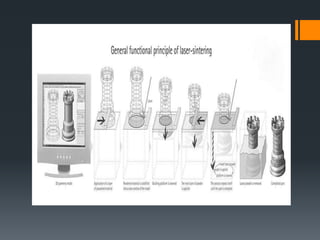

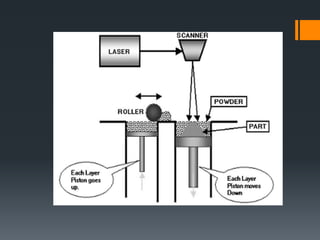

This document provides an overview of selective laser sintering (SLS), including its definition, principles, procedures, applications, advantages/disadvantages, and future potential. SLS is an additive manufacturing technique that uses a high-power laser to fuse powdered materials like plastic, metal, ceramic, or glass into solid 3D objects by selectively melting layers of powder according to a CAD model. SLS can produce complex geometries without support structures and allows multiple parts to be built simultaneously.