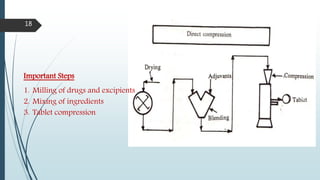

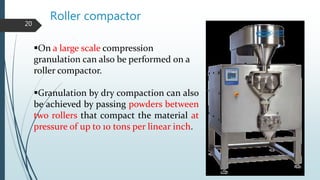

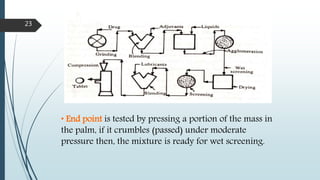

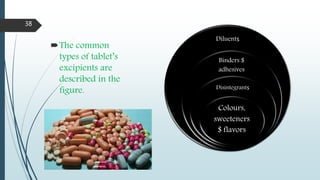

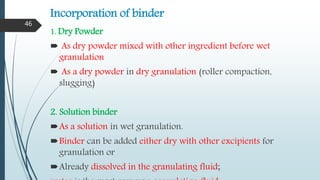

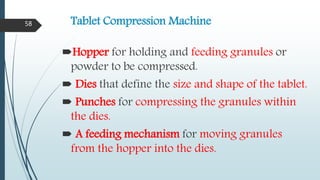

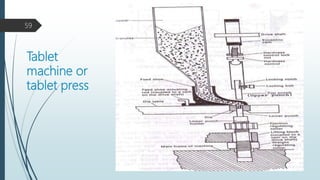

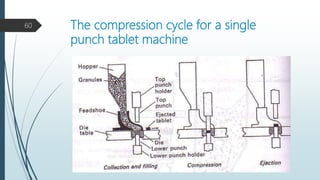

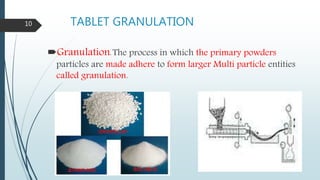

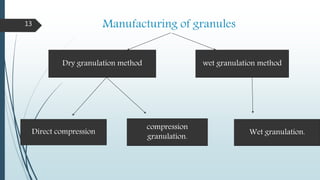

This document provides information about tablets, including their formulation, design, manufacturing, types, advantages, and excipients. Tablets are solid oral dosage forms made by compressing powder mixtures into various shapes. They have advantages like precise dosing and ease of production. The document discusses different granulation and compression methods used in tablet manufacturing. It also describes common excipients like diluents, binders, disintegrants, lubricants and their functions in tablets.

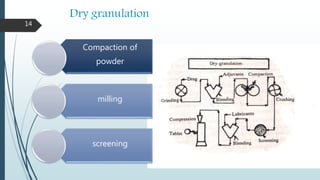

![Drug

Excipients

Diluents

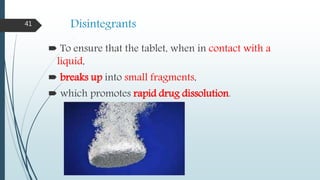

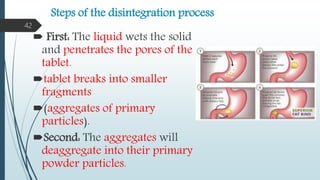

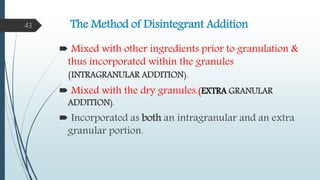

Disintegrant

Large sized tablets

Slugs

Granules

Disintegrant

Glidant

Lubricant

tablets

Compression

granulation

17

Weighing

Mixing [blender]

Slugging[tablet press,

roller compactor.

Screening sieve[20-25]

Mixing

Compression [tablet

press]](https://image.slidesharecdn.com/tabletsformulation-170202061350/85/Tablets-formulation-17-320.jpg)