This document provides an overview of 3D printing and tooling. It begins by stating the educational objectives and outcomes of the course, which are to understand the principles, methods, materials, possibilities, limitations and environmental effects of additive manufacturing technologies.

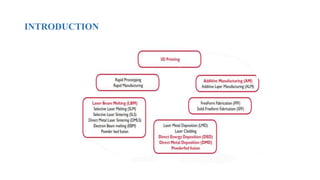

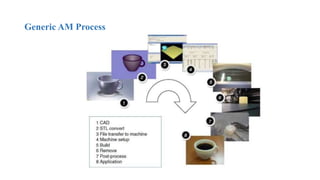

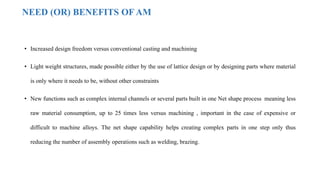

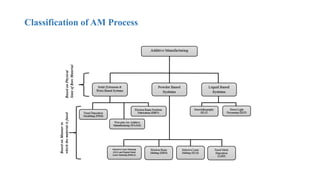

The document then covers the different units that will be taught, with the first unit providing an introduction to additive manufacturing. It discusses the history and need for additive manufacturing, provides a classification of the different technologies, and discusses how additive manufacturing is used in product development. It also introduces the different materials that can be used for additive manufacturing.

In closing, the document emphasizes that additive manufacturing enables both a design and industrial revolution across many industries such as aerospace, energy, automotive