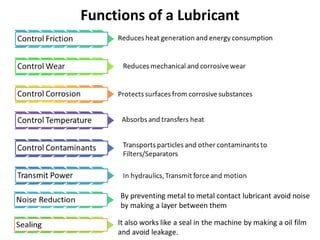

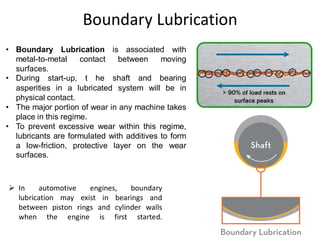

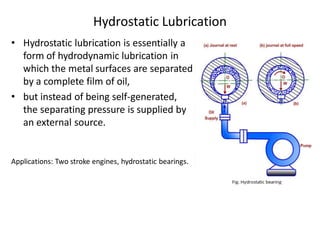

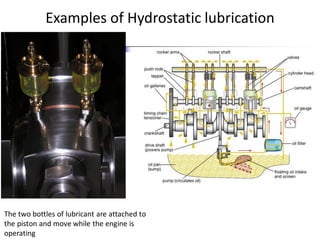

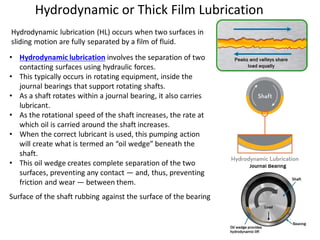

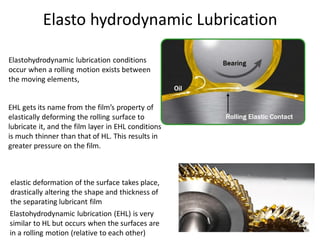

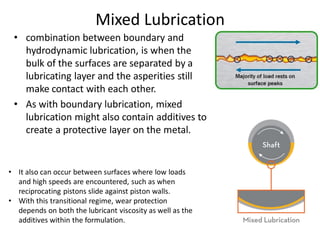

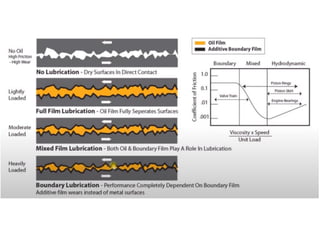

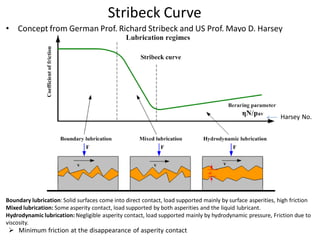

This document discusses different types of lubrication used in mechanical systems. It describes boundary lubrication as metal-to-metal contact that occurs during startup. Hydrostatic lubrication uses an external pressure source to separate surfaces with a lubricant film. Hydrodynamic lubrication fully separates surfaces using hydraulic forces generated by fluid viscosity as surfaces move. Elastohydrodynamic lubrication involves rolling contact that elastically deforms surfaces to lubricate them. Mixed lubrication is a combination of boundary and hydrodynamic lubrication, where asperities still contact but surfaces are mostly separated. The Stribeck curve illustrates the relationship between friction and the lubrication regime from boundary to hydrodynamic.