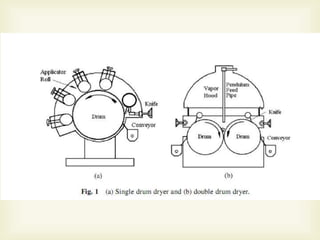

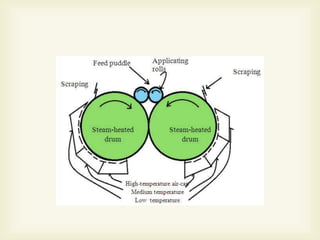

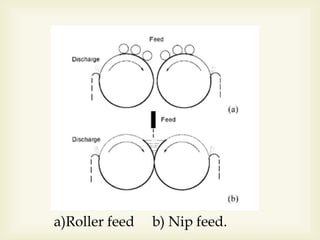

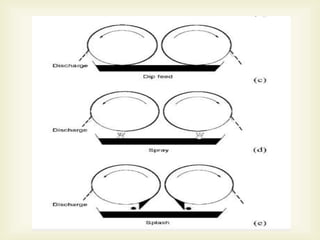

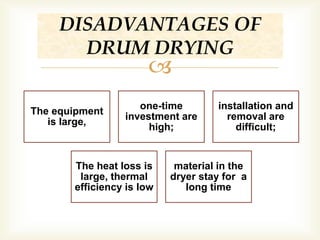

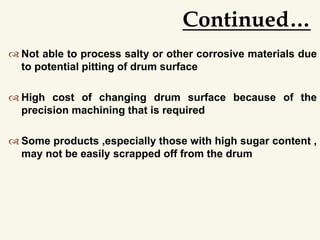

Drum dryers are indirect dryers that remove moisture from materials by spreading them in a thin film on a rotating steam-heated drum. As the drum rotates, a doctor blade scrapes the dried film off. Drum drying requires less space than spray drying and allows for continuous operation. While drum drying has advantages like large capacity and simple operation, it also has disadvantages such as high energy costs, long drying time for materials, and difficulty processing corrosive substances.