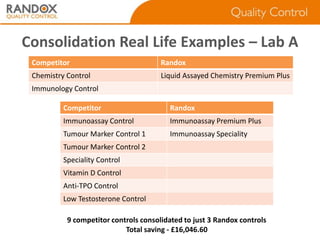

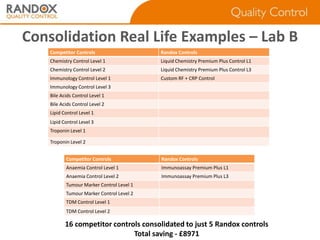

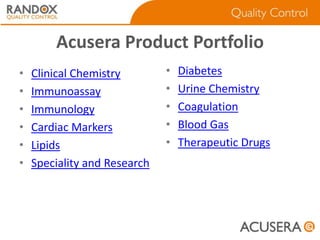

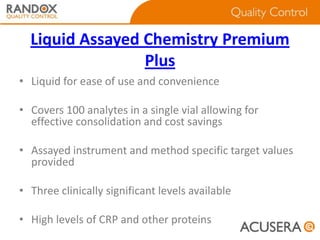

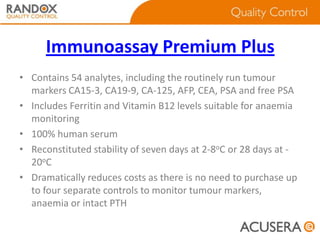

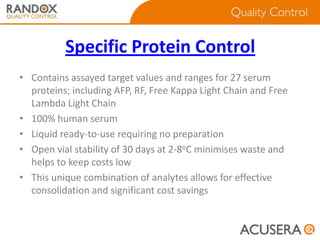

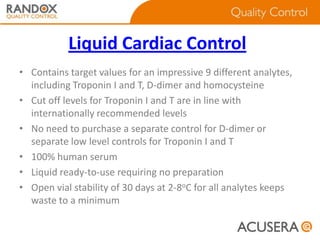

Randox is a leading provider of true third party quality controls for laboratories. Their controls offer the most accurate target values based on data from over 23,000 labs, the most consistent material between lots, and unrivalled stability that meets or exceeds claims. Many controls are 100% human material, important for immunoassay methods. As true third party controls, they provide an unbiased assessment of performance across different instruments and methods, reducing the need for multiple controls. Randox controls also allow for consolidation, reducing the number of individual controls required through their wide coverage of analytes.