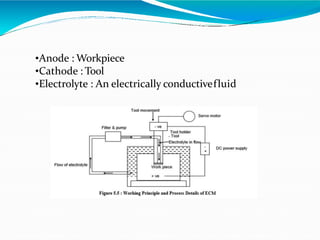

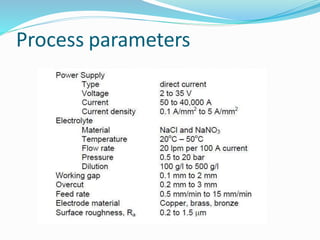

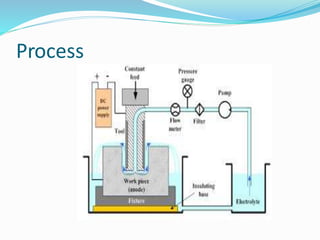

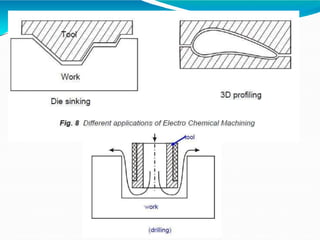

This document provides an overview of electrochemical machining (ECM). ECM is a non-conventional machining process that removes metal through an electrochemical process rather than adding it, as in electroplating. In ECM, a tool acts as the cathode and the workpiece the anode, with an electrolyte solution flowing between them. Metal is removed from the workpiece through an electrolysis process governed by Faraday's laws of electrolysis. ECM can machine complex internal and external geometries in hard metals and is well-suited for mass production. Key aspects of ECM covered include the power supply, electrolyte, tool, control system, and principles of operation. Applications and advantages, such as little