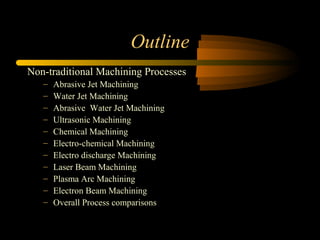

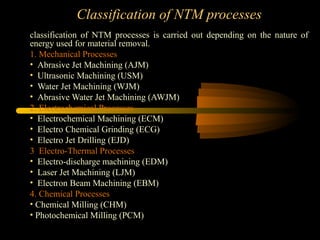

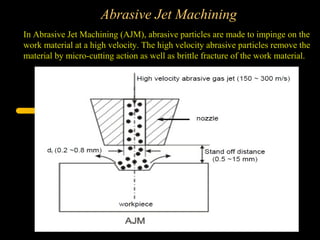

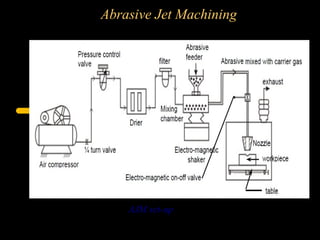

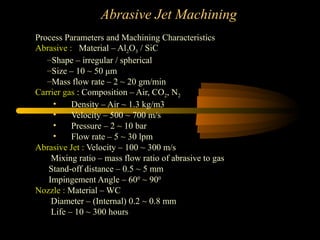

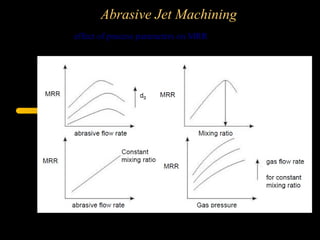

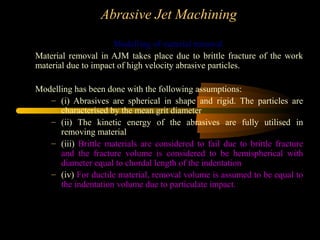

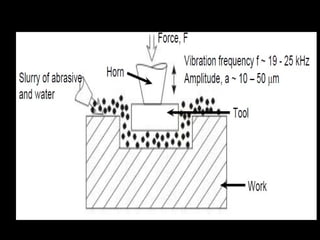

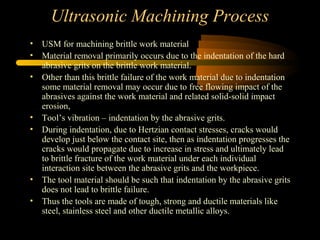

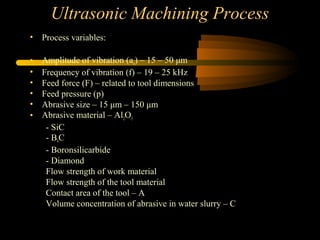

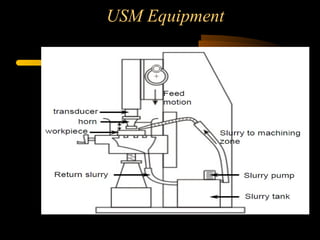

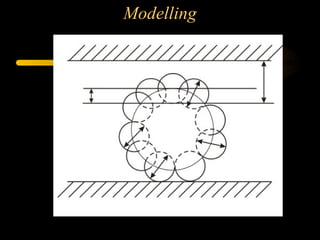

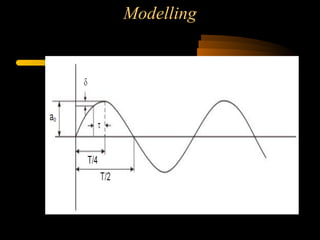

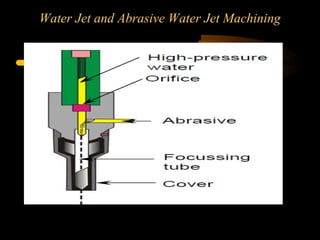

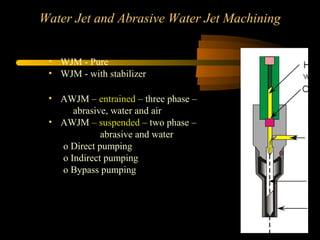

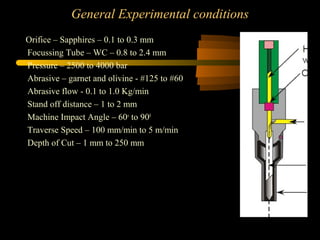

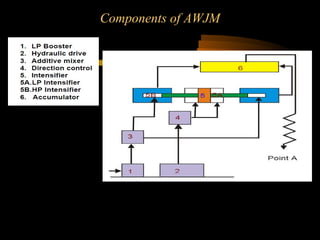

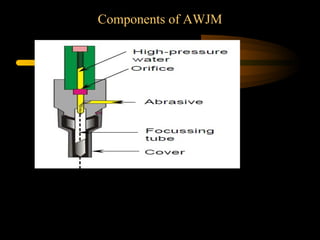

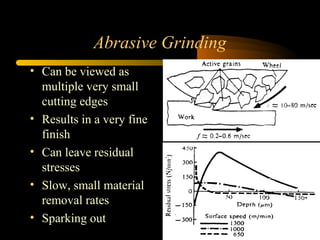

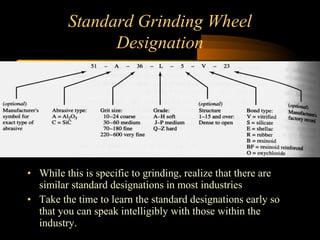

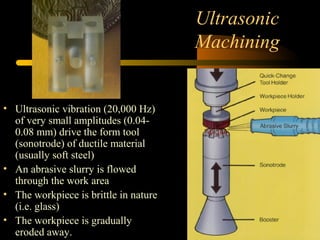

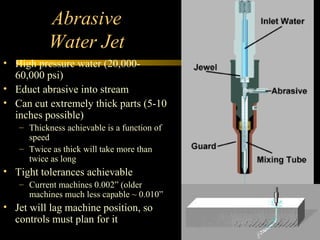

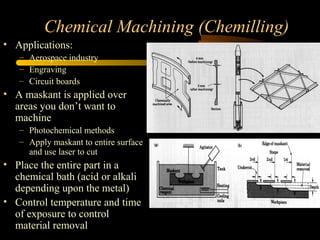

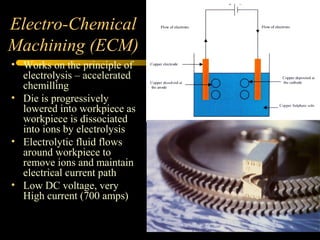

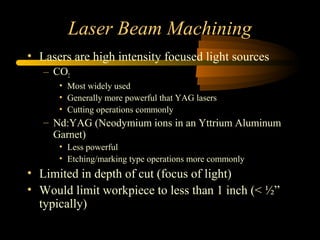

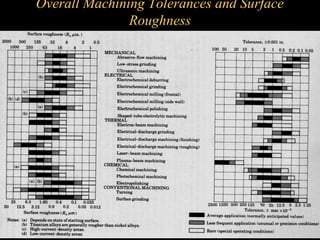

The document presents an overview of unconventional machining processes, categorizing them into various types including abrasive jet machining, water jet machining, and electro-chemical machining. It outlines the characteristics of non-traditional machining methods, highlighting their advantages in machining hard or complex materials that are challenging for conventional methods. Additionally, it discusses specific processes such as ultrasonic machining, laser beam machining, and their respective parameters and applications in the manufacturing sector.