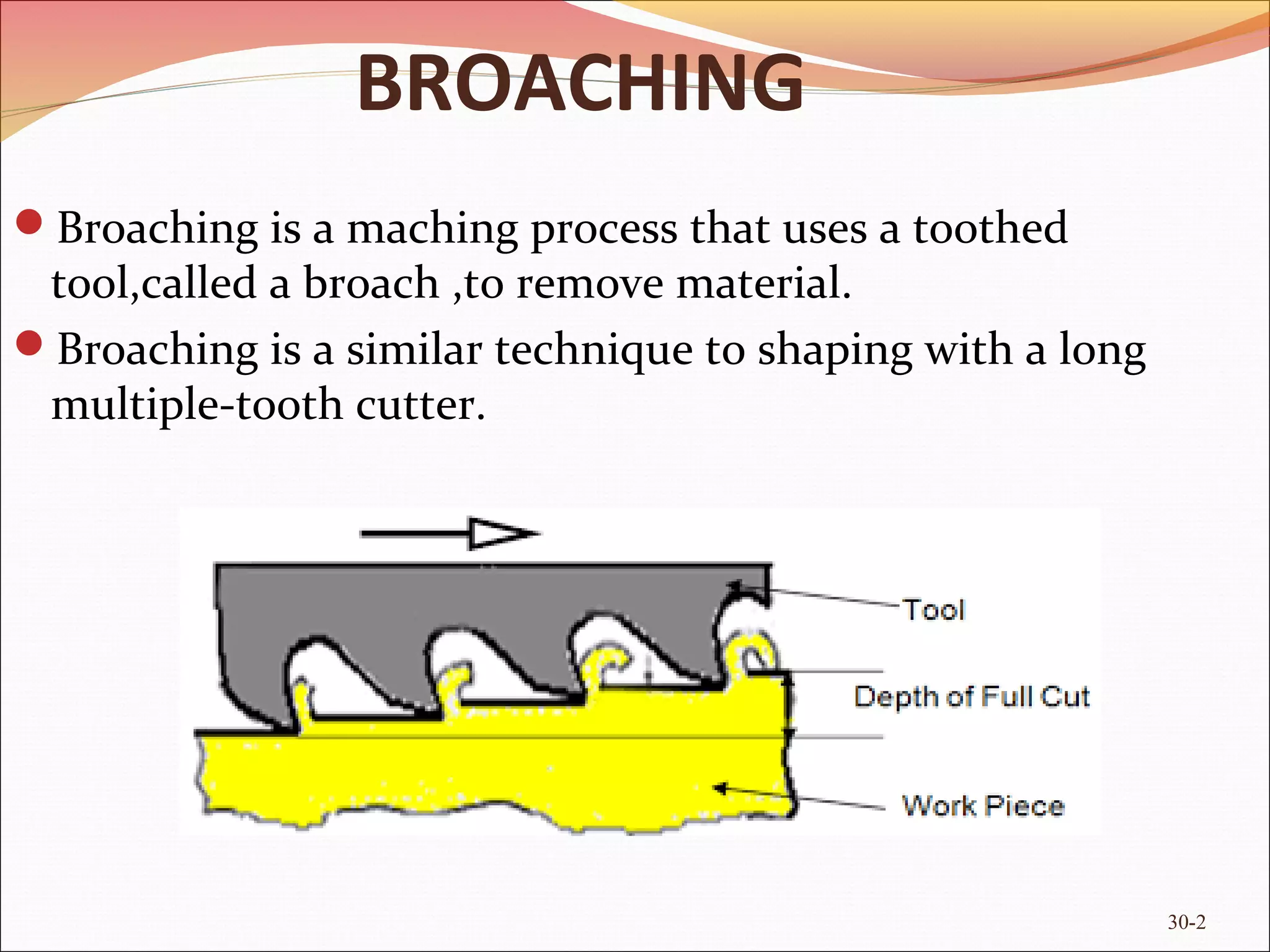

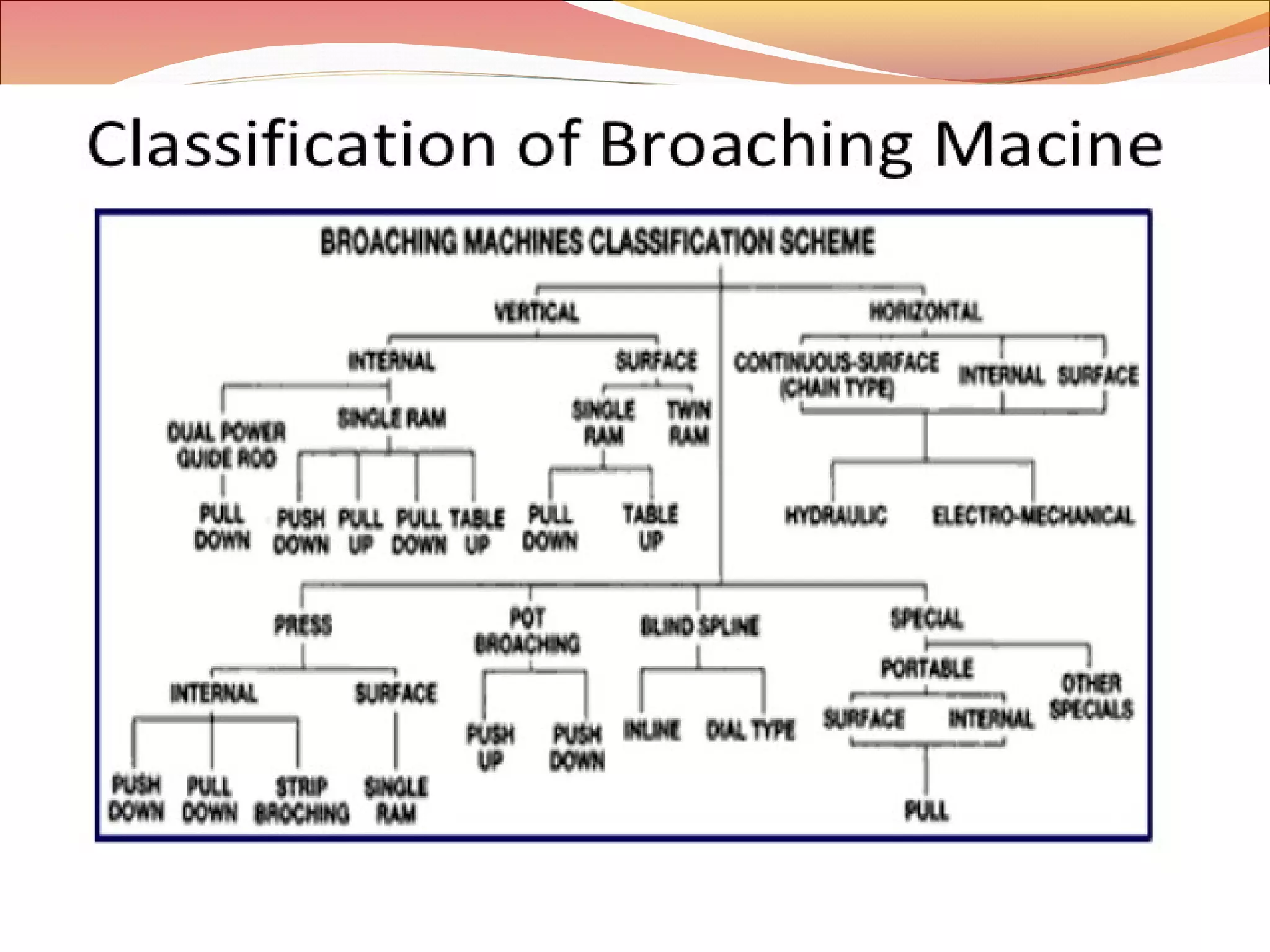

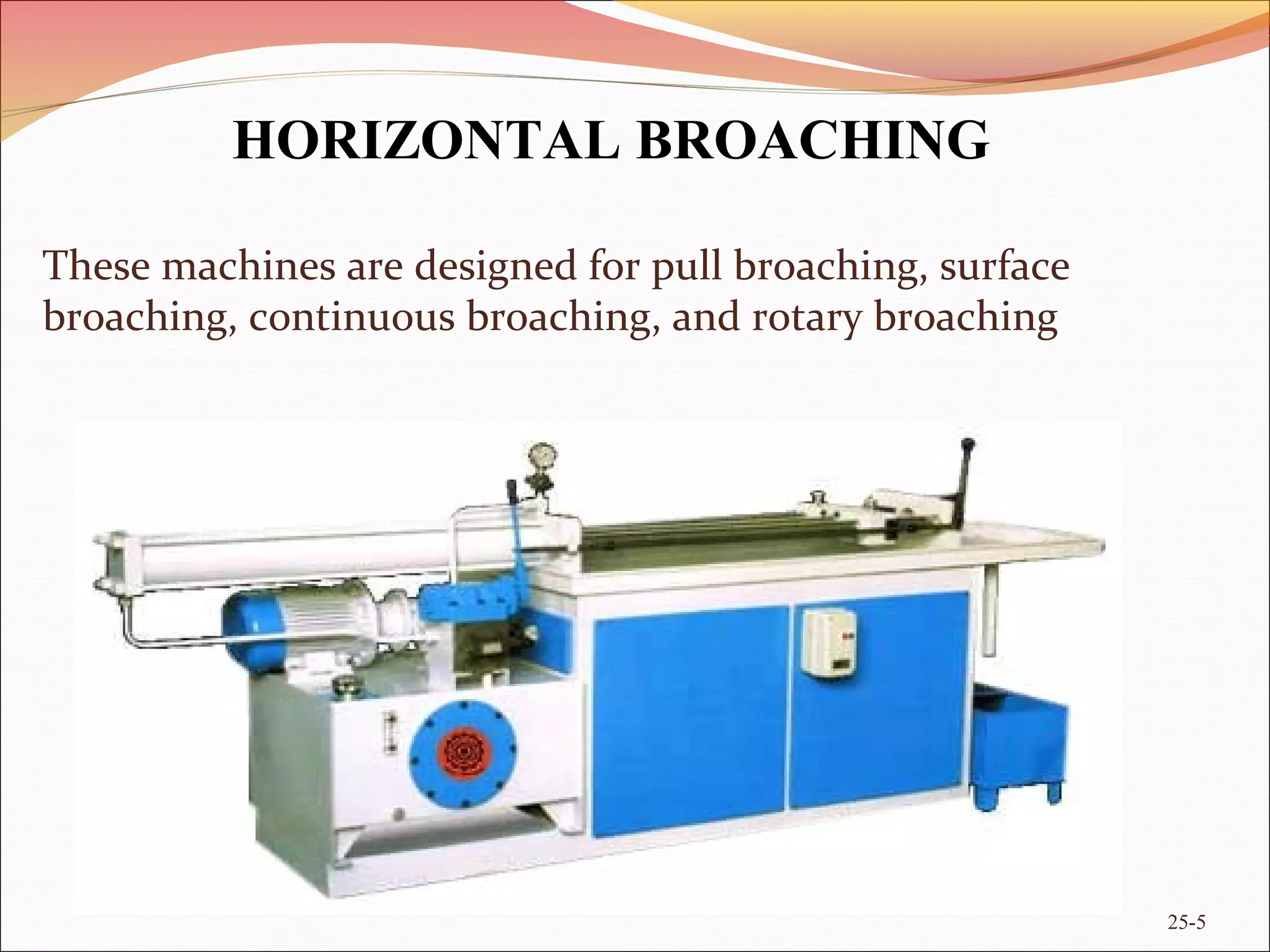

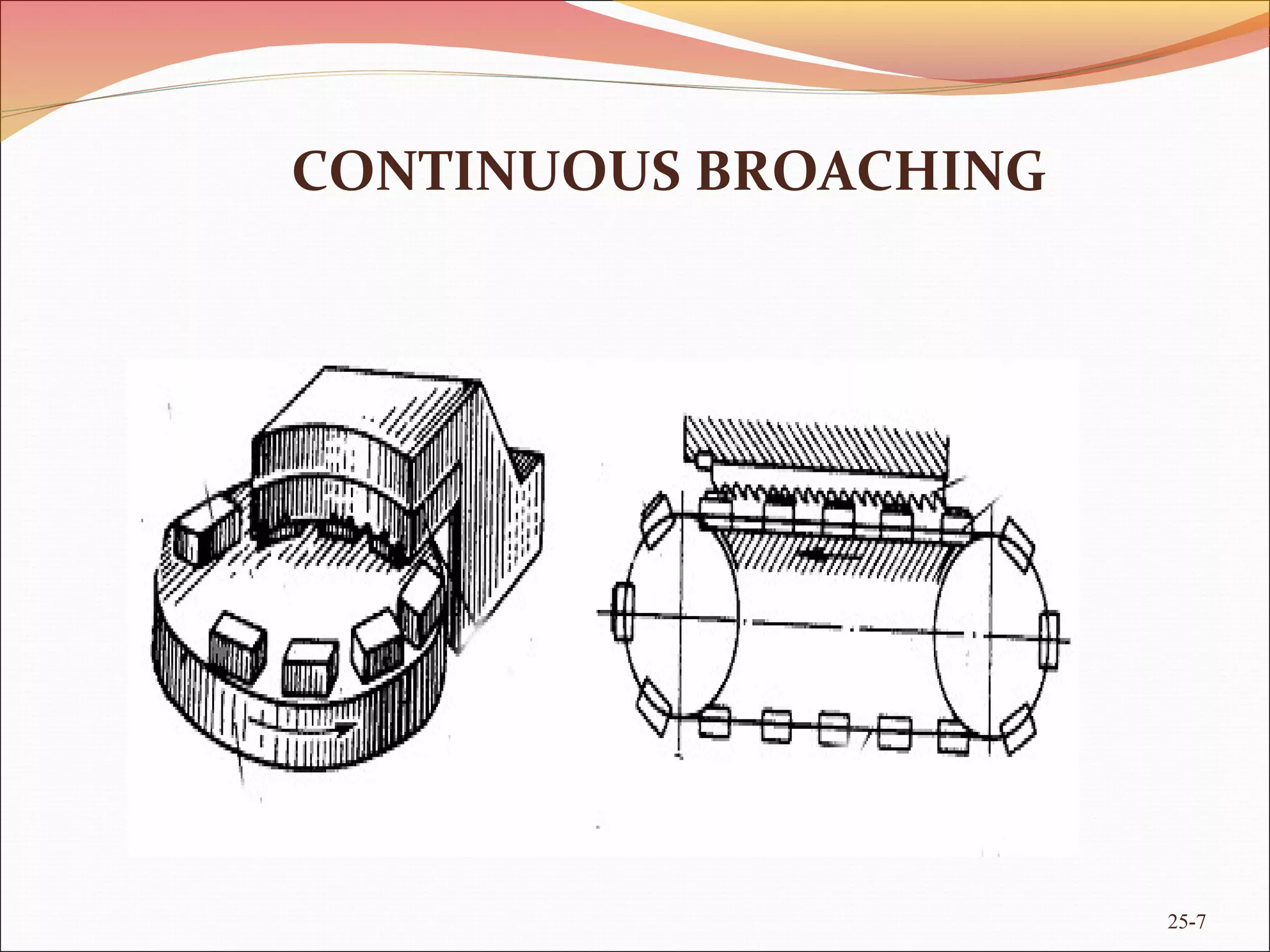

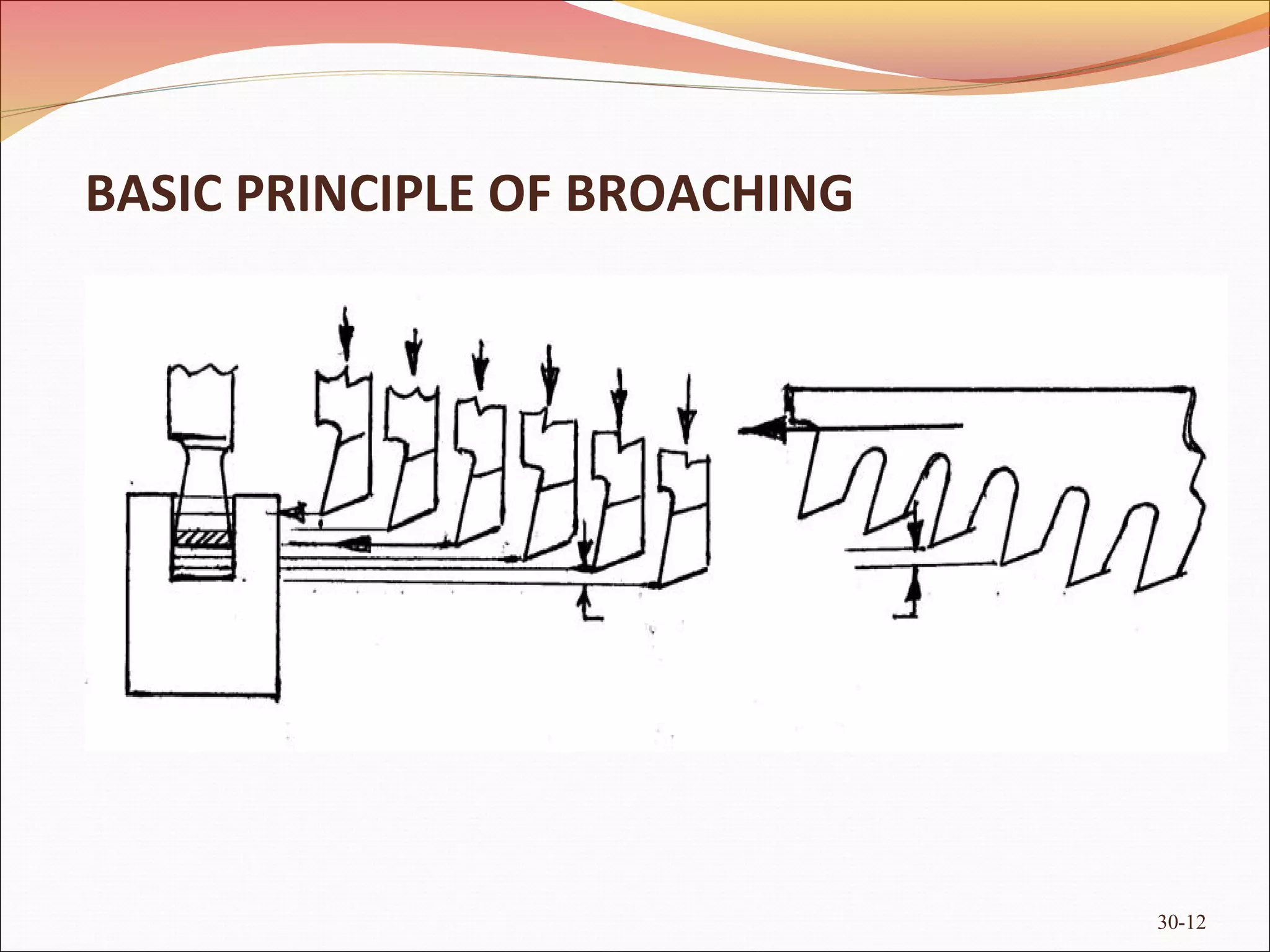

Broaching is a machining process that uses a toothed tool called a broach to remove material in a single pass. Broaching was first used in the 1850s and was commonly used to rifle gun barrels during World War 1. Broaching machines can perform horizontal, vertical, continuous, and rotary broaching. Broaching tools are designed based on the material, size and shape of the cut, required tolerances, and production rates. Broaching provides high production rates and accuracy for complex hole shapes and surfaces.

![CUTTING FORCE VARIATIONS

30-18

FMAX[kg]=a[mm2

]*re[KG/MM

2]*

n

Where

a=areaofmaterialrequired.

re=specificresistanceofcutting.

n=numberofcuttingteethsimultaneously.

n=l/p

Where](https://image.slidesharecdn.com/pptonbroachingvirendrarathore-170209145541/75/Ppt-on-broaching-18-2048.jpg)