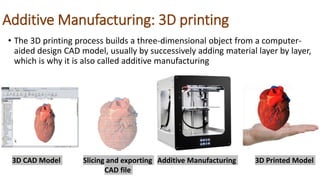

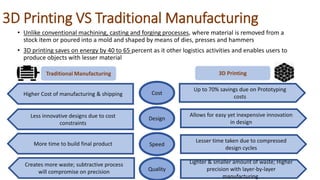

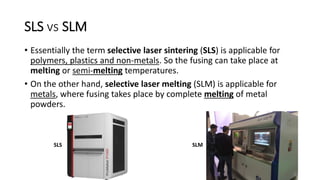

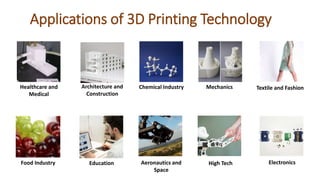

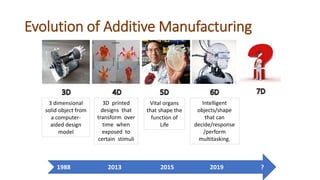

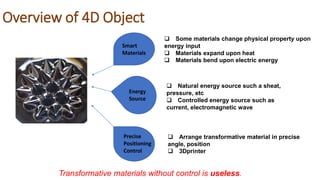

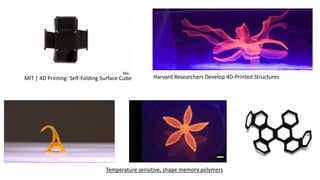

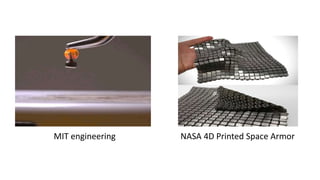

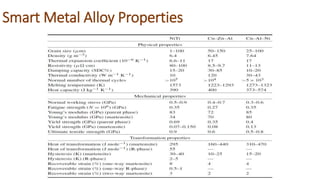

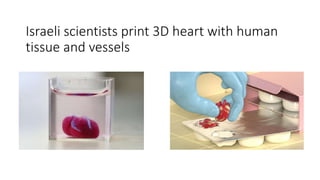

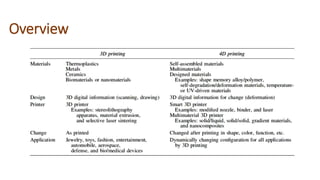

This document provides an overview of additive manufacturing and 3D printing technologies. It discusses 3D printing versus traditional manufacturing methods and describes major 3D printing technologies including stereolithography, fused deposition modeling, selective laser sintering, and selective laser melting. Applications of 3D printing in healthcare, construction, and other fields are highlighted. The evolution of additive manufacturing toward 4D printing and self-assembling materials is covered. Challenges and opportunities in the development of 4D printing are identified.