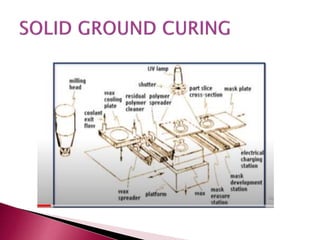

The SGC 3D printing process uses photosensitive resin hardened in layers, similar to stereolithography (SLA). However, SGC can produce many parts at once through a photomask that hardens an entire resin layer simultaneously. Each layer is then milled flat before the next resin layer is sprayed on. Wax fills empty spaces and provides support between layers. After building all layers, the wax is removed, requiring less post-processing than SLA. While expensive, SGC achieves high throughput production through multi-part fabrication and milling each layer for accuracy.