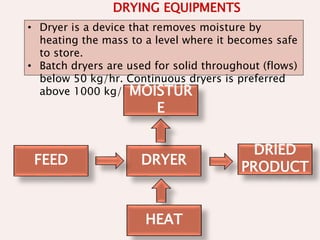

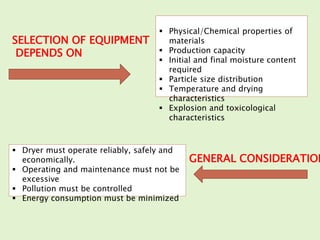

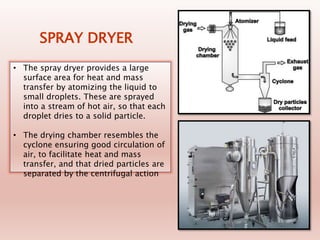

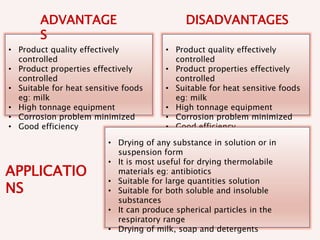

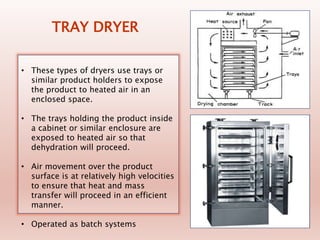

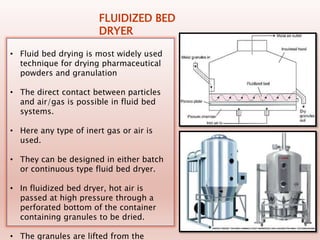

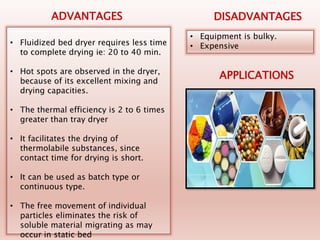

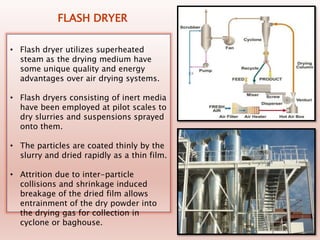

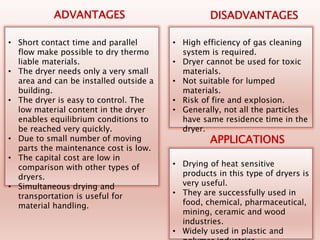

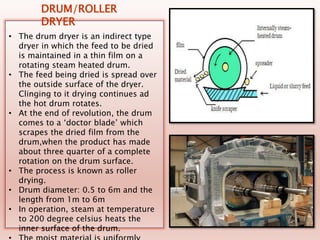

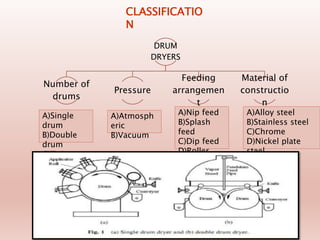

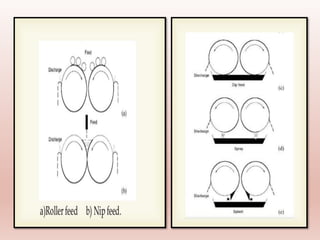

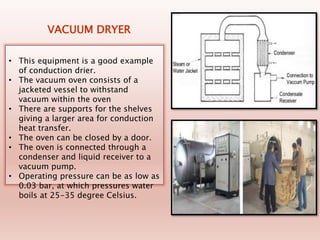

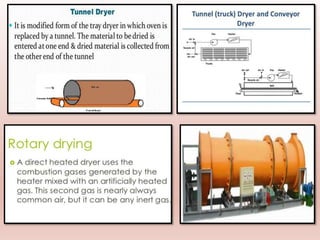

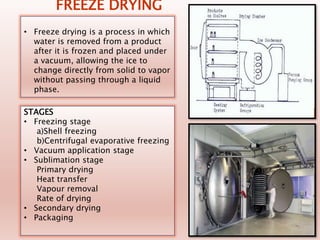

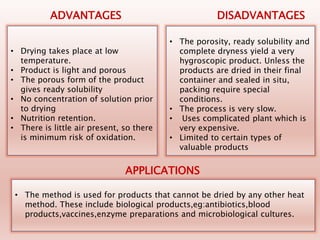

The document discusses various types of drying equipment used to remove moisture from foods and other materials. It describes common industrial dryers like spray dryers, tray dryers, fluidized bed dryers, drum dryers, vacuum dryers, and freeze dryers. For each type of dryer it provides details on how it works, advantages, disadvantages, and applications. The overall document provides an overview of key industrial drying methods and factors to consider when selecting appropriate drying equipment.