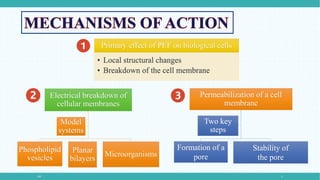

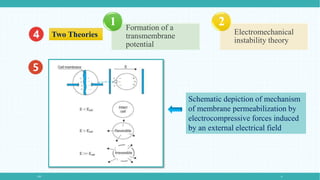

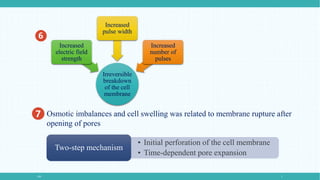

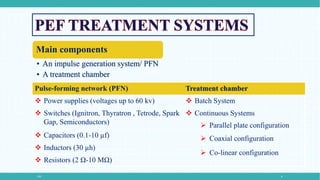

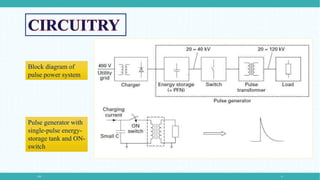

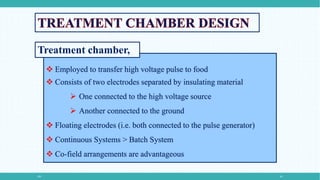

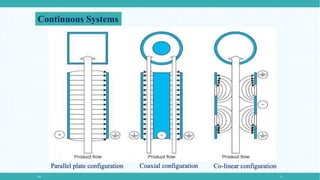

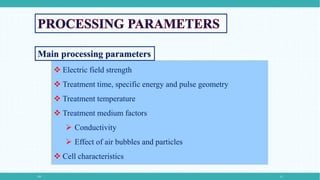

The document discusses Pulsed Electric Fields (PEF) technology as an innovative, non-thermal food processing method that efficiently inactivates microorganisms while preserving food quality. It outlines the fundamental mechanisms, treatment systems, and various applications of PEF, including its role in processing juices, dairy products, and enhancing drying efficiency. The document highlights the advantages of PEF over conventional thermal processing in maintaining sensory and nutritional values of food.