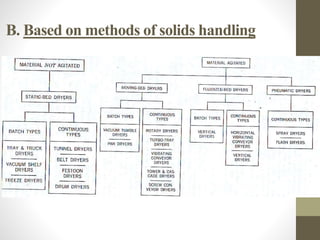

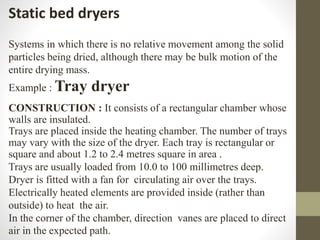

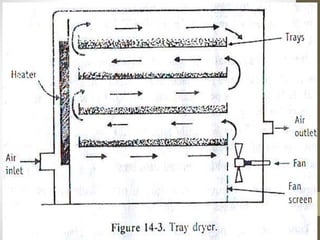

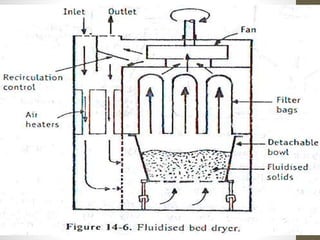

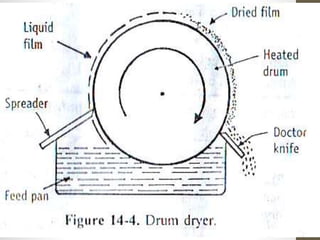

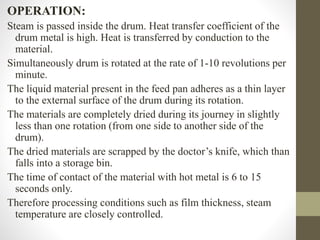

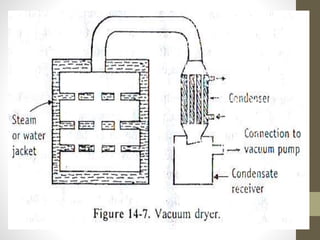

The document provides a detailed overview of various types of dryers used for drying materials, including convective, conductive, radiation, freeze drying, fluidized bed, moving bed, pneumatic, spray, and vacuum dryers. Each type is described in terms of its construction, operation, merits, and demerits, alongside specific uses for drying different materials. Additionally, it outlines important factors for preliminary dryer selection, including material properties, drying characteristics, and economic considerations.