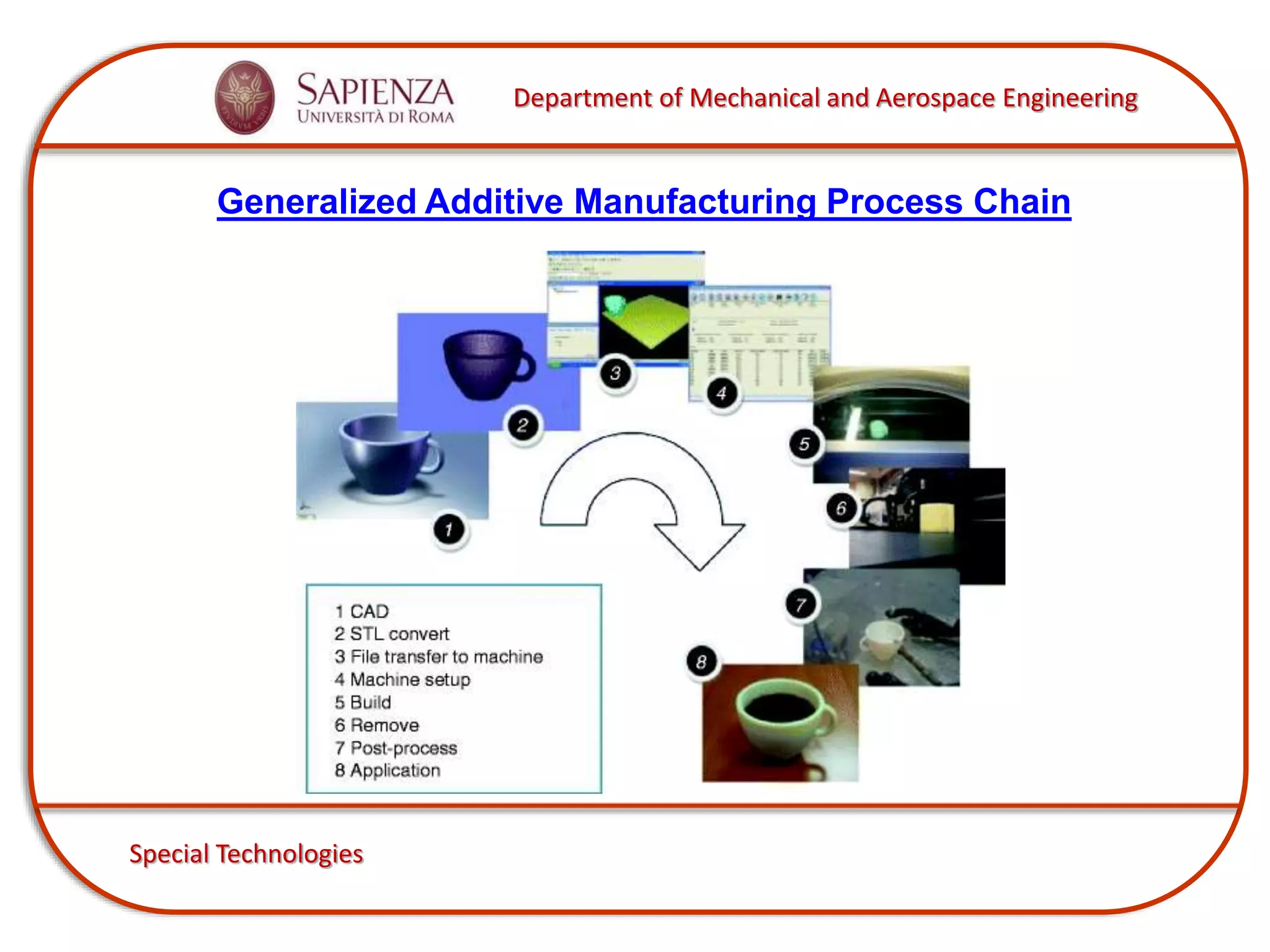

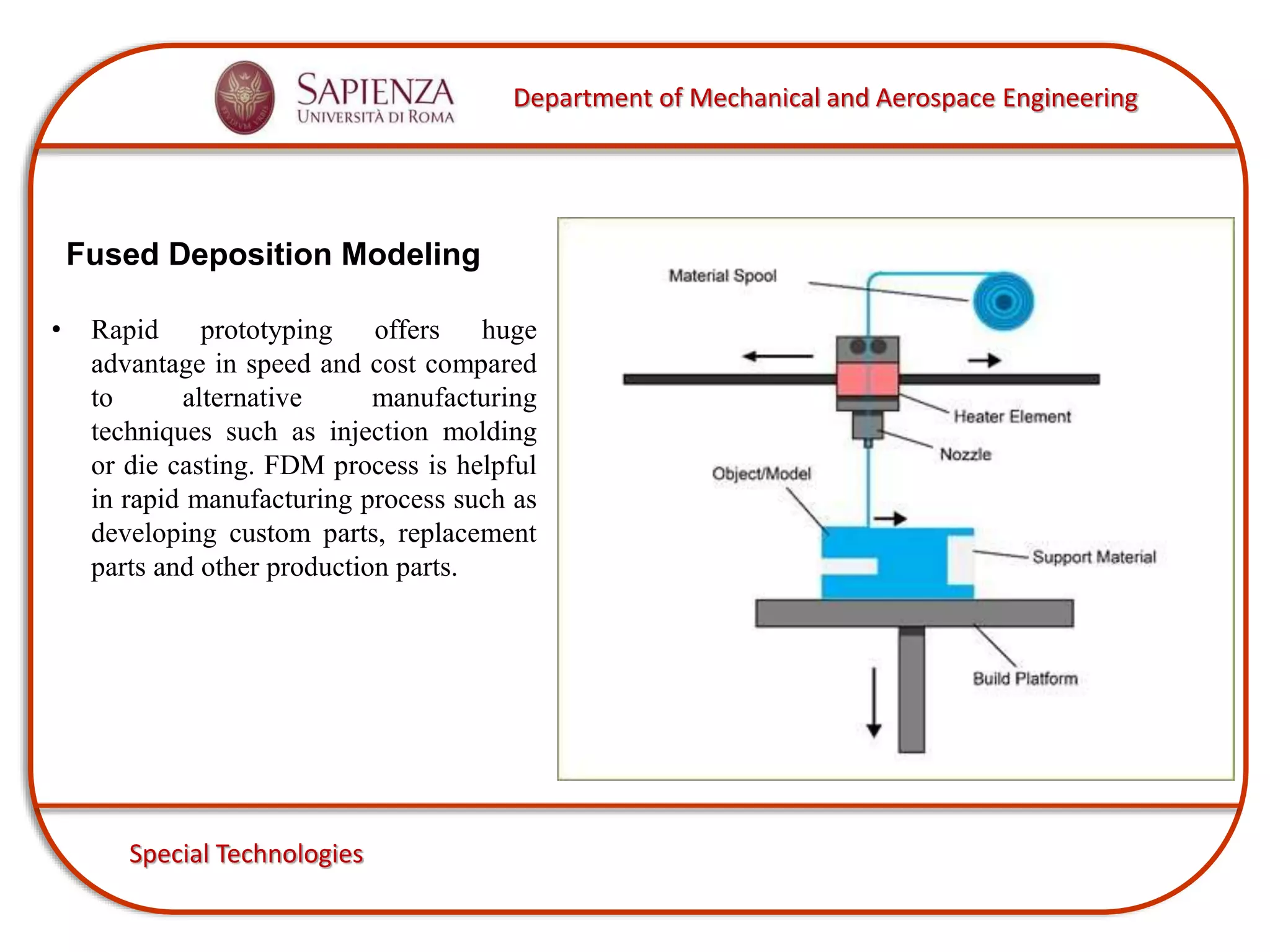

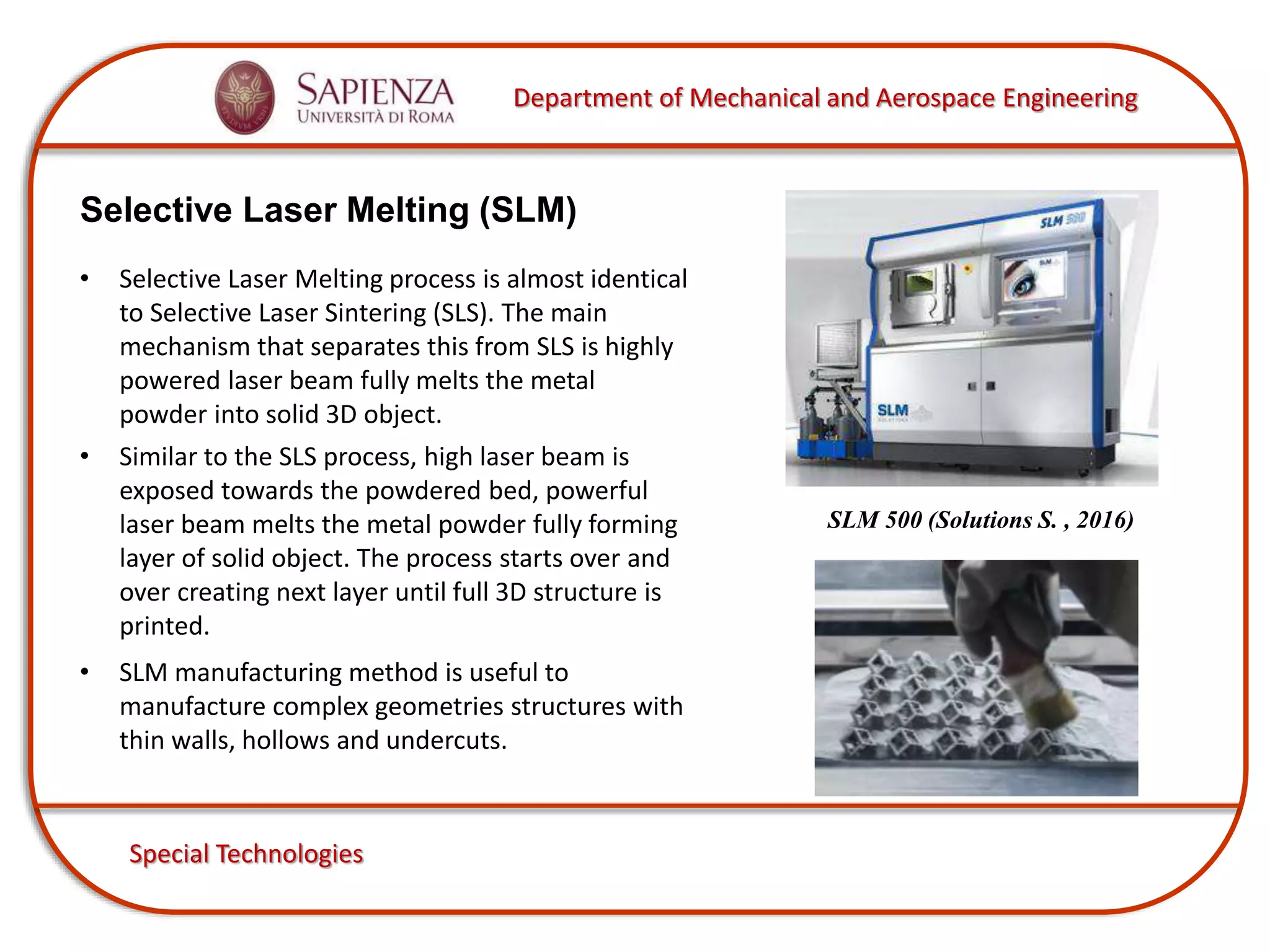

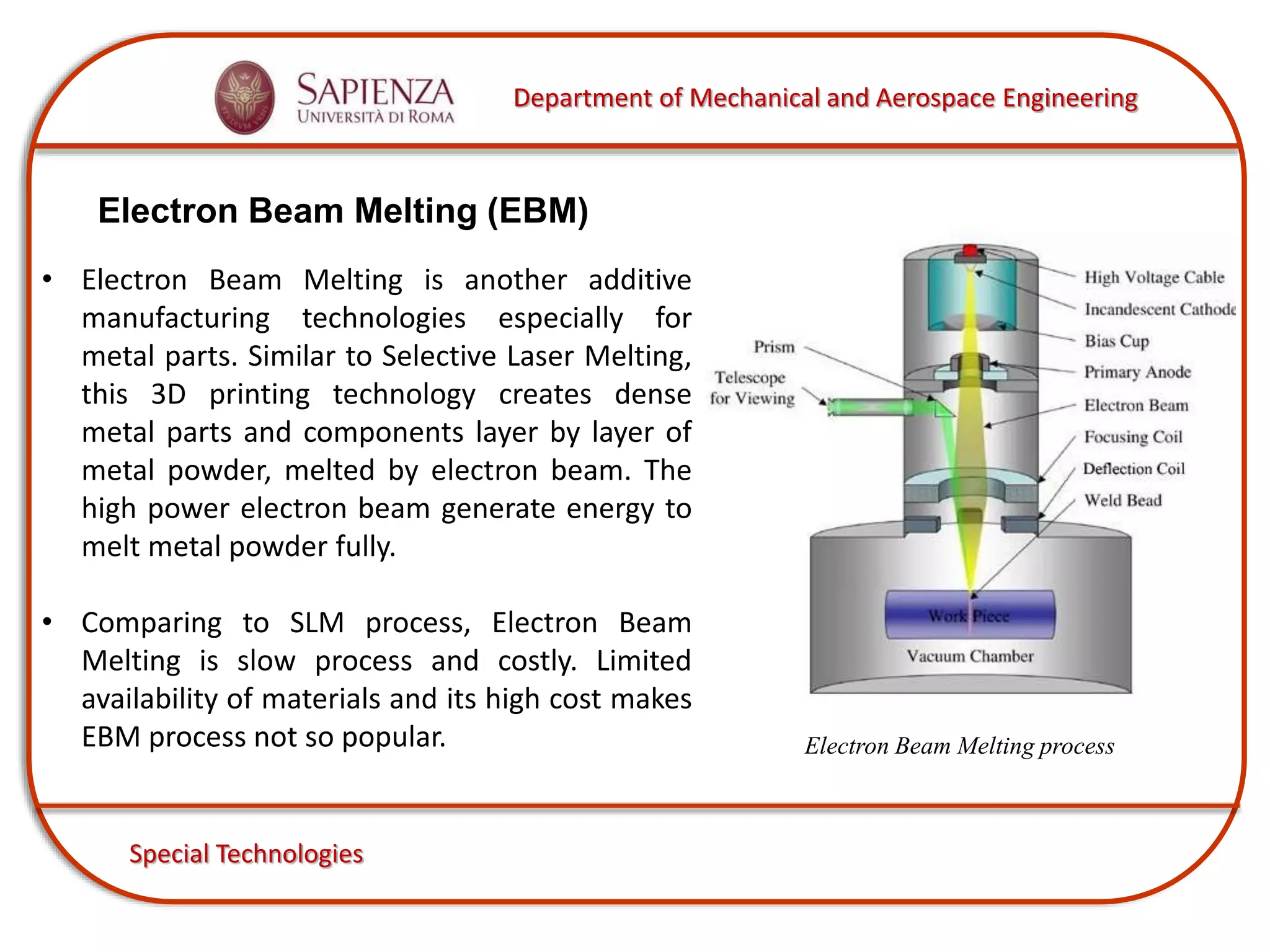

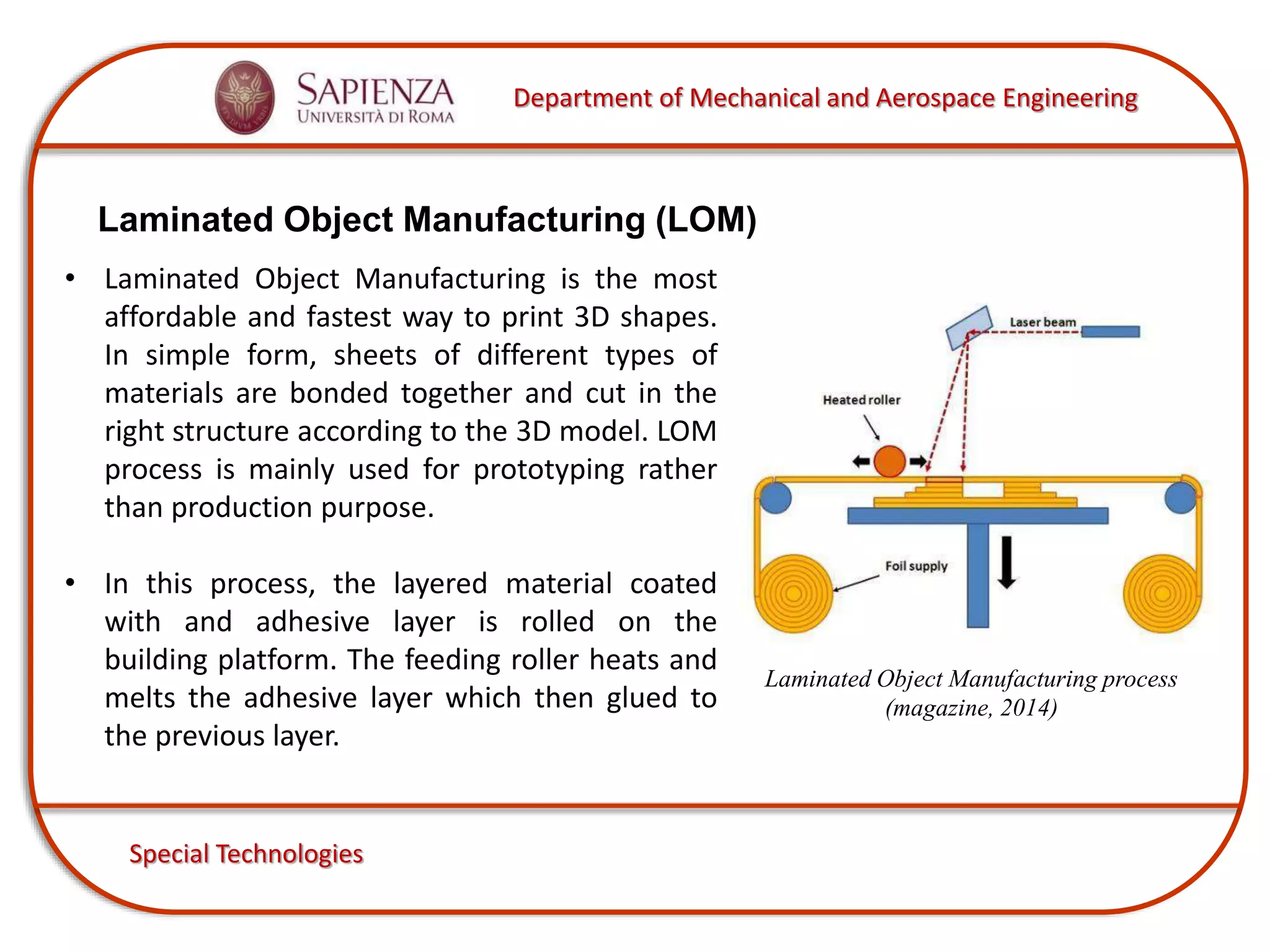

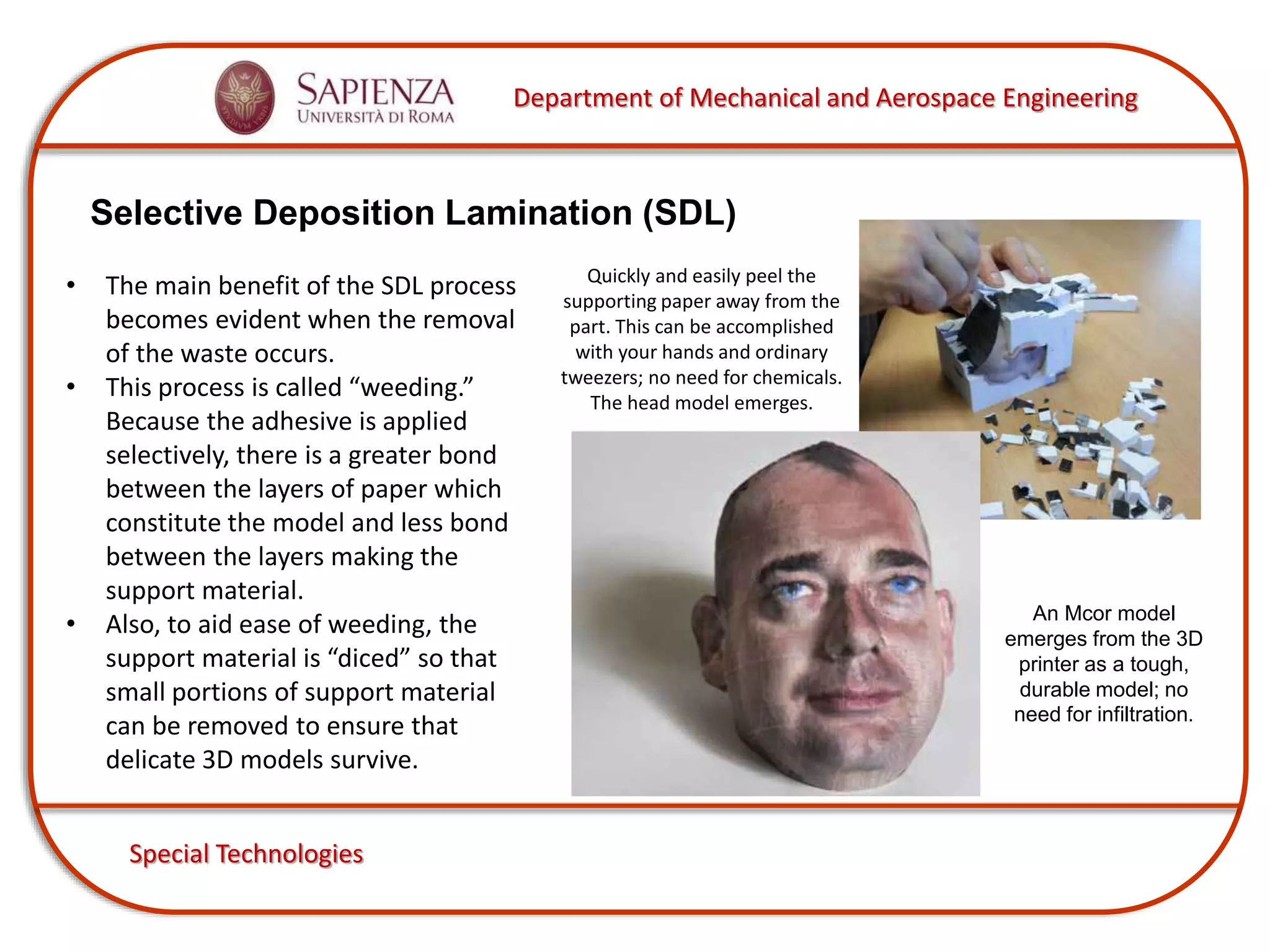

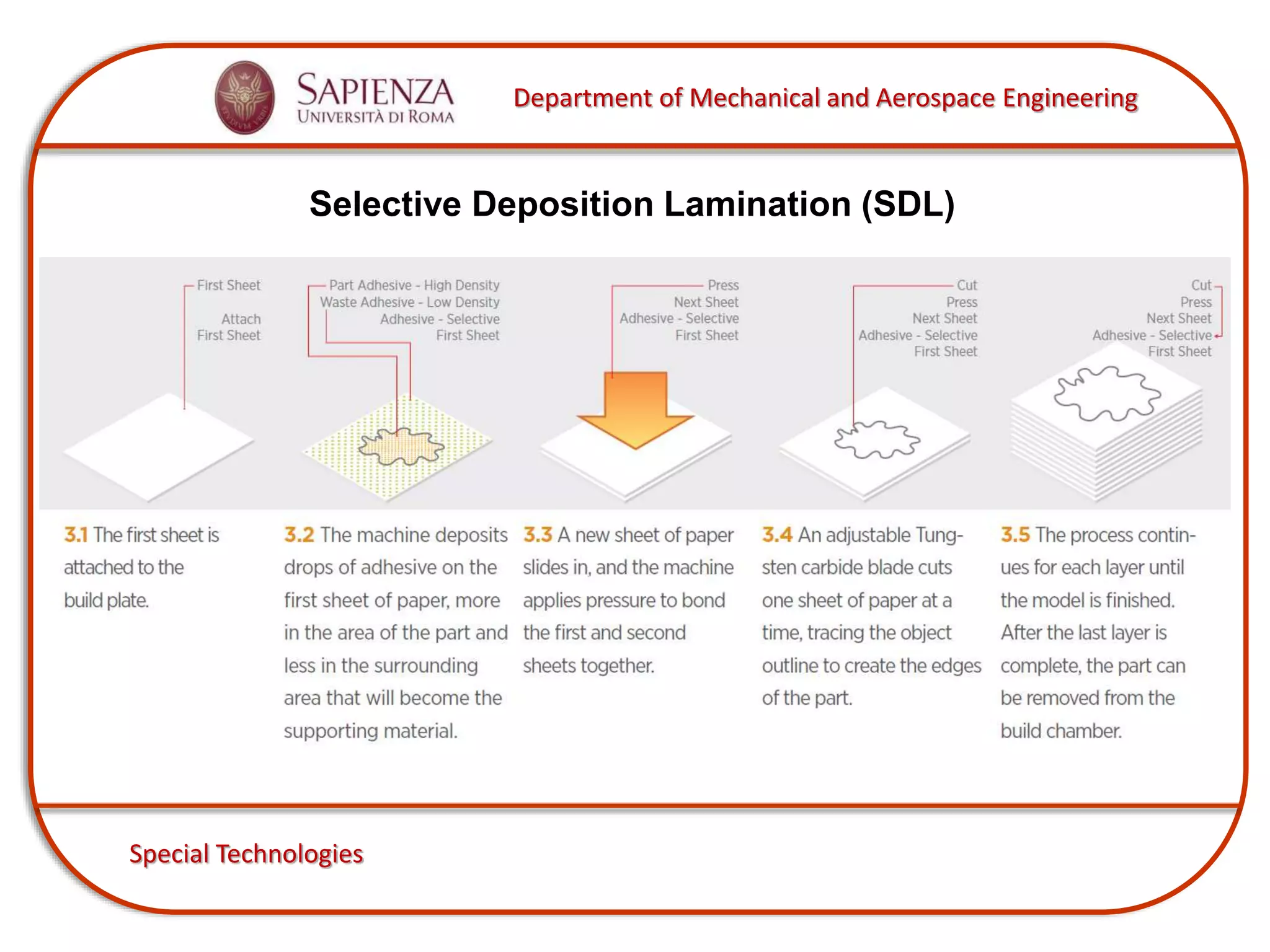

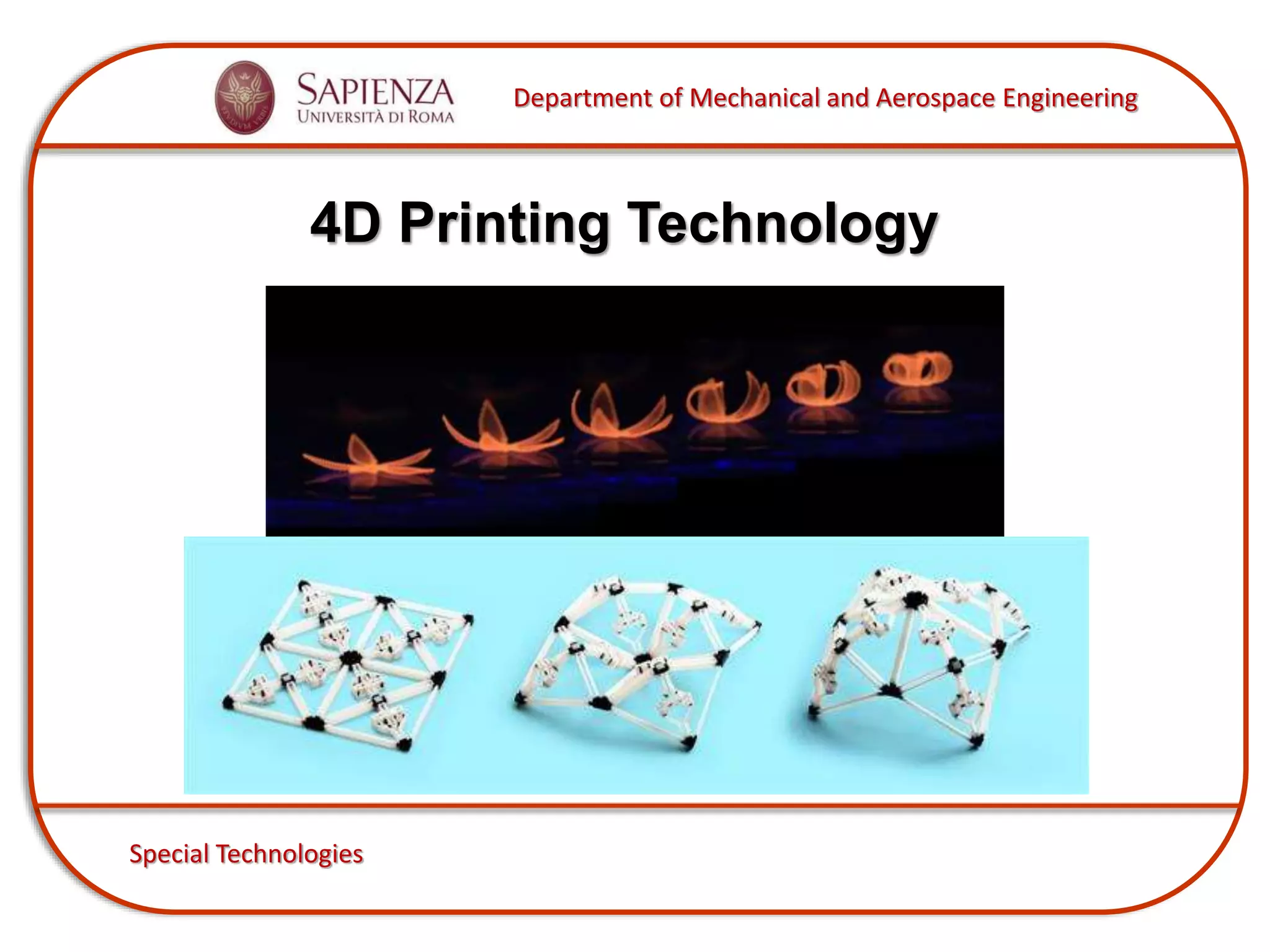

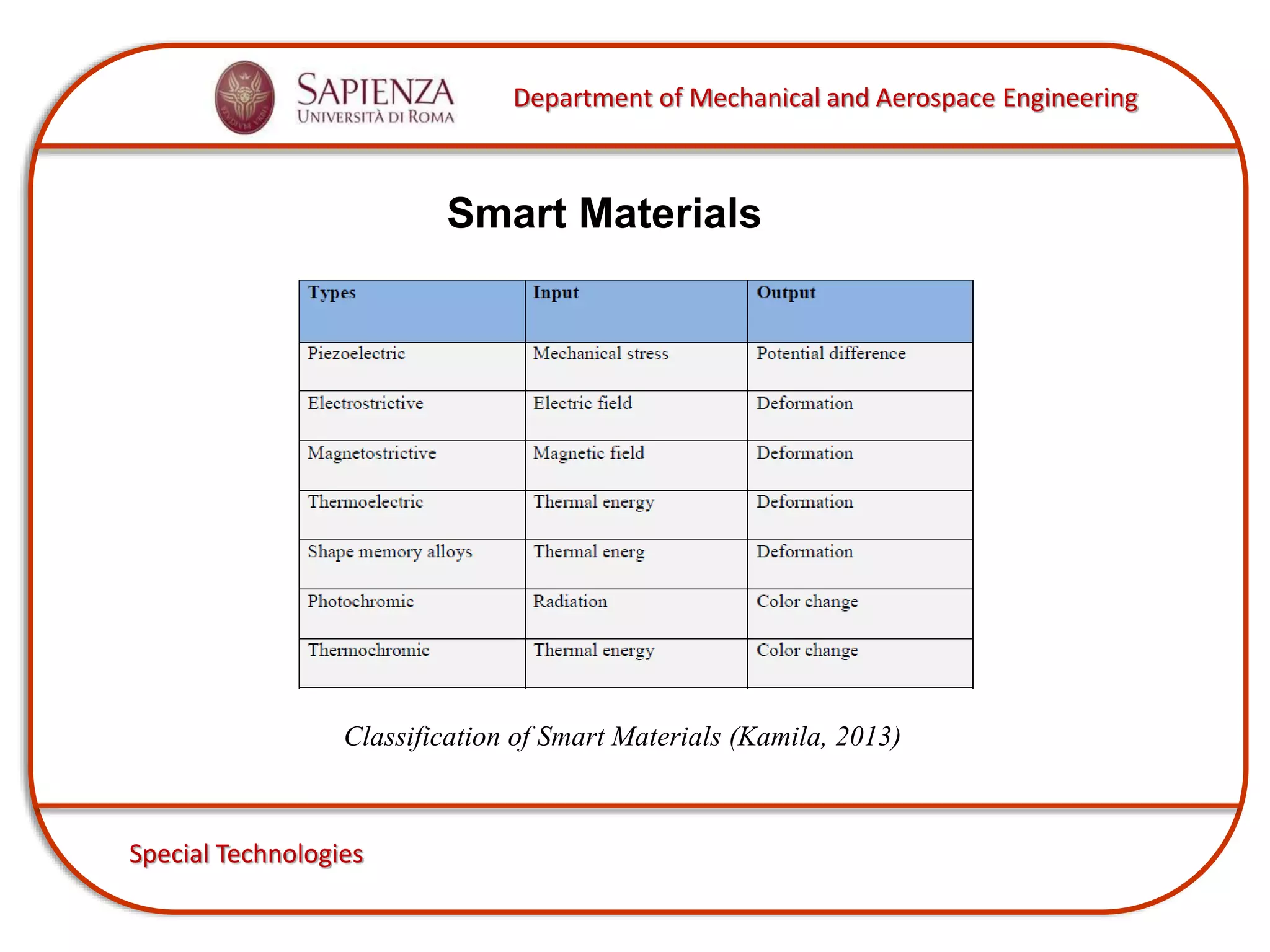

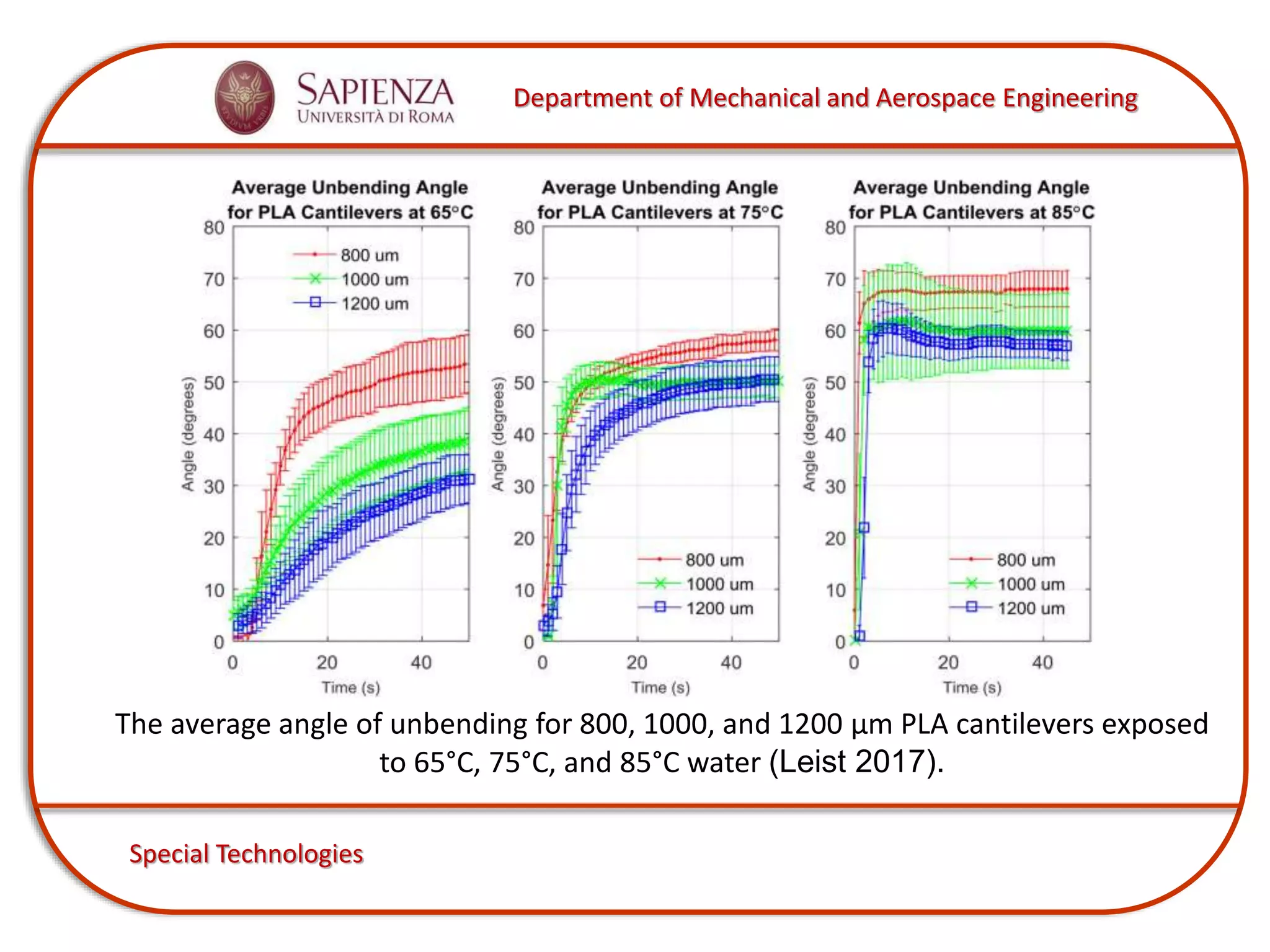

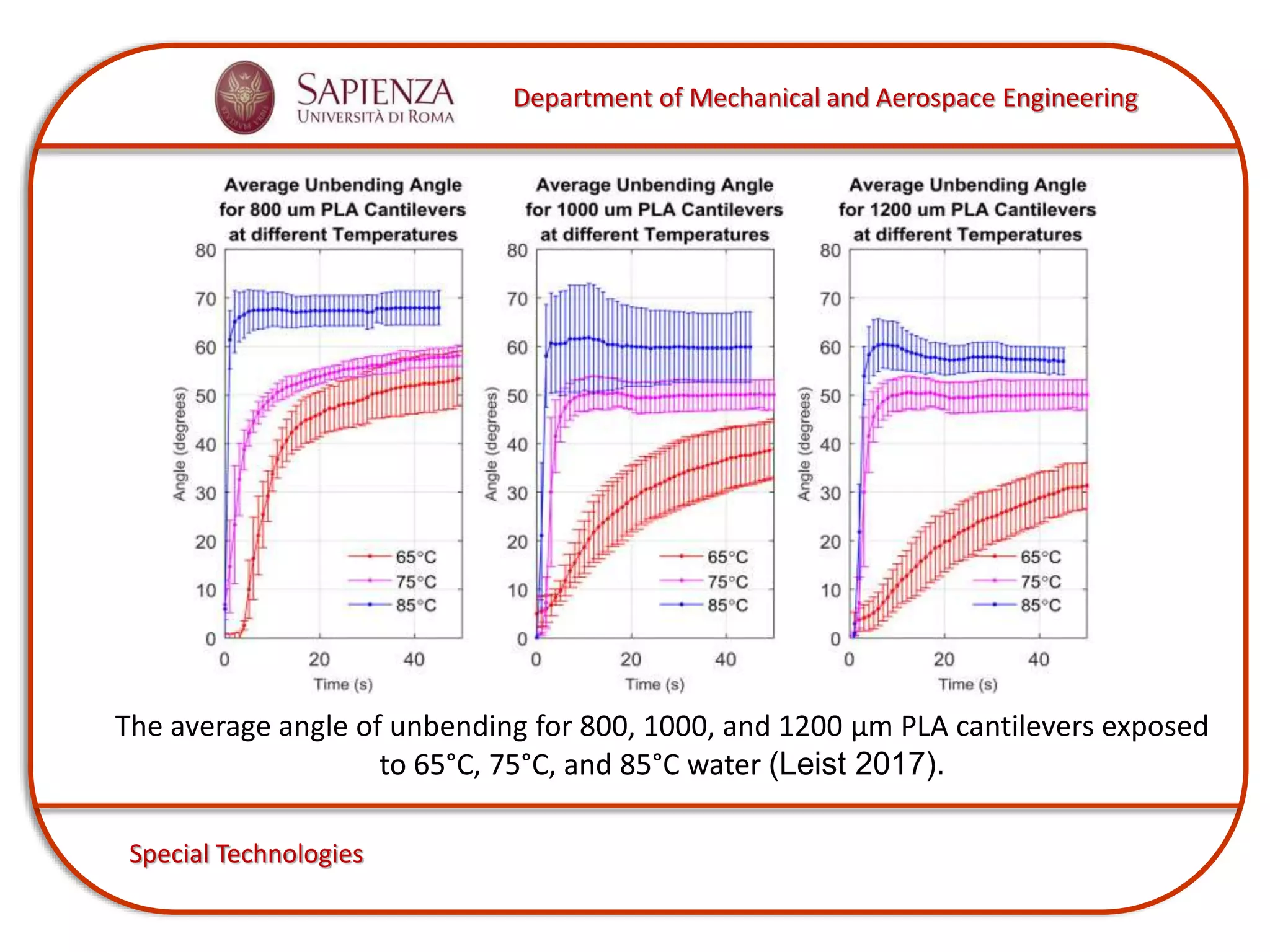

The document provides an overview of additive manufacturing, focusing on various 3D printing technologies such as stereolithography, fused deposition modeling, and selective laser sintering, along with their applications and materials used. It introduces the concept of 4D printing, which involves structures that can change shape in response to external stimuli, enhancing the functionality of 3D printed items. Additionally, it discusses the development of smart materials and specifics of their functionalities in 3D and 4D printing processes.