracture mechanics including stress intensity factor, linear elastic fracture mechanics (LEFM), ductile to brittle transition, and fracture toughness. Applications of fracture mechanics are described such as its use in analyzing cracking in pavement systems. The document also covers probabilistic fracture of brittle materials and how their strength is affected by the presence of flaws.