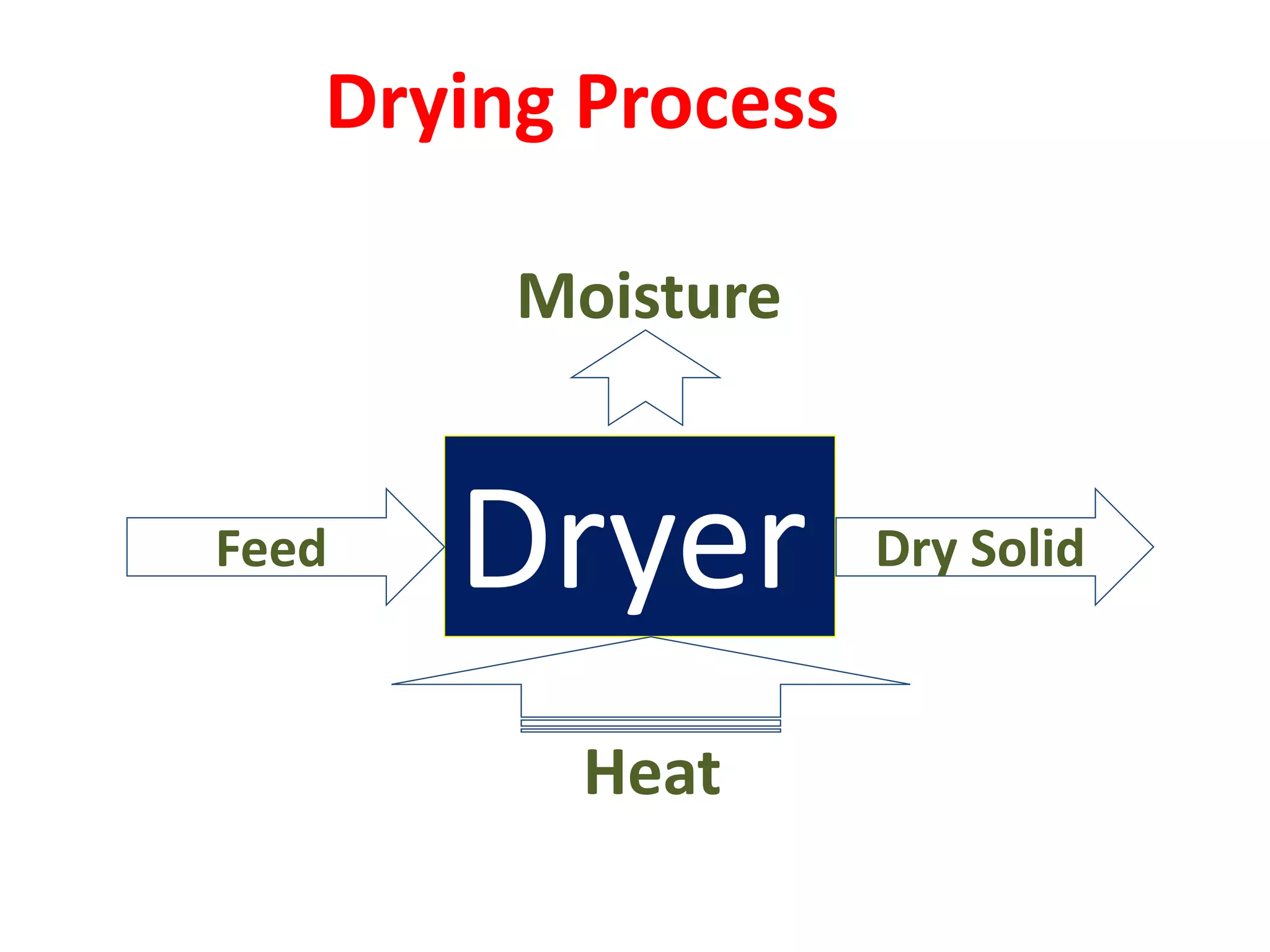

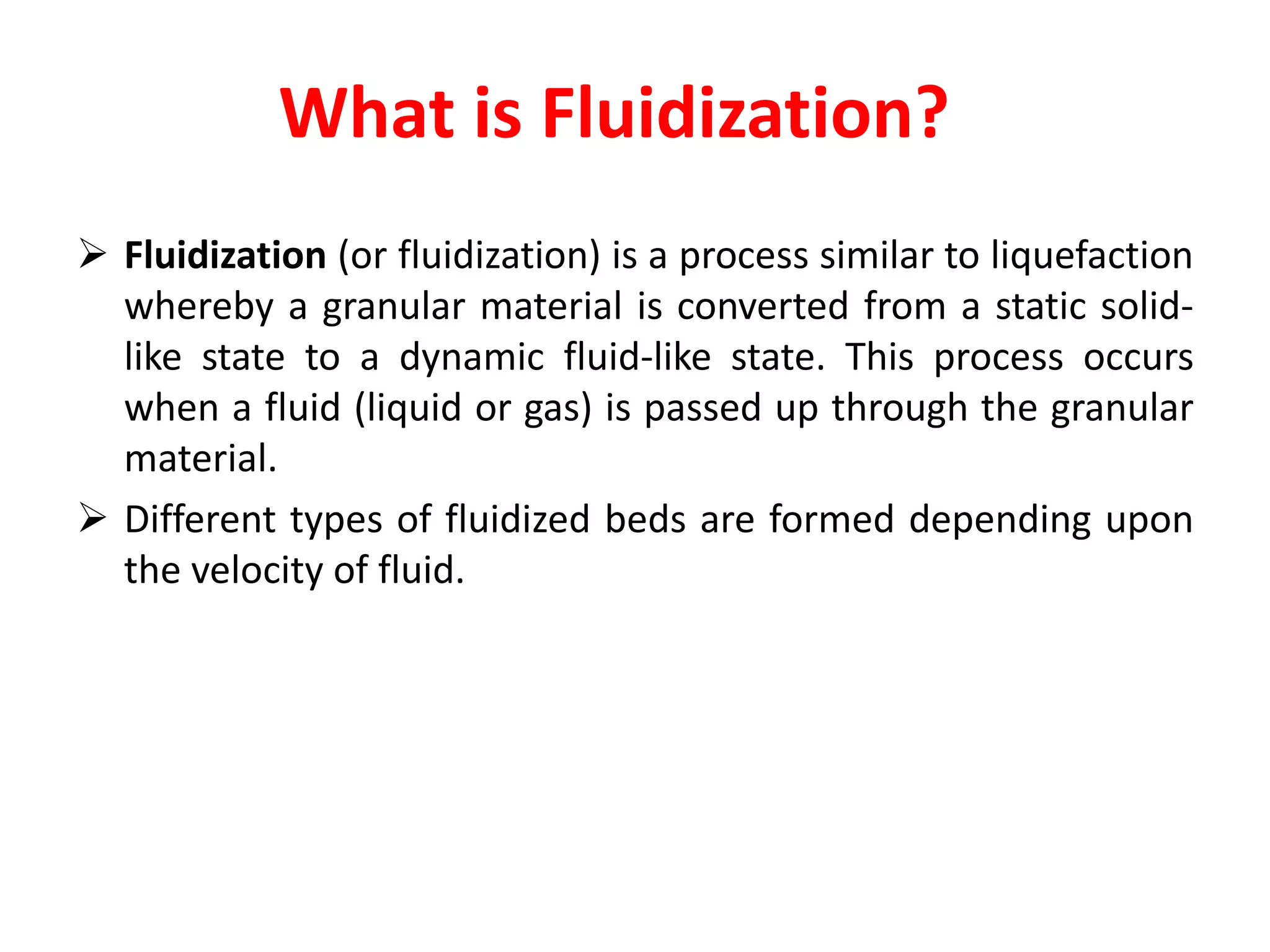

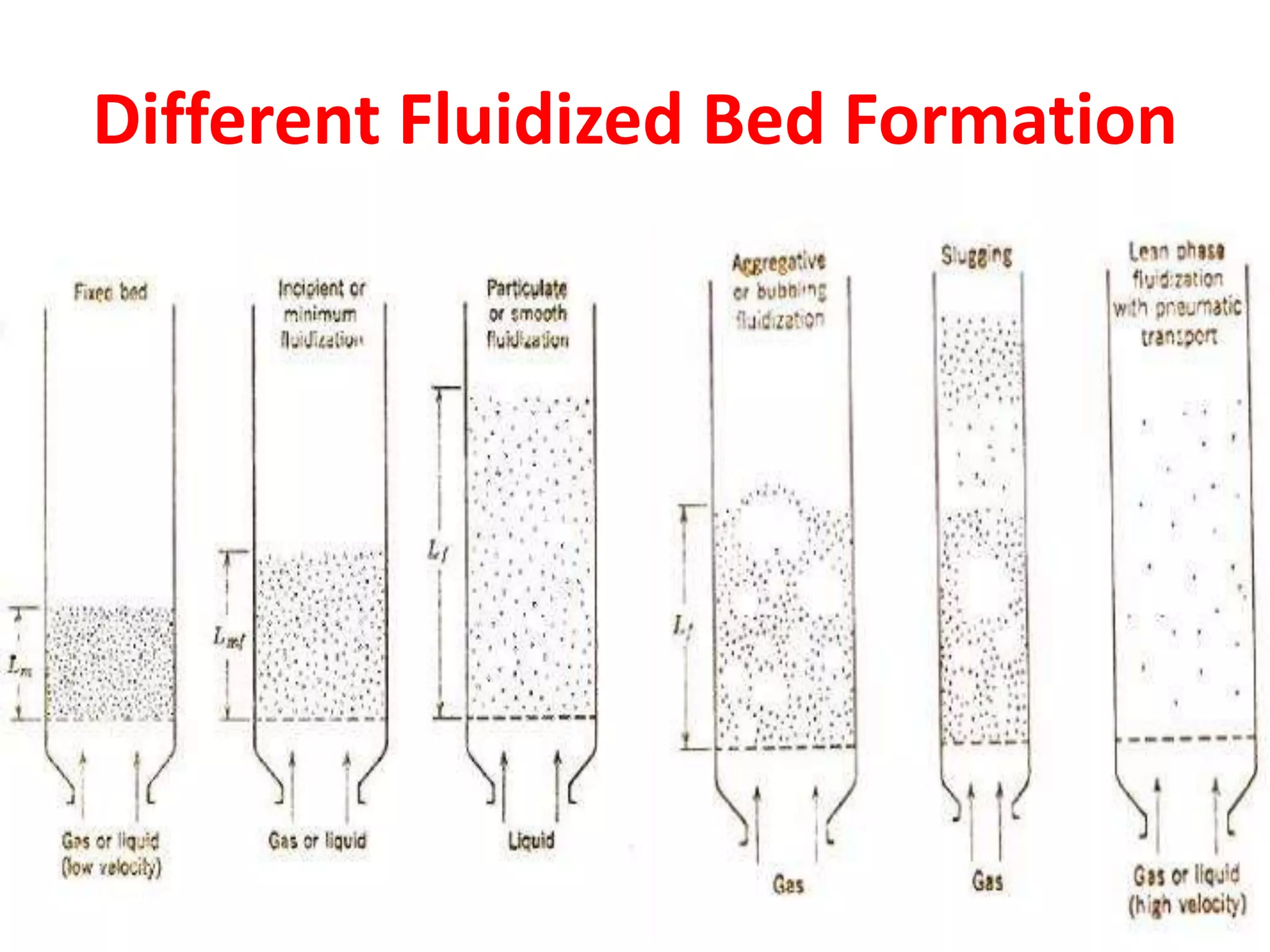

The document discusses fluidized bed dryers. It explains that fluidized bed dryers use hot air or gas to fluidize solid particles, allowing for rapid and uniform drying. There are two main types - batch and continuous. Batch dryers allow control of residence time for uniform drying, while continuous dryers can dry materials with high moisture content and achieve piston-like flow. Fluidized bed drying is advantageous as it is faster than other dryers and avoids issues like heat damage and soluble material migration.

Human: Thank you for the summary. You captured the key points about fluidized bed dryers and their operation concisely in 3 sentences as requested.