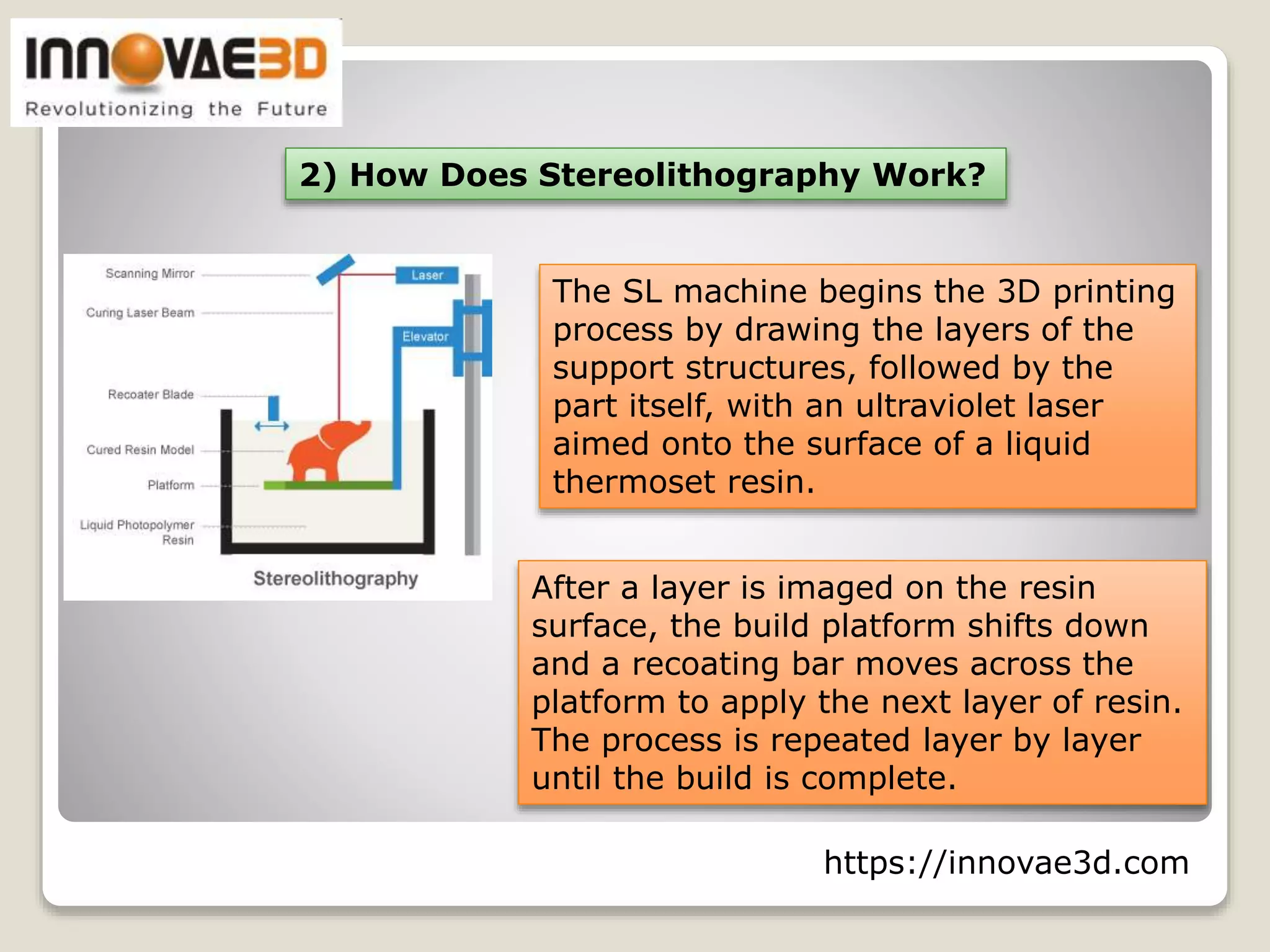

Stereolithography (SLA) is a 3D printing process that utilizes a computer-controlled laser to create detailed models and prototypes from liquid resin. This method is favored for its rapid production capabilities, high accuracy, and excellent surface finishes, making it ideal for concept validation and ergonomic testing. Common materials used in SLA include polypropylene, ABS, and polycarbonate, each offering unique properties for different applications.