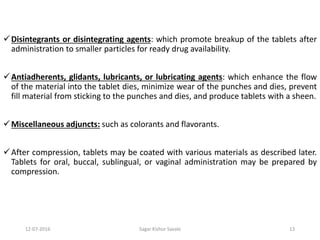

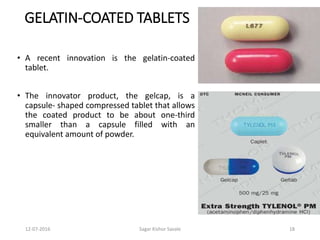

This document provides information about tablets, including their definition, advantages, types, and manufacturing process. It begins with definitions of tablets from pharmacopoeias and discusses how they are the most popular dosage form, comprising 70% of pharmaceutical preparations. It describes various types of tablets including compressed, sugar-coated, film-coated, enteric-coated, and effervescent tablets. The document outlines the tablet manufacturing process using tableting machines and discusses characteristics and specifications of compressed tablets.

![TABLETS

Mr. Sagar Kishor Savale

[Department of Pharmaceutics]

avengersagar16@gmail.com

2015 - 016

Department of Pharmacy (Pharmaceutics) | Sagar savale

112-07-2016 Sagar Kishor Savale](https://image.slidesharecdn.com/tablets-160712094157/85/Tablets-1-320.jpg)

![Considerations

Theoretical quantity of API [100% assay (anhydrous) and nil water] = 30 Kg

22212-07-2016 Sagar Kishor Savale](https://image.slidesharecdn.com/tablets-160712094157/85/Tablets-222-320.jpg)

![12-07-2016 Sagar Kishor Savale 259

Recent Advances in Granulation Techniques

• Steam Granulation: Modification of wet granulation; steam

is used as a binder instead of water; granules are more

spherical and exhibit higher rate of dissolution

• Melt Granulation / Thermoplastic Granulation: Granulation

is achieved by the addition of meltable binder i.e. binder is in

solid state at room temperature but melts in the

temperature range of 50 – 80˚C [e.g. PEG (water soluble),

stearic acid, cetyl or stearyl alcohol (water insoluble)] -

drying phase unnecessary since dried granules are obtained

by cooling them to room temperature

• Moisture Activated Dry Granulation (MADG): Involves

distribution of moisture to induce agglomeration – drying

time is reduced](https://image.slidesharecdn.com/tablets-160712094157/85/Tablets-259-320.jpg)