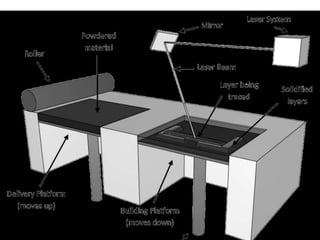

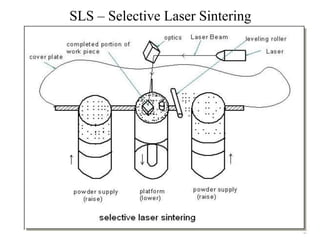

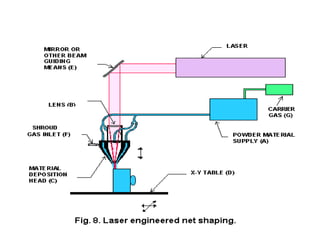

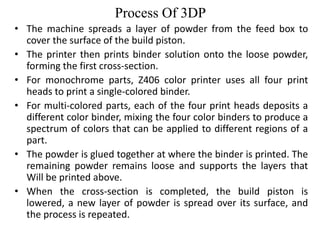

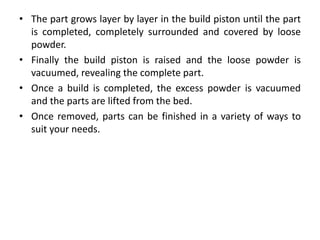

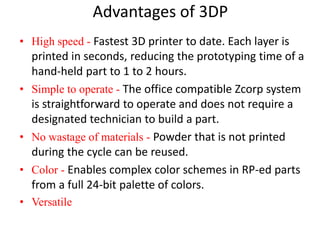

The document discusses three powder-based additive manufacturing systems: selective laser sintering (SLS), three dimensional printing (3DP), and laser engineered net shaping (LENS). SLS uses a laser to sinter powdered materials like plastic and metal together layer by layer. 3DP uses inkjet printheads to apply a binder to layers of powder to build parts. LENS uses a laser to melt metal powder as it is deposited, building parts layer by layer. Each system uses a different technique but all use lasers or binders to fuse powdered materials together to build 3D parts additively.