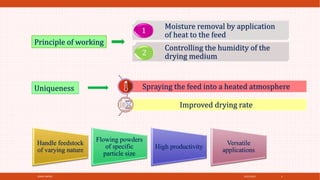

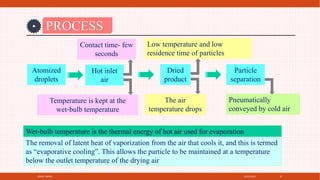

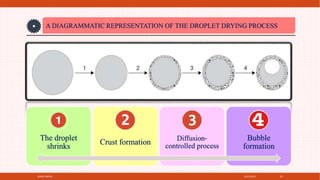

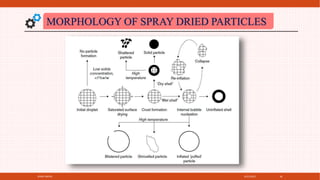

1) Spray drying is a process that transforms liquids into dry powder form by spraying the liquid into a hot drying gas. It involves atomizing the liquid, contacting the spray with hot air, evaporating moisture from the droplets, and separating the solid particles.

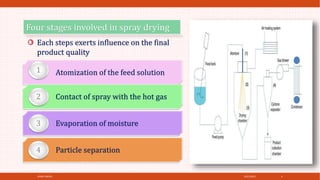

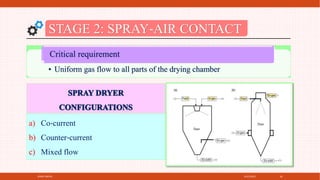

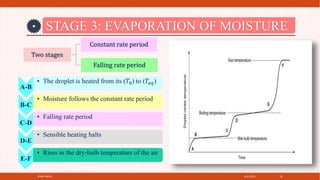

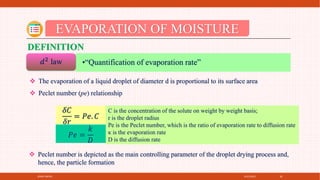

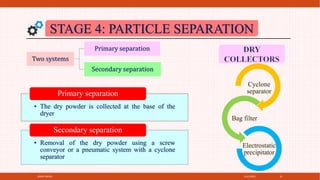

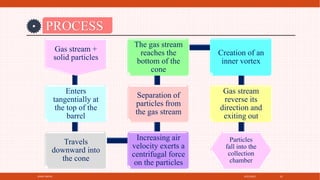

2) There are four main stages in spray drying: atomization of the liquid, contact between the spray and drying air, evaporation of moisture from the droplets, and separation of solid particles from the air stream.

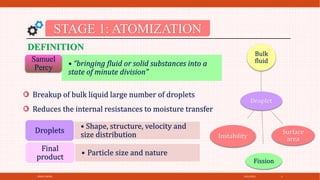

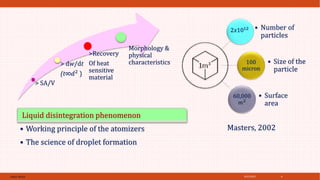

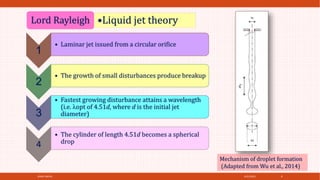

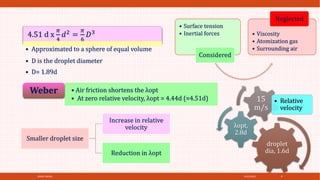

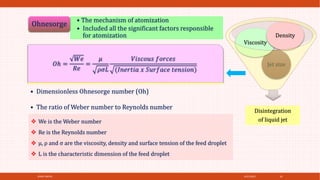

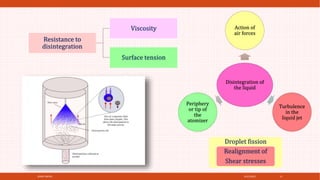

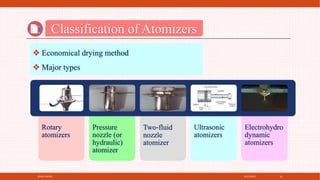

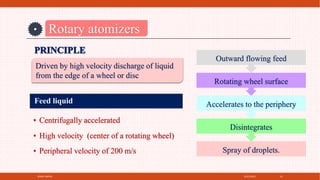

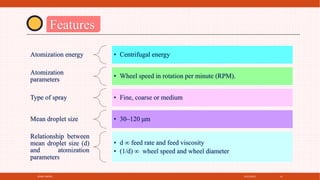

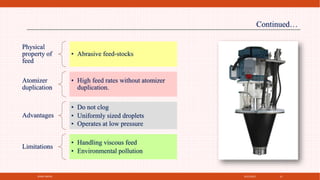

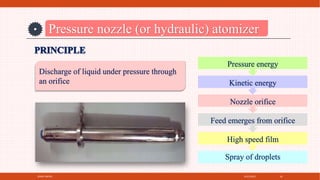

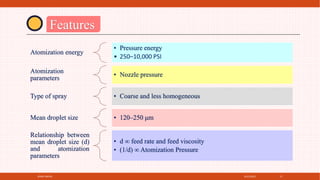

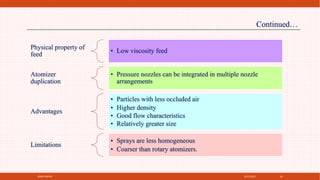

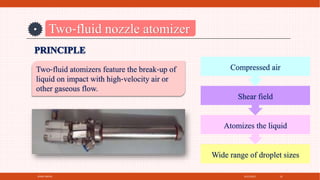

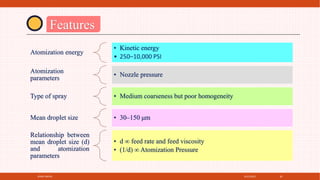

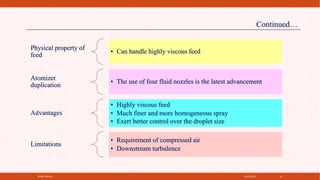

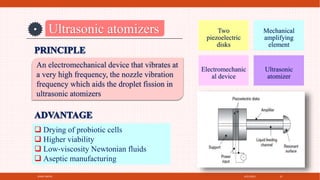

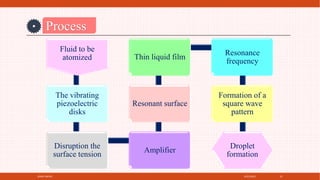

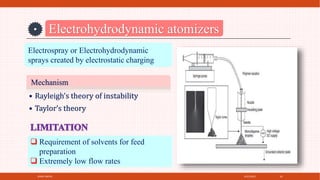

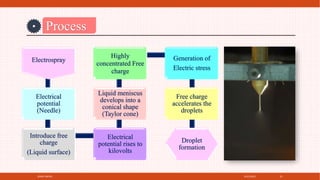

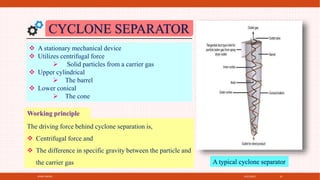

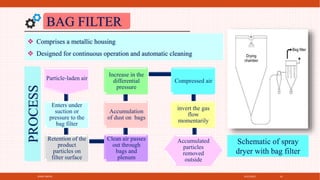

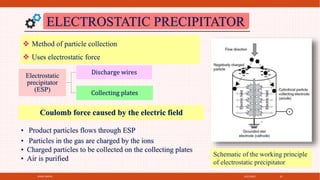

3) Atomization methods include rotary atomizers, pressure nozzles, two-fluid nozzles, ultrasonic atomizers, and electrohydrodynamic atomizers. Cyclones and bag filters are commonly used for particle separation.