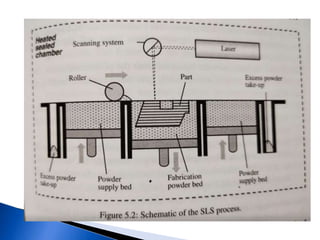

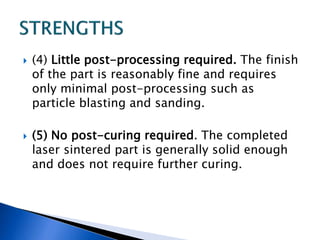

Powder-based additive manufacturing systems like selective laser sintering use a laser to fuse powdered material together to build parts layer by layer. Key systems include 3D Systems' SLS technology, which was the first to commercialize SLS and uses a CO2 laser to sinter nylon and other powders without fully melting them. The process produces strong prototypes directly from CAD data without additional supports.