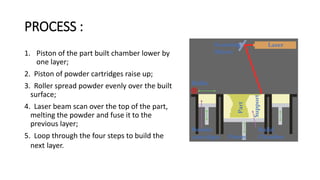

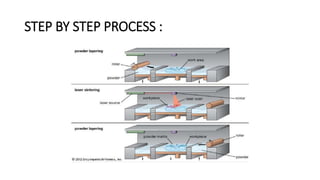

This document provides an overview of selective laser sintering (SLS), a 3D printing technique that uses a laser to fuse powdered material together layer by layer. It defines SLS, describes the basic multi-step process, and lists common input parameters and materials used. The document outlines key advantages like lack of support structures and fast printing, as well as limitations such as prints being brittle and prone to warping. A variety of applications are mentioned, including aerospace, medical, electronics, and automotive uses.

![• Messy

One of the most bothersome parts of the SLS printing process comes when the part has

been built and cooled – the cleaning process. When you retrieve the printed part from the powder

fin, it will typically be hidden inside a firm block of the unused powder. You will have to break apart

this block of powder and clean off the excess powder from the printed part using compressed air.

• Expensive

Ultimately, the most significant factor that is preventing SLS printing from becoming

mainstream technology is its cost. While it’s possible to get a high-quality FDM printer for less than

$500 and a beginner SLA printer for less than $1000, a desktop-scale SLS printer will set you back at

least $5,000.

[1 dollar = 71.99 rupees]](https://image.slidesharecdn.com/selectivelasersintering-190826121449/85/Selective-laser-sintering-11-320.jpg)