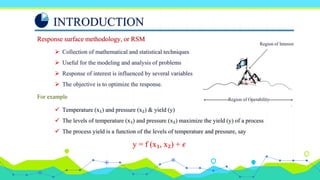

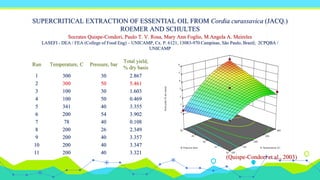

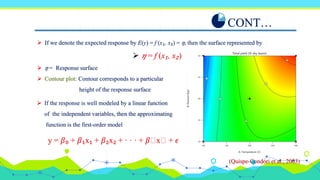

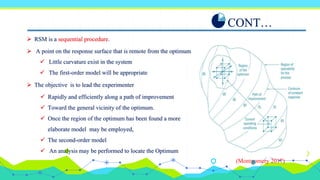

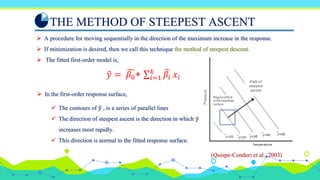

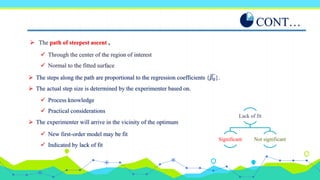

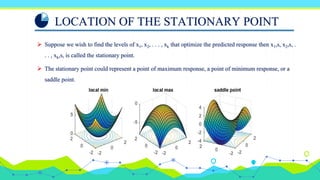

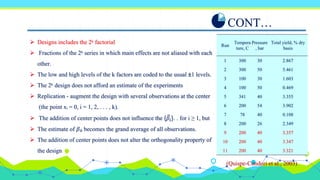

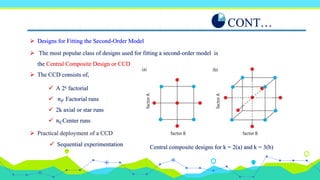

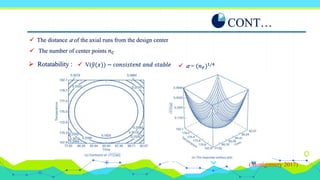

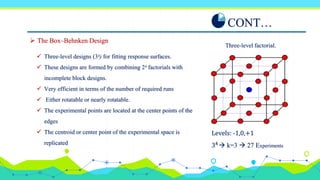

The document discusses response surface methodology (RSM), which uses statistical and mathematical techniques to model and analyze problems with responses influenced by several variables. RSM is used to optimize responses by exploring the relationships between variables and responses through designed experiments and polynomial mathematical models. Key aspects covered include first and second-order polynomial models, experimental designs like factorial and central composite designs, and techniques like steepest ascent to navigate response surfaces. Examples demonstrate how RSM can be applied to optimize process variables and responses.