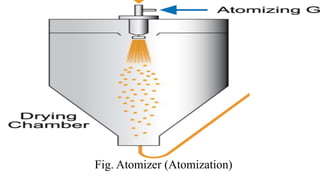

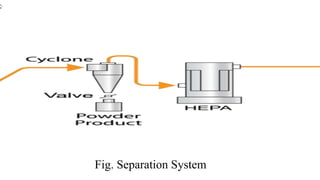

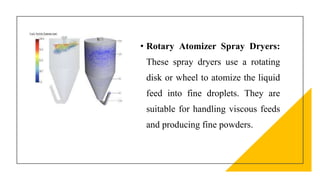

The document discusses spray drying as an essential process for transforming liquid feeds into dry powders, highlighting its historical evolution and versatile applications in food, pharmaceuticals, and chemicals. It details technical aspects such as efficiency factors, types of spray dryers, and recent advancements like computational modeling and automation integration. The conclusion emphasizes the need for continuous optimization and innovation to enhance energy efficiency and product quality in spray drying processes.