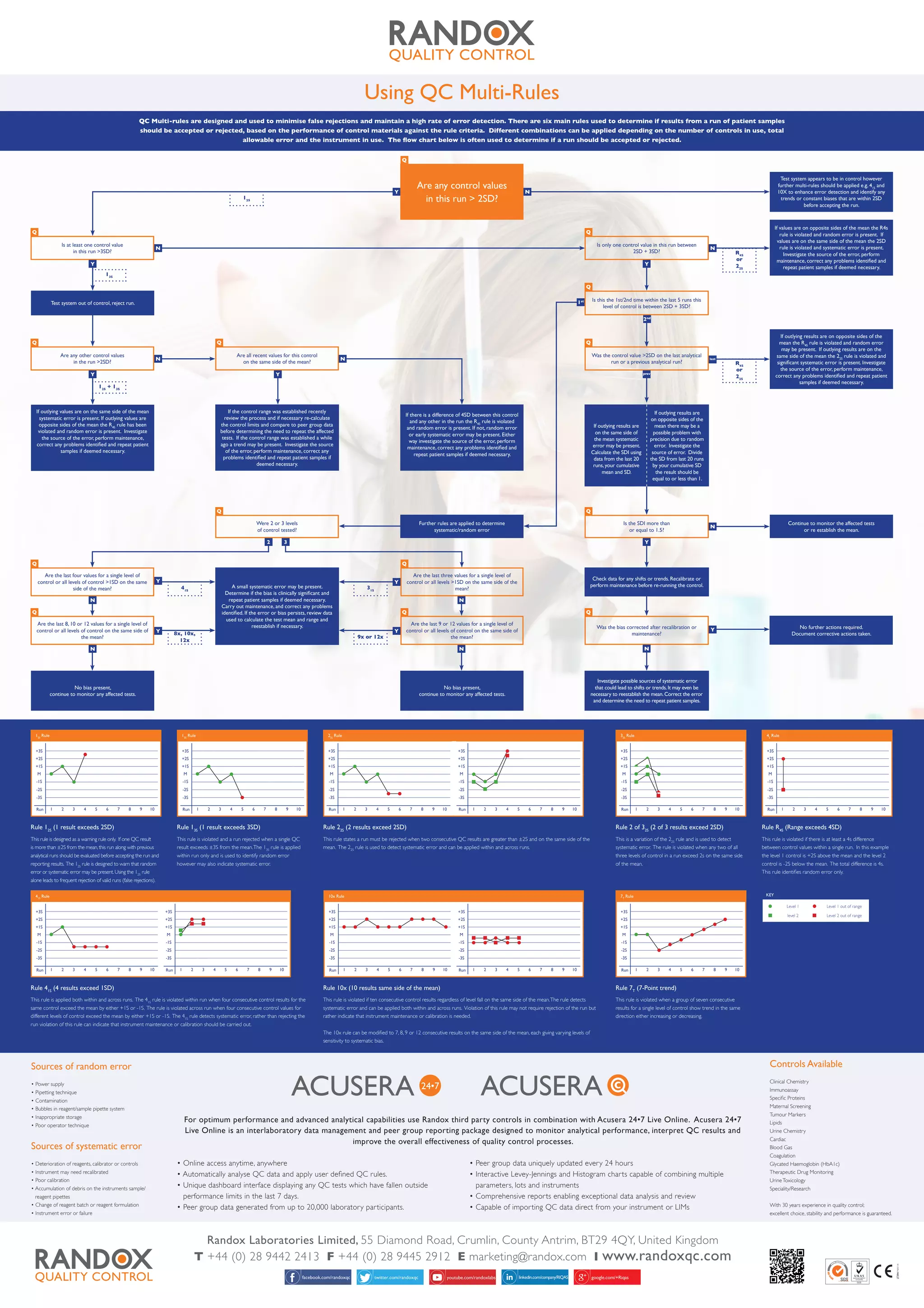

The document outlines a set of QC multi-rules used to minimize false rejections and ensure high error detection rates in laboratory testing. It describes various rules for evaluating control results, including rules for identifying random and systematic errors, and emphasizes the importance of maintenance and calibration. Additionally, it highlights the capabilities of Randox's quality control system and the need for careful analysis of QC data.