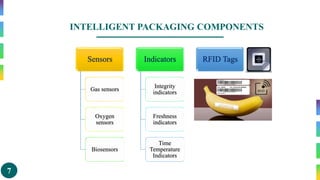

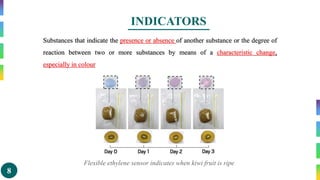

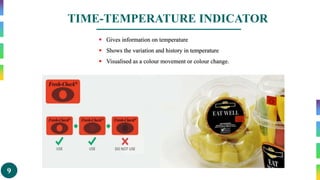

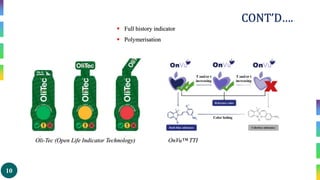

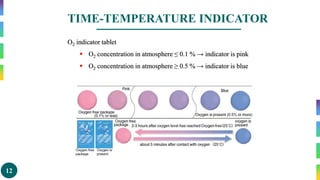

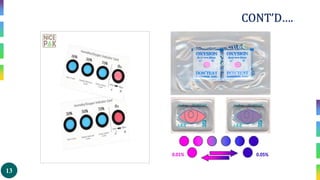

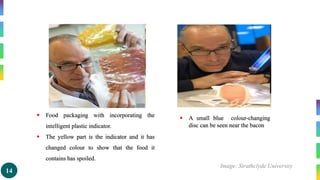

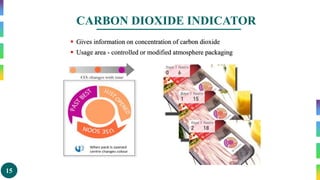

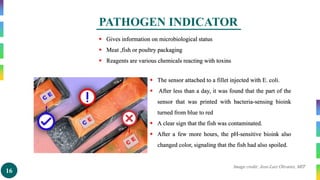

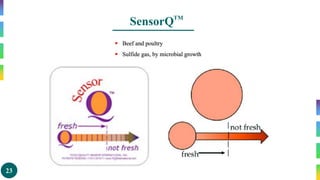

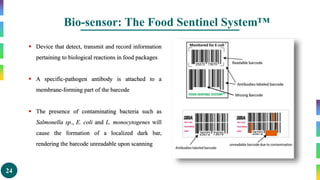

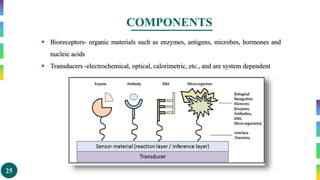

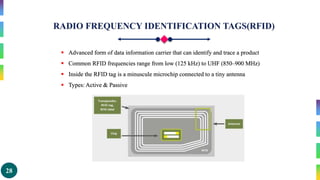

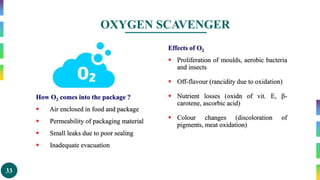

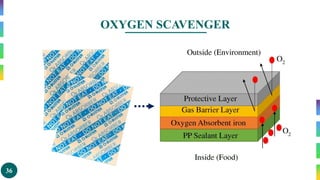

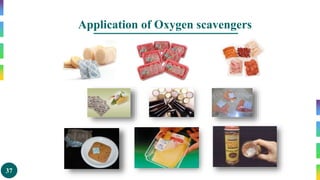

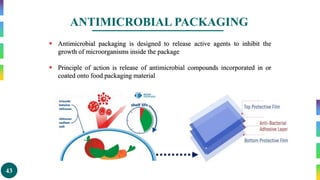

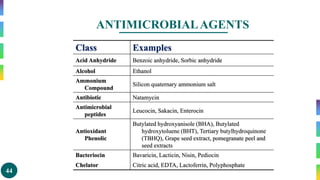

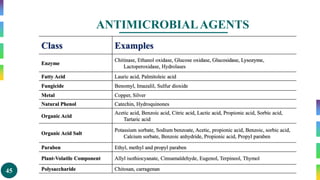

Smart and active packaging systems can incorporate sensors, indicators, and other technologies to monitor food quality and safety throughout the supply chain. Common functions of intelligent packaging include sensing oxygen, carbon dioxide, moisture, pathogens, and temperature to provide information on food freshness and detect potential issues. Key components include gas sensors, biosensors, time-temperature indicators, and RFID tags. Indicators produce a visible color change in response to chemical reactions to provide information on conditions inside the package. Active packaging technologies like oxygen scavengers and antimicrobial agents are designed to prolong shelf-life by absorbing or releasing specific gases.