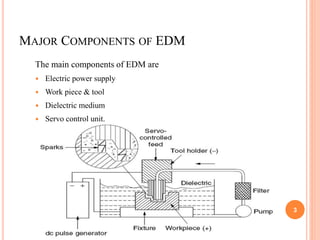

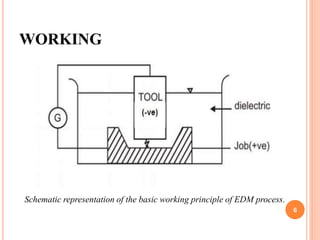

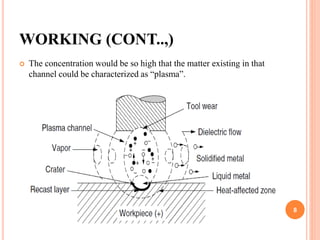

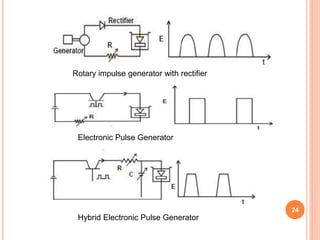

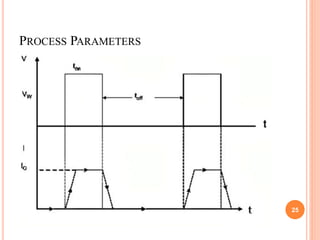

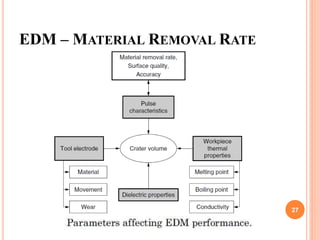

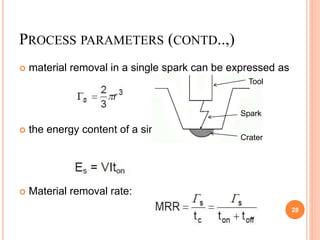

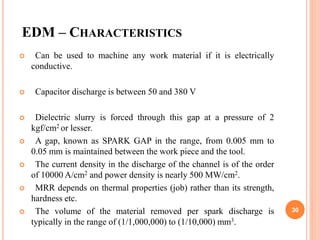

The material removal in EDM occurs due to the formation and collapse of plasma channels between the tool and workpiece. When a potential difference is applied, electrons are emitted from the tool and strike the workpiece, generating heat and forming craters. The main components of an EDM system are a power supply, workpiece and tool made of conductive materials, a dielectric medium like kerosene or water, and a servo control unit. Process parameters like voltage, current, pulse duration, and spark gap influence the material removal rate and surface finish. EDM can machine hard metals and complex shapes that other methods have difficulty with.