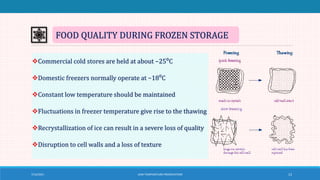

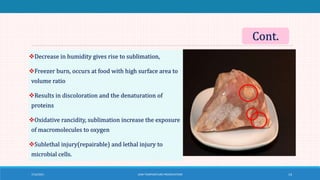

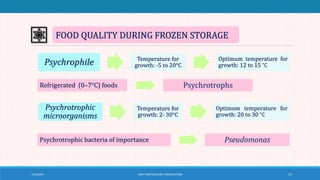

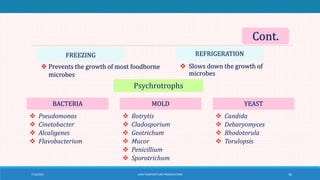

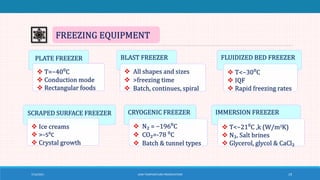

The document discusses low-temperature preservation techniques, highlighting chilling and freezing as methods to extend food shelf life by reducing spoilage and maintaining nutritional quality. It covers key aspects such as freezing rates, the influence of temperatures on food properties, and best practices to minimize quality loss during storage. Additionally, it addresses the prevention of microbial growth and outlines different types of freezing equipment.