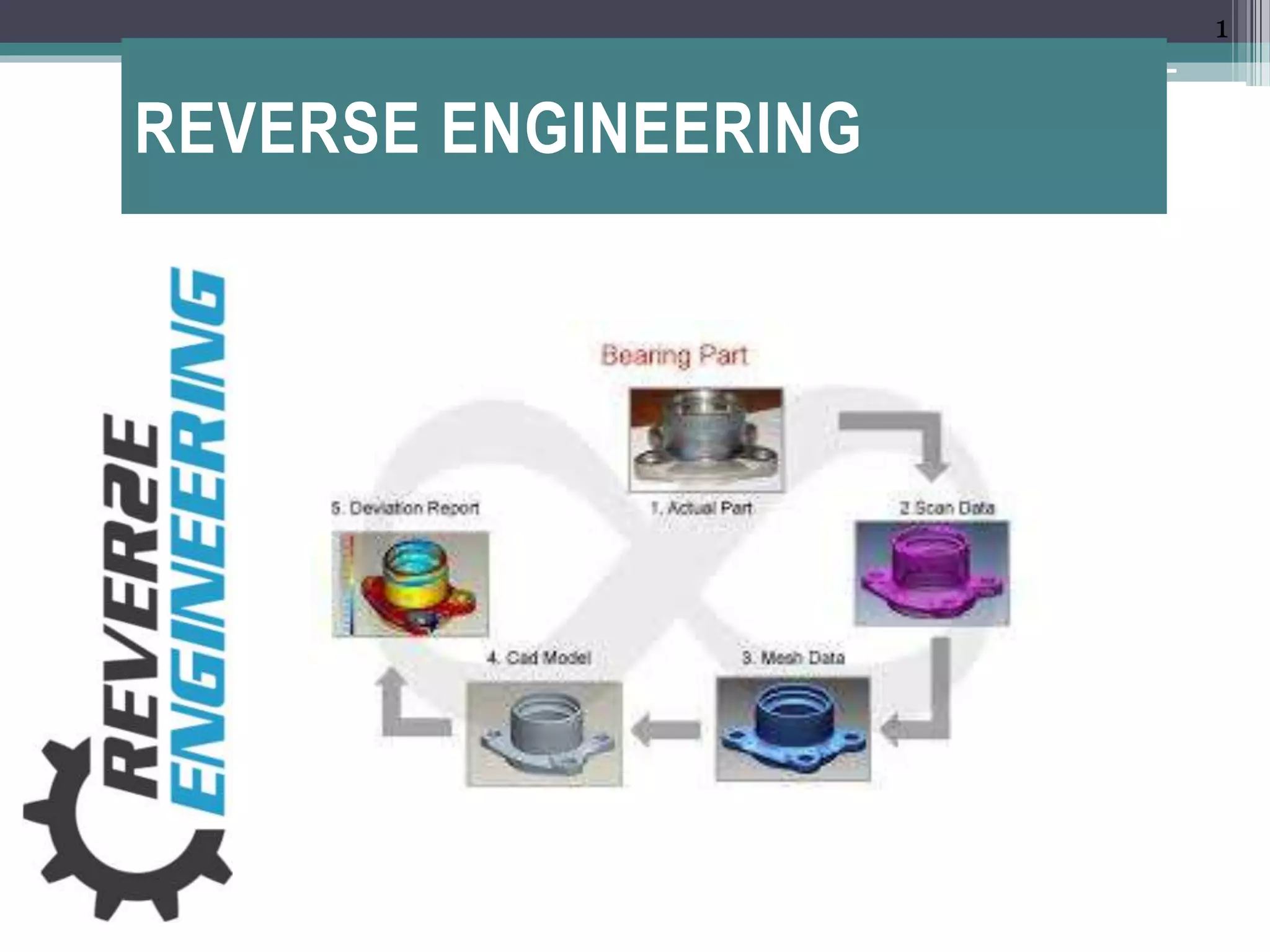

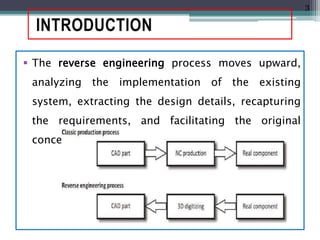

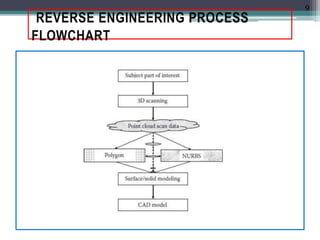

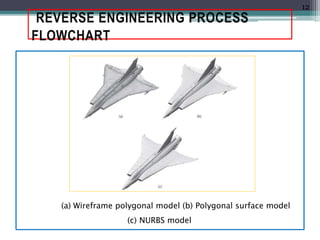

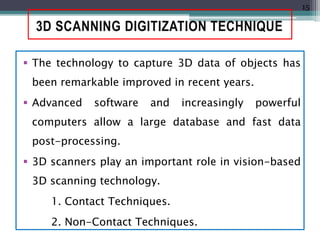

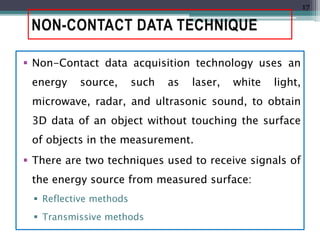

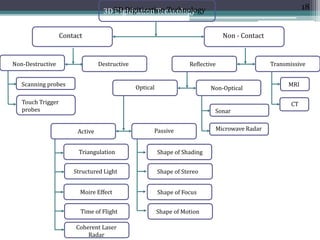

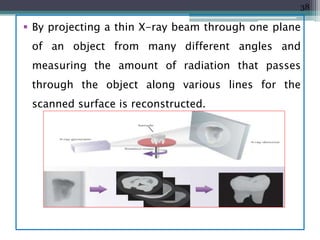

Reverse engineering is the process of analyzing an existing system or product to identify its components and design in order to extract design details without prior documentation. It involves digitizing a physical object using 3D scanning techniques like contact methods, non-contact active methods, and non-contact passive methods to obtain point cloud data. This point cloud data is then processed to generate CAD models through techniques like polygonization and refinement. The final CAD models can then be used for applications like redesign, quality control, and rapid prototyping.