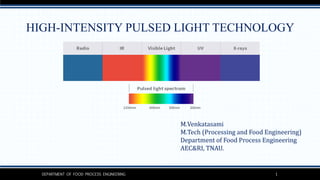

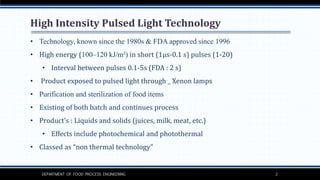

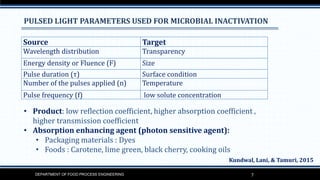

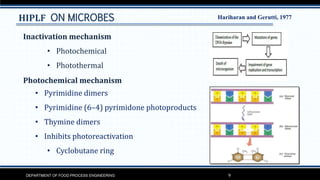

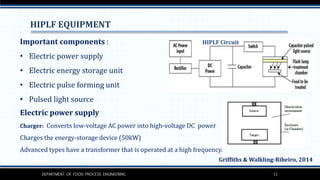

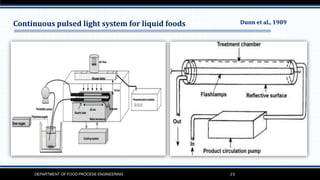

This document discusses high-intensity pulsed light technology (HIPL), a non-thermal method for sterilizing food through short pulses of intense light. It details its effects on microbial inactivation, mechanisms of action, equipment requirements, and case studies showing its efficacy on various food products without altering nutritional or sensory attributes. HIPL has potential applications for decontaminating liquids and solids while preserving food quality.