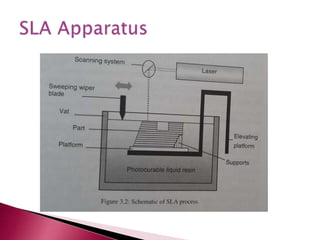

The document discusses stereolithography (SLA), an additive manufacturing technique. It works by using a laser to cure liquid photopolymer resin layer-by-layer, solidifying cross-sections defined by CAD data. The laser cures each thin layer, then the build platform lowers to allow a new layer of resin to coat the part before curing again. This repeats until the part is complete. SLA provides advantages like accuracy and surface finish and finds uses in prototyping, tooling, and low-volume production.